How to reduce catalyst lifecycle cost, improve reliability

By Terry McTernan, PE, Cormetech Inc

Driven by the current regulatory climate and the growing dependency on natural gas for base-load electric generation, the majority of gas-plant fleets have made broad investments in selective catalytic reduction (SCR) systems. The successful operation of these systems requires monitoring, routine preventive-maintenance inspections, and periodic evaluations of the catalyst.

By taking a fleet-wide management approach, owners and operators can reduce catalyst lifecycle costs and insure reliable operation of their SCR systems. Improper management can result in permit violations and associated fines, operating restrictions, and bad publicity for the site. Under the Clean Air Act Amendments, air-permit regulations concerning NOx emissions are increasingly stringent, with levels as low as 2 ppm required in some locations.

Gas-fired fleets may include both combined- and simple-cycle units. In the former, the SCR modules are housed within the heat-recovery steam generator (HRSG) at an optimal temperature location, typically 600F-800F.

In a simple-cycle gas turbine, the SCR usually is installed in an expanded outlet duct immediately downstream from the turbine. Duct size is optimized to achieve the SCR catalyst reactor performance required. The short transition section from the turbine outlet to the SCR inlet often challenges system design. Turbine exhaust-gas temperature is often too hot to be efficiently treated by the SCR system. Many units rely on tempering air to cool the exhaust gas—typically to 900F or below.

An economic evaluation should be performed to determine if use of tempering air is warranted, or if a high-temperature catalyst would be a better option. Evaluation parameters include the following: capital versus operating costs, operating-time limits, volume of catalyst, duct size and back pressure, purge-fan versus tempering-air-fan costs, distribution equipment (tempering air and ammonia injection grid (AIG)), etc.

Recall that ammonia, a reducing agent, is injected into the SCR catalyst system and thoroughly mixed throughout the flue-gas stream to convert NOx to nitrogen and water. To accomplish the uniform delivery of ammonia, a piping network—or AIG—is installed upstream of the catalyst (Fig 1). Ammonia flow is regulated across the grid by a series of control valves. It is critical that the ammonia concentration within the exhaust gas be homogenous as it enters the SCR catalyst bed. This prevents the loss of unreacted ammonia—called “slip”—and eliminates areas starved of ammonia, which is conducive to localized, incomplete NOx reduction. Based on analyses of SCR operating data and catalyst samples, AIG and duct modifications may be warranted.

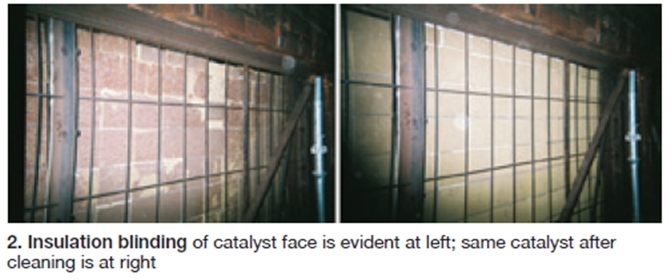

SCR catalyst systems may run with little attention for three to five years and gradually begin to show signs of performance loss and system wear. Several things can trigger a decrease in the NOx emissions control system’s ability to perform adequately. This includes HRSG tube leaks, blinding of the catalyst inlet by dislodged liner insulation, plugged ammonia injection lances, seal degradation, and/or abnormal turbine conditions (Fig 2). It is important to monitor equipment condition and evaluate performance demands against system capabilities to ensure reliable operation and avoid emergency shutdowns.Maintenance plan. SCR systems require routine oversight and must be maintained. Historically, many gas plants with SCRs operated cyclically, with extended periods between starts. This type of operating profile can accelerate ageing of catalyst system components, increasing the importance of regular inspections and preventive maintenance.

Catalyst condition should be evaluated regularly. Catalyst is the most expensive part of the SCR and its performance can vary widely over the system’s lifetime. Plants where catalyst has been operated and maintained properly typically report long life prior to replacement. Responsible planning and auditing can increase the useful lifetime, thereby effectively reducing SCR operating costs and avoiding the large, unbudgeted expenditures associated with buying new catalyst. For the most effective program, gas-plant owners should focus on the long term and evaluate SCR life-cycle costs.

Fleet-wide lifecycle management

For plant owners and operators, a baseline survey of each SCR unit within the fleet serves as the logical starting point in the development of an overall catalyst management process and strategy. This fleet-wide approach leads to a comprehensive and efficient management plan that will lower costs and make decision-making more efficient. It is superior to managing various SCR systems at different plants individually.

A fleet SCR manager should be chosen. His or her job is to assure the compliance of all environmental air permitting requirements by creating a comprehensive baseline for each site and developing an ongoing, preventive maintenance strategy. Since SCR equipment is custom-manufactured for the unique demands of each plant, the fleet manager must take into account current and future permit conditions and operating demands on each unit.

Balancing the requirements of each SCR system in the fleet can be challenging. A system can reduce NOx by greater than 95%, but, when the efficiency of the SCR is pushed beyond 85% and—or, if—the outlet emissions are less than 5 ppm, the system becomes much more sensitive to several independent system parameters. These include overall catalytic potential, effective ammonia injection/mixing in the flue-gas stream, flue-gas characteristics for inlet NOx, velocity, and temperature distributions. Issues can be addressed by high-efficiency SCR designs with system modeling, flow correction devices, enhanced catalyst volumes, and a robust ammonia injection grid design.

