Performance, flexibility upgrades boost profitability in dynamic market

Lawrenceburg Power operates in the PJM Interconnection. Plant owner Lightstone Generation wanted a reliable, cost-effective upgrade to simultaneously maximize capacity payments and align combustion and hot-gas-path (HGP) inspections at a 32,000-hr maintenance interval.

The plant operates in a shale-gas region and can receive fuel from multiple sources that may contain high levels of ethane. Inconsistent fuel properties were identified as the expected root cause for some fuel-nozzle tip burnouts that caused forced outages on multiple units at the site.

A challenge that Lawrenceburg faced was identifying upgrade solutions with predictable impacts on heat-recovery steam generators (HRSGs), the steam turbine/generator (STG), and balance-of-plant (BOP), as well as on startups and shutdowns of the power blocks.

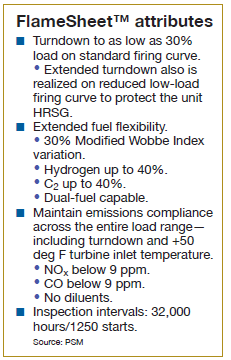

Lawrenceburg Power entered into a long-term service agreement (LTSA) with PSM in fall 2017. In March 2018, Power Block 1 was shut down to implement the first two PSM FlameTop upgrades for addressing the plant’s operational challenges. FlameTop combines PSM’s FlameSheet™ combustion system (sidebar) and GTOP3.1 (Gas Turbine Optimization Package).

Lawrenceburg Power entered into a long-term service agreement (LTSA) with PSM in fall 2017. In March 2018, Power Block 1 was shut down to implement the first two PSM FlameTop upgrades for addressing the plant’s operational challenges. FlameTop combines PSM’s FlameSheet™ combustion system (sidebar) and GTOP3.1 (Gas Turbine Optimization Package).

Converting the block’s gas turbines from DLN2.6 to FlameSheet combustion systems increased the allowable variation in the fuel’s Modified Wobbe Index (MWI) from 10% to 30%.

The GTOP3.1 package, which includes upgraded hardware to increase compressor flow and reduce combustor pressure drop as well as the amount of turbine cooling and leakage air required, was installed on each GT to improve performance.

FlameTop mode switching logic and AutoTune also were incorporated so the plant could both maximize peak-fire capability and achieve the desired 32,000-hr maintenance interval. PSM AutoTune provides real-time tuning of the gas turbine fuel splits to maintain stable combustion dynamics while managing gas turbine NOx production throughout the plant’s dynamic Ohio River Valley weather patterns.

Lawrenceburg Power engaged an engineering firm to review the new conditions that the upgrade might present to the HRSGs, STG, and BOP equipment. In addition, a steam-turbine contractor was used to perform a pre-outage performance test and to make recommendations on opening the diaphragm clearances to allow the expected increase in flow through the machine—a benefit of GTOP3.1.

The engineering firm also performed a review of HRSG purge times, eventually settling on a 6-min decrease to maintain required volume of air changeout. The 6-min reduction in purge time, together with the FlameSheet combustors not requiring a reduction of speed to flame and warmup but rather flame and warmup at purge speed, provides a significant reduction in start time.

A study was conducted using the site’s high-fidelity simulator to ensure changes in startup and shutdown procedures would not introduce a safety issue or cause equipment damage. Numerous simulated startups and shutdowns were performed by site personnel and PSM engineers to refine logic changes and minimize stresses on BOP equipment and the STG. New startup and shutdown procedures were developed prior to the first fire of the upgraded gas turbines.

By incorporating FlameTop, the plant gained nearly 11% in output in Peak 3 firing mode. Each GT upgrade was commissioned with six operating modes—including extended maintenance (40k hr), maintenance (32k), performance (24k), peak 1 (10 deg F over peak firing temperature), peak 2 (20 deg F), and peak 3 (30 deg F).

Steam-turbine diaphragms were modified to accommodate the increase steam flow thereby increasing power-block output. Staff is managing operation in each mode to ensure that the HGP will occur at 32k actual hours of operation.

