Safety database developed in-house effectively tracks, validates contractors

Best Practices Award

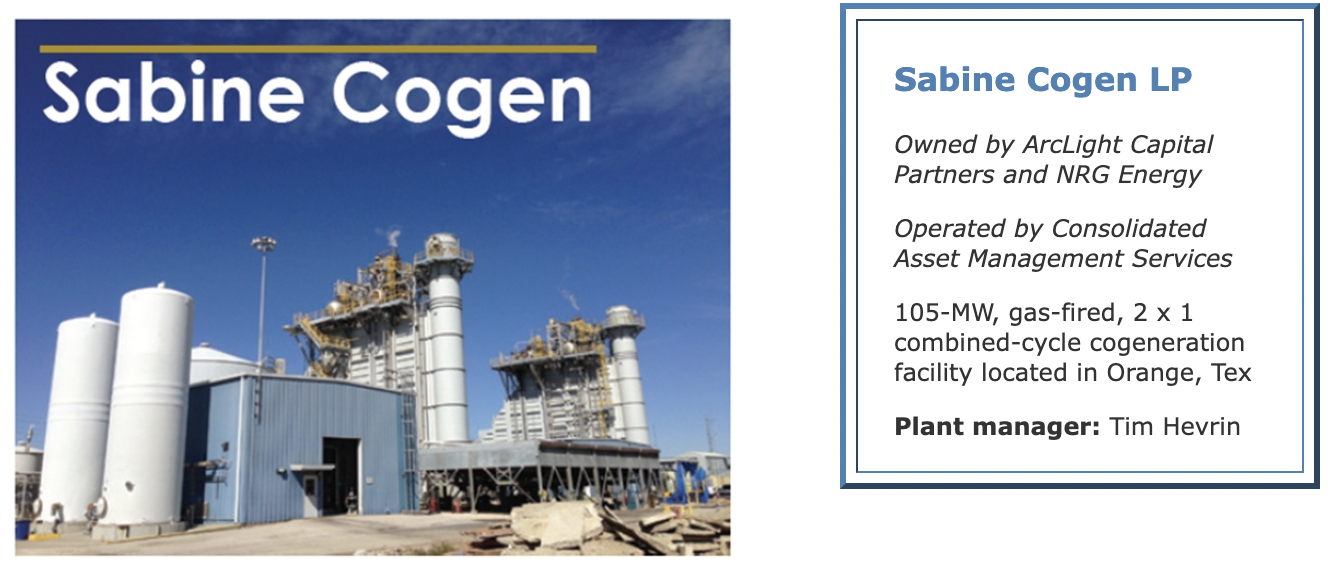

Challenge. Sabine Cogen, operating commercially since January 2000, is a 2 x 1 combined-cycle cogeneration plant providing electricity to the grid and to a nearby rubber processing facility. The facility burns natural gas and has an equipment rating of 105 MW. The site has nine full-time employees, plus operators on loan from the neighboring steam host.

Outside contractors are needed to assist in completion of day-to-day repairs, maintenance, and major maintenance activities. All outside contractors are subject to the facility’s insurance requirements and must receive safety orientation prior to commencing work onsite.

Historically, in an attempt to track required contractor insurance documentation, the site maintained a spreadsheet containing contractor names and insurance expiration dates. Periodically, the expiration dates were sorted and letters requesting updated insurance certificates were then manually issued. This system was not successful in that insurance certificates were expiring prior to letters being issued, and some contractors were found to be working onsite without proof of current insurance on file. All staff members could not readily access the spreadsheet.

Further, the system did not pre-emptively alert staff members of when insurance certificates were to expire or whether or not the contractor being called upon had an insurance certificate on file at all. Gaps in the previous system made the site vulnerable to having contractors performing work on site without required insurance coverage and created the labor-intensive tasks of manually tracking dates and issuing request letters.

In addition, outside contractors are required to watch a site-specific, safety orientation video initially and subsequently on an annual basis. Although a written registry was maintained and dated hardhat stickers were distributed, the site was unable to efficiently track which contractors had received the training and the annual training expiration dates.

