Bremco Inc’s Reg and Bob Morse closed out the 2014 Combined Cycle Users Group meeting with a case history on the replacement of main steam valves for F-class heat-recovery steam generators. Their presentation illustrated the extensive, and expensive, effort required to replace large boiler valves. Likely, it will make you think twice about purchasing valves of any size for new HRSGs, or replacement valves for existing units, based on cost rather than on quality.

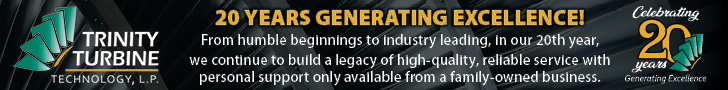

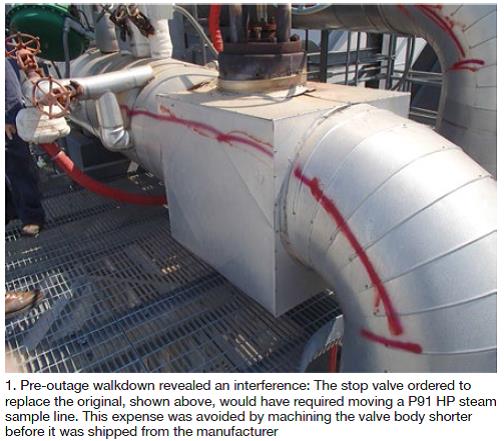

Issues with the large P91 valves on four HRSGs serving two 2 × 1 combined cycles at one plant dictated their replacement. Bob Morse, who managed the project onsite for contractor Bremco, began his narrative with the site visit conducted to plan the job. The original valve (Figs 1, 2) received steam from a 16-in. line on the boiler side and discharged it to the 12-in. HP steam system. The replacement valve purchased by the plant owner/operator was of a 12 × 12-in. configuration and required an inlet reducer.

Issues with the large P91 valves on four HRSGs serving two 2 × 1 combined cycles at one plant dictated their replacement. Bob Morse, who managed the project onsite for contractor Bremco, began his narrative with the site visit conducted to plan the job. The original valve (Figs 1, 2) received steam from a 16-in. line on the boiler side and discharged it to the 12-in. HP steam system. The replacement valve purchased by the plant owner/operator was of a 12 × 12-in. configuration and required an inlet reducer.

The value of a comprehensive job walkdown was in evidence almost immediately. As ordered, the new reducer and valve would be longer than the original 16 × 12-in. valve and require the relocation of an HP-steam sample line. This would have been labor intensive and quite expensive, Morse said, explaining to the editors the work associated with field modifications of P91 piping—especially in locations difficult to access. The economical solution was to have the valve manufacturer machine the valve body shorter to avoid the interference.

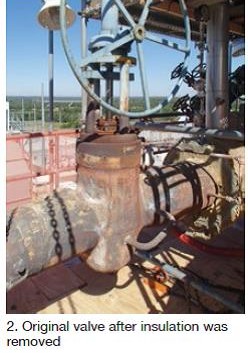

The reducer was welded to the valve at ground level in a plant area protected against the elements. A proper “field shop” benefits proper welding and heat treatment, which must be done to exacting code standards (Fig 3). This work was completed, and weld quality verified, prior to unit shutdown to minimize the outage time required for valve replacement.

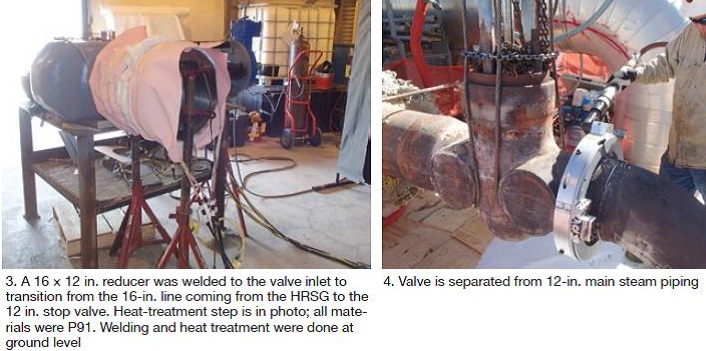

Another benefit to the pre-outage assembly of reducer and valve was that an exact measurement could be made to guide cut lines for removing the original valve, Morse noted (Fig 4). After that valve was cut out of the line, piping on both sides was counterbored and then beveled so the IDs of the pipe and the reducer/new valve would match up (Fig 5).

Lifting and lowering any heavy object to/from the top of a boiler the size of an F-class HRSG is not a difficult task with the proper crane. However, the crane required is expensive and the longer it is onsite the more costly the job. Bremco and its customer optimized the hours required for the crane, and for welding, heat treatment, QA, etc, by integrating the valve replacement work for the four boilers.

This brought the complete job in at about nine days, or about five days less than if each unit had been handled on an individual basis, Morse thought. Another thing Bremco did to mitigate schedule and cost risk, was to run “informational” x-rays at key points during the welding process. Doesn’t cost much, Morse said, for the assurance that a complex weld will not require rework after its completion.

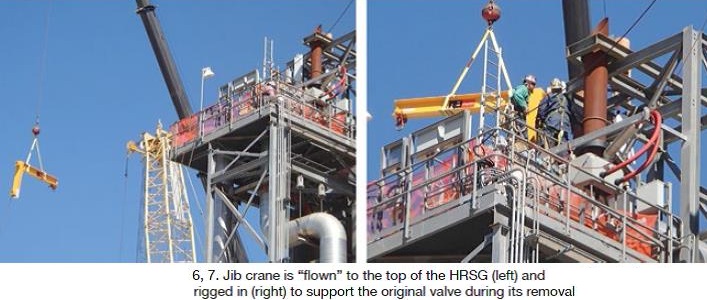

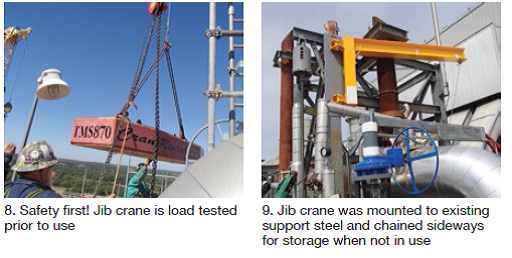

Installing a jib crane or davit arm at the top of each boiler helped to reduce the time the conventional crane was required (Fig 6). For example, it was used to support the original valve during its removal. The plant bought the davits and conducted the structural analysis required (Fig 7). Load tests (Fig 8) confirmed the boiler-top cranes “fit for duty.” After use the davit arms are chained sideways for storage (Fig 9).

Fig 10 shows the nominal 2-ton valve/reducer being lifted to the top of the HRSG for installation. This is a delicate process because P91 cannot be subjected to any abnormal stresses during handling/welding of the equipment (pipe, valve, etc) once the process of welding and/or machining starts, until after post-weld heat treatment is completed. In Fig 11, note the system of chain supports to hold the valve/reducer level and in position for welding without any side-to-side stress. CCJ