The site has realized significant ammonia savings (approximately 50%) because of the reduction in turbine NOx emissions attributed to FlameTop. The units also turn down an additional 10 to 15 MW as compared to pre-outage conditions and on a reduced isotherm which helps to maintain BOP equipment health while operating at minimum load.

Commissioning of the upgrade confirmed simulated startup logic, startup procedures, optimized mode transfers, and refined fuel splits for stability. End result was a combined-cycle startup optimization that reduced start times by 30 minutes (hot) to 45 minutes (cold) without additional stress to the BOP. No hardware issues attributed to shale-gas fuel property swings have been noted since the FlameSheet installs.

Learn more from our featured solutions provider

Training, automation, standardization streamline calibration processes, cut cost

Instrument calibration at Lawrenceburg Power was a labor-intensive process involving paper-based procedures resident in a Microsoft Access database. Based on a manual review and assessment of the calibrations required, a tool set could be assembled from the vast inventory of test equipment the plant maintained—including gauges, meters, decade boxes, etc.

Execution of a calibration required the technician to manage the multiple pieces of equipment while referring to the printed calibration procedures, determining pass/fail status, and recording the results on the hard-copy document. The documents served as the permanent record and were eventually stored in a physical filing cabinet.

Although this system worked, staff identified several problems with it, including the following:

-

- User controls were non-existent, questioning data integrity.

- A lack of standardization caused inconsistent calibration results.

- Clerical errors were associated with hand-written records and the paper-based workflow.

- Calibration was time-consuming, introducing the opportunity for process uncertainties.

Maintenance technicians at Lawrenceburg are all multi-craft and responsible for a wide range of daily tasks. Instrument calibration is just one of those assignments. For this reason, and the sheer amount of instrumentation the technicians manage—about 3600 components, 300 of which require critical calibrations during outages—they needed a data management system that was easy to implement and use.

Also, the responsible personnel wanted to standardize tools and reduce the considerable amount of equipment required and had to be maintained. Ensuring NIST (National Institute of Standards and Technology) traceability was an absolute requirement and had to be easily enforced.

To improve data integrity, the technicians aimed to minimize the opportunities to “cheat the system” or “pencil whip.” They also sought a solution that would provide a professional calibration certificate, audit trail, and provide analytics of the results—such as data trending and hysteresis errors.

The MC6 multifunction documenting calibrator from Beamex Oy Ab was the solution implemented. No matter who uses the system, the work is performed and results are recorded similarly, improving system reliability and confidence in the data. Additionally, the software allows printing of custom-designed calibration labels.

Thus far, the results have included the retirement of 80 measurement standards which saves a significant amount of money in recertification costs, implementation of a paperless system that is intuitive and easy to learn, improved data integrity and reliability, exposure of shortfalls in calibration of mission-critical instrumentation, and time saving of up to 50% on calibration work.

Plus, technicians were able to integrate some of the plant’s existing standards with the Beamex technology. Example: A HART Scientific temperature dry-block used with the MC6 to automate temperature calibrations. By using a more accurate system, technicians learned that many of Lawrenceburg’s switches and drum levels were out of tolerance, which could have caused an emergency outage and cost the plant dearly if not resolved quickly.

Metrology training boosts staff confidence in performing calibrations

Prior to implementation of Lawrenceburg’s new calibration process described in the text, plant personnel had no formal metrology training. This was conducive to inconsistent calibration results and made employees tasked with instrument calibration uncomfortable.

The plant had a large inventory of calibration equipment that required annual recertification and once recertified would sit in a drawer for up to a year. Technicians wasted time looking for the correct equipment, hoses, and fittings to perform calibrations.

Solution to the issue of inconsistent calibration results was to develop a training program so all technicians would gain a better understanding of metrology and perform calibrations in the same manner.

Another goal was to standardize tools and reduce the considerable amount of equipment required to be used and maintained, as well as to reduce the time it took to locate the proper equipment to perform the calibrations.

The second goal was achieved by arranging field calibration equipment in sets (two sets were made) and organizing them in the instrumentation shop for easy accessibility. Senior Technician Ron Cash designed and built a calibration test bench with all the necessary equipment to train technicians on calibration procedures.