Solution. To address the challenge of verifying current contractor insurance, a database was developed in-house to track certificate expiration dates. The database was developed using Microsoft Access with one table to store company data. Company names and insurance information can be easily searched, entered, and updated because of the user-friendly format of the database.

Data validation and input masks were used to ensure the integrity of any entered information. All staff members now have access to the centrally located database. A query was programmed within the database to easily identify company records with expired insurance certificates.

Additionally, a report was created, linked to the expiration query, which automatically generates request letters. The report is run quarterly. Fields are auto-populated with company information and the request letters and associated address labels are automatically generated. The report includes companies with insurance certificates that have either expired or will expire within the next three months.

The site still faced the challenge of tracking individual contractor orientation. The database was revised to include a second table for individual contractor information. A one-to-many relationship was developed linking individual contractors to their corresponding company, and a safety orientation sign-in screen was created.The database enables the site to easily identify contractors with insurance certificates that will expire ahead of time and significantly reduces man-hours needed to send requests for updated information and to track expiration dates.

Upon initial arrival, the individual’s information is entered into the database, which includes name, employer, and the date of the initial safety orientation. The database automatically generates an expiration date as to when the individual’s training must be renewed.

As the contractor is entered into the system, the associated company is selected from a pull-down menu of the previously entered data used for tracking insurance certificates. A sub-form located on the sign-in screen displays whether or not the outside company has current insurance information on file; therefore, the site is able to verify individual orientation status and company insurance documentation simultaneously.

Additionally, from the “Company View” screen, a list of each individual contractor that has a record can be easily viewed in a data sheet. The database also has the capability of scanning and storing safety training credentials, such as for heavy-equipment operators, for each individual. Future plans for the database include adding a safety rating to the contractor information based on initial contractor evaluations.

Results. Overall the in-house design and development of the safety database has provided Sabine Cogen with a cost-effective and efficient means of recording and tracking key contractor safety information. The database has significantly reduced the man-hours previously required to manage the same information.

Results. Overall the in-house design and development of the safety database has provided Sabine Cogen with a cost-effective and efficient means of recording and tracking key contractor safety information. The database has significantly reduced the man-hours previously required to manage the same information.

Verifying that outside contractors have the required insurance in place contributes to the protection of both the site and the individual contractor in the event of a safety-related incident. Because of the central location of the database and the easy-to-use screens, all site employees can now verify that contractors receive initial and annual site-specific safety information prior to commencing work. Because the tracking methods were developed internally, the site has the luxury of continuously improving the safety database as the need arises.

Project participants:

Brandy Dabbs, field coordinator

Rachal Havens, EHS specialist

Monitoring CEMS gas bottle pressure ensures compliance

Challenge. The continuous emissions monitoring system is a requirement for air permits and environmental regulatory compliance. CEMS provides a means of quality assurance, monitoring, and reporting for the site’s air emissions data and aides in the prevention of upset emission events and air-permit deviations.

The Sabine Cogen facility uses EPA protocol mixed gases for a daily calibration test that allows its analyzers to be proven accurate while remaining online. With any bottle service such as this, the potential to develop leaks or to exhaust all bottle pressure is very high. With the depletion of one of the mixed-gas bottles, it would result in a notice of violation for missed calibrations which can be very costly if not managed properly because of consequent material loss, environmental violations, personnel callouts, and overtime charges.

Solution. Sabine Cogen is committed to implementing effective, cost-saving solutions while maintaining optimal operation. One such solution was accomplished by integrating pressure switches on each of the daily calibration protocol gases while in service. A pressure switch has been installed for each of the protocol gases in service and the switches have been set at 200 psig.

The switches are integrated into the facility DCS, which allows operations to be notified immediately if a low pressure occurs. This alerting system allows ample time to remove and replace protocol gas bottles and to recalibrate the CEMS system, which prevents CEMS downtime and potential air permit violations and allows repairs and bottle changes to occur during normally scheduled work hours.

Results. As a result of the new system, after-hours call-outs for CEMS bottle replacements have been eliminated. Sabine Cogen has realized a cost savings in materials, labor, and potential environmental fines as a result of the new bottle pressure monitoring system.

Project participants:

Scott Spillane

Tommy McLeod

Darrell Hypolite

Joe Vincent