This is the second segment of CCJ’s three-part report on PSM’s 2024 Asset Management Conference, conducted at the Westin Beach Resort in Fort Lauderdale, Fla, January 29-February 1. The first segment was published earlier this year, the third installment will appear in CCJ later this year.

The focus here is fourfold:

- FlameSheet™ keeps getting better.

- Benefits of additive manufacturing (AM) in the production of R1 vanes.

- Technical presentations by industry partners on (1) generator field rewinds, (2) impacts of GT upgrades on heat-recovery steam generators (HRSGs), (3) exhaust-frame mods and improvements.

- Shop tour at the Jupiter center of excellence.

AGT Services: Surge in generator field rewinds ahead

Those who live along the Gulf Coast know that they are likely to suffer through one or more hurricanes (and the accompanying storm surge) annually. You just never know how many there will be or how severe.

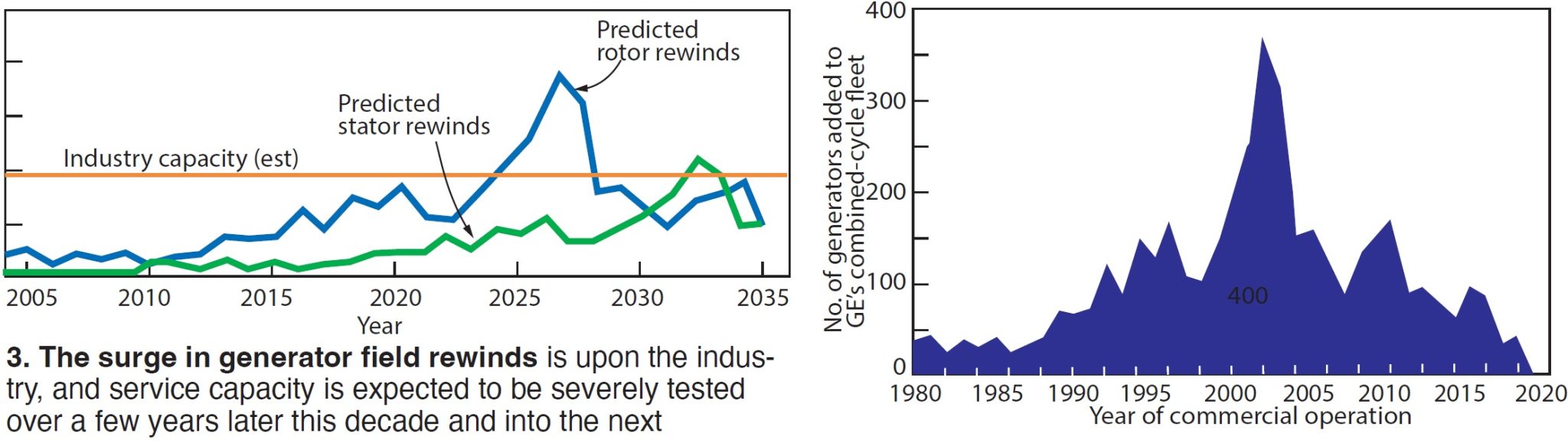

The surge of combined-cycle generator rewinds hurtling towards the industry is at least predictable. Just map the commercial operating date (COD) of the units in service to the 25- to 30-year life of the field windings, as Jamie Clark, AGT Services, did to open his presentation. What isn’t as predictable is the industry’s capacity to handle the surge (Fig 3).

Given that the peak wave will hit in 2027, only three years from now, the estimated industry capacity is woefully inadequate, and it can take years for a new service shop to tool up and train staff, ask yourself: Are my units properly positioned to weather this surge? If not, Clark’s slides, “Generator Outage Planning—Contingencies” offer a roadmap to get you started.

First, map out your plant/fleet, and organize generators by OEM, model, and vintage. Evaluate the fleet mix to determine “spares.” Identify long-lead-time components. Make sure you know what spares are typically available. For example, 7FH2 spare fields are common, but not 7A6, Aeropak, or WX/WY. Find out where and when you can get stator windings for your OEM/model. Consider carrying spare windings at the plant or fleet level. Map out diode/fuse supplies at each plant. Check to see if your service providers have high-voltage bushings, tubular leads, and other critical parts in stock.

Evaluate the baseline condition of your units. Consider minor inspections in lieu of field removal. If unit cycling has increased appreciably, shorten your outage intervals and factor in time on turning gear. Analyze your online monitoring data trends before any outage to get a snapshot of overall condition.

You’ll have to lock in contractors farther ahead of time than you may have been used to. Many units out there are well beyond their 25- to 30-year winding design life, and entering the period for a second, and even a third, field rewind.

Cycle times are increasing for critical parts and materials. Delivery of stator windings start at four to five weeks on an emergency basis. High-voltage bushings (HVB), brushless exciter fuses, and diodes are no longer routinely stocked by OEMs and fleet owner/operators.

Expect a minor generator outage (in-field, limited disassembly) to take one to three shifts, plus a shift for any brushless-exciter scope; a major outage (field rewind) to take three to five shifts plus a shift for the ElCid test and another shift for other special tests; and a “median” outage (robotic inspection) to take three to five shifts plus time for minor test/inspection scopes. These estimates do not include assembly/disassembly time.

Requests for quotes (RFQ) and purchase orders (PO) should be completed at least three months prior to outage start for a minor. For a major (field removed), RFQ and PO should be in place six months prior. Note that you can separate the mechanical scope from the generator contract. Plan on six months ahead for median-outage RFQs and POs to be in place. Plans for field rewinds and contractors should be in place six months before the outage begins, one year for stator rewinds.

Typical repair-project durations (again, not including assembly/disassembly) include:

- Seven to 14 days for stator rewedging and end-winding repairs.

- Seven to 10 days for retainer-ring-off inspection and minor repairs plus two to three days for high-speed balancing.

- 14-30 days for field rewinds and two to three days for high-speed balancing.

Any outage should be preceded by online testing and monitoring to contribute to the snapshot of overall unit condition, including on-line partial discharge (offline techniques also available), end-winding vibration trends, electromagnetic impulse (EMI) testing, and flux probe survey.

Clark’s slides offer a granular look at typical inspection and testing scopes, not reviewed here. However, one highlight is the availability of better robotic inspections (Fig 4). Clark cautions users to make sure your contractor’s robotics methods and tools have demonstrated experience with your specific OEM and model. For example, the smallest robotic inspection vehicle that is said to fit in the smaller-air-gap machines may still be limited because of the add-on components for the ElCid test and wedge mapping.

Often a borescope-aided visual inspection, requiring only a simple end cover removal, can be just as useful and often less expensive and faster. This permits full visual inspection of endwindings, stator main-lead connections (may need insulation stripped and replaced though), visual and even in-situ retainer-ring NDE. Plus, examination under retainer rings of turn insulation, slot armor, and main leads, and inspection of field body and stator (limited by borescope length).

Clark also emphasizes that most every OEM has bulletins out for brazed-joint connection inspections—including phase, series, stator main leads, and HVB. Because some connection endwinding designs severely limit access, radiography may be an option, especially since a pure visual exam or traditional NDE requires insulation removal and replacement.

However, challenges to radiography include access to joint locations, availability of resources, and outage coordination (may require cordoning off the entire turbine deck and best performed during the night shift). Also, if you discover one or more “indications,” how do you interpret the findings and what do you do about them?

Clark’s slide deck includes several photos of typical issues found during inspections, such as greasing at end wedges and connection ring ties, and various field winding conditions. Contact him at jclark@agtservices.com to request a copy.