One of the things he did was to convert all the field devices and calibration equipment to Ralston quick-test type fittings and then assemble two fitting and hose sets that will work for any calibration being performed.

Today, with technicians more comfortable performing their calibration duties, the accuracy and repeatability of results have improved markedly.

Fire-protection upgrades make Lawrenceburg a safer place to work

Lawrenceburg Power’s fire alarm system consisted of several alarm panels from different manufacturers, all integrated into a main panel in the control room. When an alarm was received it was time-consuming and difficult to distinguish what device triggered the alarm because of all the integration.

Staff decided to replace the entire fire alarm system with Notifier NFS2- 3030 panels, Onyx work station, new signaling devices, and speaker/strobes to have a fire/mass notification system that would meet NFPA 72: National Fire Alarm and Signaling Code.

The advantage of a mass notification system is that it immediately informs end users of a situation and how to proceed. Notifying occupants via the mass notification system is done by email, loud speaker/intercom, and graphics-board messaging using a message board from Light Engineered Displays Inc.

Lawrenceburg’s mass notification system is used for any emergency application—including fire, weather, natural-gas leaks, chemical spills, medical emergency, intruder, terrorist situations, generation alerts, start/lunch/stop times, etc.

When an alarm comes in today, the operator’s screen automatically changes to the screen where the device is located, the device flashes and changes color based on the event, and the message is displayed and played over the system. The message tells you the type and location of the situation and informs everyone except the responders what to do and where to report to. The operator can just look at the screen and know which area and device that he/she needs to direct the responders to.

The system is set to alarm a minimum of five times; it alarms on a fire and gas leak until reset by the operator allowing offsite responders the ability to see the location and type of event on a display board as they enter the property. Lawrenceburg’s fire detection/mass notification system monitors the control room, electrical rooms, transformers, black-start generators, gas turbines, etc. The detection systems used are heat, smoke, and combustible gas; the plant controls FM-200, CO2, dry pipe, deluge and pre-action fire suppression systems, and monitoring of wet-pipe systems.

The second part of the project was to replace the gas-turbine Chemetron Fire Systems Micro 1 EV control panels. Chemetron had discontinued repairing the Micro 1 EV control boards in April 2008 and obsoleted the product shortly thereafter. The plant had four of these panels and previously had experienced a CO2 dump because of a failed control board.

With few spare parts available, Lawrenceburg received some spares from its fire service vendor which had been taken out of service at other locations. The plant had experienced many false alarms from these systems. They had limited memory and when not properly cleared out and fully reset would sound the alarms.

An issue with many GE 7EA gas turbines installed in the 1990s and early 2000s is that the 45FTX fire protection shutdown relays are wired in parallel. These seven (or nine) 120-Vdc relays located in the PEECC (packaged electrical and electronics control compartment) fire- protection relay cabinet, activate from the each of the Chemetron fire-system control-panel Aux 1 relays and from the Chemetron discharge pressure switches.

A problem occurred in some locations where repeat actuation of this circuit during a routine CO2 inspection damaged the Aux 1 relay base because of the momentary excessive current draw of these seven (or nine) relays. The Aux 1 base, soldered to the main Micro 1 integrated-circuit board, cannot be replaced in the field, thereby requiring a complete Chemetron Micro 1 control panel replacement, which is no longer available.

Staff was concerned this could be a possibility on Lawrenceburg’s 7FAs as well, and the plant replaced them with the same Notifier NFS2- 3030 panels used in the fire alarm system described earlier. New wiring and some conduit also was installed because of the extreme heat this equipment is exposed to. This was integrated into the main fire control panel and it also populates on the Onyx work station.

The final part of the upgrade was to install pre-discharge pneumatic time-delay systems on each of the gas-turbine CO2 systems in accordance with NFPA 12. The 2005 edition of this standard requires the implementation of pneumatic time delays and pneumatic pre-discharge alarms into both new and existing CO2 extinguishing systems where the agent is introduced into normally occupied or occupiable spaces.