As plant equipment is upgraded, repaired, or otherwise modified, the performance environment for reliable emissions control can be affected. Understanding these potential impacts to the SCR system is essential and should be studied. For example, components of the ammonia delivery system may deteriorate over time. The system may reach a point where it can no longer perform adequately with aging catalyst.

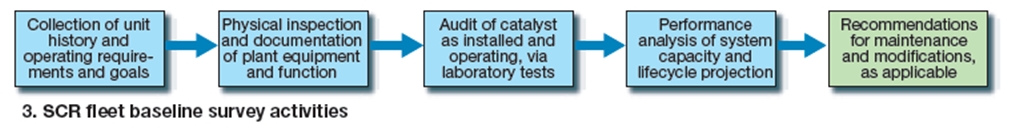

Baseline survey. A properly executed baseline survey, conducted by a qualified catalyst management provider, should fully assess the current condition of each SCR in the fleet. Surveys must be site-specific, since each location will have its own unique history and permitting requirements. The survey should begin with each site’s air permitting requirements and goals, which can vary significantly based on the age of the unit, geographic location, cost of ammonia, etc. And, it should identify the SCR system supplier and include a review of the site’s operating history (Fig 3).

Next, site maintenance records, catalyst test reports, and control-room feedback should be assembled. Finally, a documented physical inspection of the SCR catalyst systems is recommended to help verify the historical records and equipment status.

Management plan

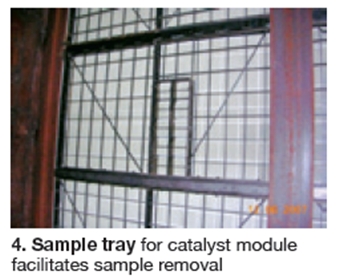

It is important to verify that testing be conducted under conditions that closely match the actual operating conditions of the SCR system, not under a set of theoretical or standardized design conditions. The sample should represent a typical cross section of the SCR and the operating history should be known. A convenient method for sampling purposes is to incorporate an easily removable sample tray within the catalyst module, as shown in Fig 4.After the data are collected and a physical inspection of the plant is complete, consider diagnostic testing of the catalyst. Laboratory testing is conducted to determine the catalytic potential of the SCR reactor bed and to predict its ability to continue to meet performance requirements.

The samples in the tray can be quickly removed when the unit is offline. This way, an operator can avoid drilling into the catalyst to extract core samples. Note that core samples typically are not required for units with homogeneous honeycomb catalysts, but may be recommended for units with alternative-type products and/or ones that have a localized problem—such as a tube leak.

Analyses should be conducted in a controlled laboratory environment using custom-built and validated SCR catalyst test equipment. This will accurately determine how the catalyst is performing. The fleet manager can then compare its performance to previously tested elements.

The assessment of field operating data is important, because it determines the performance requirements of the SCR, operating conditions, test conditions for the laboratory performance test, and the performance threshold. If field data change relative to previous evaluations, the test conditions and/or the performance threshold also may have to change. An analysis of field operating data, together with laboratory test results, can determine if flue-gas bypass and/or an ammonia-to-NOx imbalance is adversely affecting SCR performance.

In the prediction of remaining life, an analysis of the trends in laboratory test results from a series of audits and field operating data over time is compared with data from similar units and expectations based on unit operating history. From this comparison, a prediction is made of the remaining life where the SCR is expected to meet performance requirements.

If the factors that affect catalyst deactivation do not remain consistent throughout the estimated remaining life, the future rate of deactivation will differ from the current observed trend. For this reason, periodic auditing to measure potential changes in the deactivation trend is recommended to improve the accuracy of remaining-life projections.

Recommendations going forward

For systems nearing end-of-life (from a performance standpoint), but with meaningful remaining catalytic capacity, equipment system improvements may be possible. For example, a plant may be able to redesign or upgrade the ammonia injection system. The catalyst management organization may employ CFD modeling as part of the optimization process, which can result in a reduction of ammonia usage and improve overall emissions performance.

If survey results and diagnostic testing reveals that remedial measures to the catalyst bed are necessary, or that catalyst must be replaced, the catalyst manager has several options to recommend to the plant. SCR systems that contain catalyst with substantial remaining catalytic activity may be candidates for refurbishment of the catalyst bed. This is a good option for a plant that has deteriorated seals, module wear, and distortion that cannot be repaired by maintenance action.

When SCR catalytic potential has degraded the point where it can no longer meet plant needs, the entire SCR reactor bed must be addressed. Options include: full replacement, partial replacement, integrated reuse with new catalyst, and regeneration.

Each method has its advantages and disadvantages and must be considered within the context of a given unit, plant, and fleet. For example, regeneration uses a special, aqueous-based chemical solution to remove certain types of contaminants. This might be a viable option, if the problem can definitely be solved by regeneration and the long-term performance can be guaranteed. Additionally, any work, including replacement and integration, must be feasible within a given outage period.

Partial reuse is another possibility and may involve the integration of an advanced module design, which can lower total-pressure loss. As with other approaches, site-specific goals and constraints must be considered. Ultimately, the best approach is the one that will result in a robust SCR system with long-term, guaranteed performance.

Final thoughts. To successfully operate an SCR, the fleet manager must monitor the system, perform routine inspections, and periodically evaluate the catalyst. For simple- and combined-cycle gas plants, this effort includes the continual review of operating data, NOx reduction, ammonia slip, pressure loss, and ammonia usage. By taking a fleet-wide approach to managing these tasks, owners and operators can benefit from reduced SCR lifecycle costs and insure the reliable operation of their SCR catalyst systems. ccj