|

1. Classic Frame 5 generators typically arrive at the shop in poor condition. Mechanical, electrical, thermal, and environmental aging influences have taken their toll. Stator and rotor winding insulation systems usually are obsolete. Plus, retaining rings, collector rings, core iron, and the end-basket support system are dated and should be upgraded. |

|

2. A classic commonly contains asphalt-mica stator windings. The straight-section outer binder, strand insulation, and/or end connection putty may contain asbestos; test prior to demolition. If positive, use only trained abatement specialists. As the stator windings are extracted, critical dimensions are taken for the engineering and redesign process. |

|

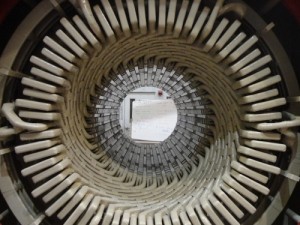

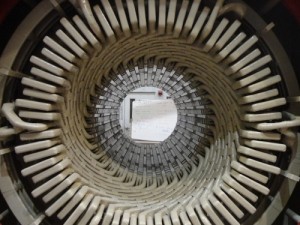

3. Once stripped of the original windings, the stator housing and core iron are grit-blasted clean. Great care is required during this operation, because the stator laminations are susceptible to “smear” damage. Perform a near-flux core loop test to requalify the iron for reuse. |

|

4. A full core replacement can be performed with either stamped punchings or laser-cut laminations. The lamination steel used should be either grade M6, Cold-Rolled Grain-Oriented (CRGO), or M15, Cold-Rolled Non-Grain-Oriented (CRNGO), with C5 core plating as the interlaminar insulation. |

|

5. The original two-turn full diamond coils are upgraded to two-turn, 360-deg Roebel half-coils, which are far superior to the original windings in many ways, including these: They have more copper (lower I2R losses), more conductors in-hand (lower eddy-current losses), and a Roebel transposition (lower circulating-current losses), as well as a modern resin-rich mica thermosetting insulation system. |

|

6. The new and improved windings are installed into the stator core iron together with the following upgrades: End-basket support system, vertical slot fillers, side packing, stator slot wedge system, encapsulated end connections, circuit ring bus, new RTDs, new heaters, a flux probe, and partial-discharge monitoring system. |

|

7. A comprehensive acceptance program is conducted following a stator-winding upgrade and includes successful completion of an El CID core test, wedge-tightness mapping, insulation resistance, Polarization Index; controlled over-voltage; ac and dc high potential, power factor and tip-up, and phase resistance. |

|

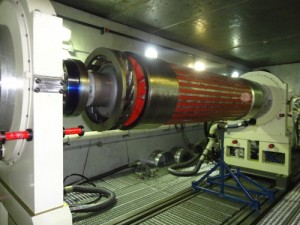

8. The rotor is dismantled down to a bare forging, taking steps to avoid the release of asbestos-bearing materials, if present. Copper samples are removed from the main field winding and lab-tested for composition, tensile strength, hardness, and yield strength. Main field windings generally are suitable for reuse. |

|

9. Rotor components—such as the rotor body forging, retaining rings, blower hubs, and rotor body wedges—are cleaned down to grey metal. Each individual part is subjected to requalifying nondestructive testing, which may include dye-penetrant, ultrasonic, eddy-current, and magnetic- particle examinations. Non-conforming parts are either repaired or replaced. |

|

10. The reconditioned and requalified main field coils are wound back into the rotor-body forging. The latest turn-to-turn and ground-wall insulation systems are incorporated into the process. Slip-planes, critical to unimpeded axial thermal expansion and contraction of the windings, are designed into the upgraded main field winding system. |

|

11. Specially designed and fabricated slot and end-winding compression fixtures are installed on the newly installed coils, forming a symmetrically round and dimensionally concentric main field winding. The rotor is then induction-cured, to set and stabilize the associated adhesives while seasoning the windings. |

|

12. All new top creepage blocking is installed along with the rotor body wedges and a new permanent end blocking system. Should resin-load materials be used, the end windings are compressed once again, and the rotor windings are subjected to a second and final induction curing process. |

|

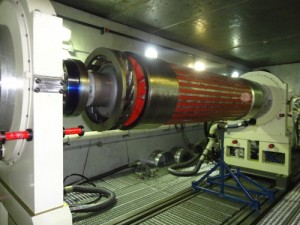

13. The rewound, reassembled, and fully upgraded rotor is placed in the high-speed balance facility. There it is balanced to operational speed, subjected to a minimum 10% over-speed run, and at-speed electrical testing—including insulation resistance, ac impedance, RSO and/or flux probe. |

|

14. The generator rotor now is completely upgraded, uprated, and “zero houred.” With all new turn-to-turn, ground wall, and retaining-ring insulation systems, modern 18Cr18Mn retaining rings, and new collector rings, the classic Frame 5 rotor is better than when it was new and ready to begin its second life cycle. |

|

15. The Frame 5 generator is a true classic in every sense of the word: simple in design, rugged in construction, and easily acceptant of modern upgrades and uprates. Rebuilding of vintage machines typically makes better economic and business sense than buying new. Owners can expect years of relatively maintenance-free service. |