Dryers improve performance of hydrogen-cooled generators

Most manufacturers of hydrogen-cooled generators recommend having dryers to remove moisture from the gas. When wet, hydrogen loses its beneficial properties for generator cooling, becoming more dense and increasing windage losses. These losses take the form of additional heat production during generator operation and increased fuel requirements to generate the same output.

Moisture also reduces the ability of the generator gas to remove heat from the system, the specific heat of water vapor being lower than that of hydrogen. Recall, too, that some generator failures have been tied directly to moisture in the unit. Perhaps most notable were the failures attributed to stress corrosion cracking in the retaining rings. However, there are other failure modes either caused by, or enhanced by, excessive moisture in the generator.

Lawrenceburg Power’s six hydrogen-cooled generators were supplied without dryers. An in-situ robotic inspection of one gas-turbine generator in one of the two 2 × 1 power blocks revealed red dust on one side of the core iron while the robotic trolley was moving axially down the length of the bore. The dust was found in what appeared to be concentric bands spaced at certain locations down the bore.

In 7FH2 generators like those at Lawrenceburg, such bands of red dust typically are indicative of belly-band looseness.

Hydrogen coolers were removed from the generator to inspect the back-iron condition and get a better assessment of how loose the core iron was. The inspection was not confined to where the heaviest concentrations of red dust were identified during the in-situ inspection, but rather to assess the overall condition of accessible core laminations.

The inspection photos revealed red rust in different slots and in different positions of the robotic trolley as it took pictures. These slots all reveal red dust at approximately the same location and position, indicating rings (most likely where the belly bands are located).

After removing the hydrogen coolers on one of the two gas turbines being inspected, the belly bands were checked for tightness. None was found out of spec. With no looseness observed with the knife check, staff concluded that the rust indications were likely from moisture collecting in those areas over the history of the plant.

The plant leadership team decided to forego further testing on the second gas-turbine generator and worked with supplier Lectrodryer to install hydrogen dryers on the power block’s three generators during the outage.

Since installation of the dryers, the plant has been able to maintain a hydrogen dewpoint of minus 20F to minus 50F on all three generators. EMI testing on the generators recently confirmed improvement over testing in prior years, with the only modification being the addition of the dryers. Lawrenceburg was scheduled to install the same dryers on the three generators in the second power block during spring 2019.

Burner management system upgrade improves reliability, facilitates troubleshooting

Design of the burner management systems (BMS) supplied with Lawrenceburg’s HRSGs were difficult to troubleshoot when a component failed, causing longer-than-expected downtimes and added repair cost. Compounding the difficulty, the original Fisher 399A regulators were obsolete.

The system safety design incorporated two “slam-shut” stop valves and a vent valve (double block and bleed) on the pressure reducing station. If the BMS became unstable and a trip initiated, the slam-shut valves would close and the vent would open. This would stop the gas flow instantly, causing system backpressure to spike. By design, the regulator diaphragm is in the flow path and when subjected to high backpressure it was the most likely component to fail.

Cornerstone Controls Inc, an Emerson partner, was contacted to review the BMS failures. Working together, Lawrenceburg and Cornerstone personnel determined that the Fisher 399A regulators should be replaced based on how the BMS station operates. The solution selected was two Fisher EZH pressure-reducing regulators. In addition, the system required one Universal Vortex dual-path pilot-gas heater and one Fisher 627 regulator.

The new pressure-reducing station is configured as a “wide-open monitor.” In this arrangement, the upstream working regulator controls system outlet pressure. The downstream monitor regulator senses a pressure lower than its set point and tries to increase outlet pressure by going wide open.

If the working regulator fails, the monitoring regulator takes control and holds the outlet pressure to the outlet-pressure setting. The EZH regulators have metal trim and are not affected by system trips. The piping system also was redesigned to allow for easier troubleshooting.

Since the BMS was upgraded, gas pressure is more stable and the plant has had no failures associated with the burner management system.

Switch to self-contained hydraulic valve operators improves turbine-bypass performance

Top performance from steam-turbine bypass systems during startups, shutdowns, and trips at combined-cycle plants is critical for achieving the operating-flexibility and availability goals critical to the plant’s financial success.

Lawrenceburg Power uses a triple-pressure cascading bypass system which helps in managing thermal imbalances between the gas turbines and heat-recovery steam generators in cycling scenarios. It includes high-pressure (HP), hot-reheat (HRH), and low-pressure (LP) bypass valves.

In this control scheme, the HP bypass valve maintains HP pressure to minimize thermal stresses on the drum. The HRH bypass, downstream of the reheater, maintains HRH header pressure, and reduces steam pressure/temperature to the condenser. Finally, the LP bypass valve maintains LP drum pressure and protects the condenser by reducing LP steam pressure/temperature to an acceptable exhaust condition.

The pneumatic actuators supplied with the turbine bypass valves were problematic, sometimes even failing to operate on a trip. Plant personnel noted that some of the actuators had multiple volume boosters and the oscillations were “ridiculous.” Before the unit was able to settle out, the control system was already calling for the valves to move to a new position. Think of the valves as being in perpetual motion.

Reheat pressure oscillations caused by pneumatic-actuator stiction, overshoot, or dead time cause significant fluctuations in HRH header pressure. Because of the sluggish performance with the TBS blending the lead and lag units it regularly took 3.5 hours for a warm startup.

After reviewing alternative actuators, staff decided to move away from pneumatic actuation in favor of REXA self-contained hydraulic operators. Personnel originally were skeptical about moving to a hydraulic medium because of issues experienced with oil cleanliness in the past, but they liked the compact/sealed design of the REXA product and were sold by the fact that there were no filters and no requirements for oil maintenance. The new actuators were installed on the existing valves as a drop-in-place solution. Performance improvement was noticed within minutes after the first startup.

Lawrenceburg effectively reduced its blending time by 80 minutes for a warm start. The blending scenario occurs between five and 50 days annually (or greater depending on the market), reducing fuel consumption and increasing operating time. Better control of steam pressures and temperatures also promote longer life for the HRSGs.

Trip events associated with the turbine bypass system, common with the original pneumatic actuators, have been eliminated completely. The new actuators operate with zero overshoot or hysteresis, and their response is virtually instantaneous after initiation of the command signal. An added benefit is extended trim life in all turbine bypass valves because the actuator is now driving the plug to the correct seated position.

Geodesic domes over clarifiers minimize contaminant ingress, evaporation losses

Chemicals was one of the biggest expenses for Lawrenceburg’s water treatment plant, with purchase and delivery costs running into the hundreds of thousands of dollars annually.

Another big expense was related to the failure of bearings for the plant’s clarifier rakes, which occurred several times. When a bearing failed, Lawrenceburg would curtail power production, thus reducing revenue. Plus, bearing replacement, which could take several days, was expensive considering the man-hours involved, cost of the new bearing, the time to drain the clarifier and remove the sediment, the cost of renting a crane, etc.

Disassembly of one of the failed rake bearings revealed that the failure was caused by water and contaminant ingress, not over- or under-greasing as might be expected. The clarifier design allowed rainwater to collect in the bearing area with no means of escape. A historical review of other equipment in the immediate area revealed that there have been repeated repairs in the past because of environmental factors.

In their review of the water treatment plant, staff discovered there was a huge loss of sodium hypochlorite (NaClO) from the clarifiers because of evaporation.

Installing geodesic domes over the clarifiers was a promising way considered by staff to reduce evaporation caused by the sun and wind. Plant personnel worked closely with manufacturer Ultraflote LLC’s engineers and agreed on a dome design suitable for Lawrenceburg.

Bottom-line improvement: The domes have reduced the annual consumption of sodium hypochlorite by 40%, saving tens of thousands of dollars. The domes also have eliminated the loss of generation caused by premature failures of the rake bearings and surrounding equipment.

Lawrenceburg Power LLC, owned by Lightstone Generation and operated by Consolidated Asset Management Services (CAMS), is an 1186-MW facility in Lawrenceburg, Ind, equipped with two 2 × 1 combined cycles. Plant manager is Mark Johnson.