This is the second segment of CCJ’s three-part report on PSM’s 2024 Asset Management Conference, conducted at the Westin Beach Resort in Fort Lauderdale, Fla, January 29-February 1. The first segment was published earlier this year, the third installment will appear in CCJ later this year.

The focus here is fourfold:

- FlameSheet™ keeps getting better.

- Benefits of additive manufacturing (AM) in the production of R1 vanes.

- Technical presentations by industry partners on (1) generator field rewinds, (2) impacts of GT upgrades on heat-recovery steam generators (HRSGs), (3) exhaust-frame mods and improvements.

- Shop tour at the Jupiter center of excellence.

Vogt: Don’t neglect the HRSG when evaluating GT upgrades

The gas turbine is part of a combined-cycle system and so the PSM Asset Manager’s Conference, part of the company’s global “Retrofit Revolution,” also included a presentation by Vogt Power International, “GT Upgrade/Low-Load Considerations for HRSG—Hydrogen Firing.” Most of the content mirrors the article elsewhere in the recent fracture article by Vignesh Bala, “Gas-Turbine Upgrades and their Impacts on HRSGs.”

The slides at the PSM AMC addressed non-thermal HRSG impacts (liners, baffles, flow distribution, catalyst, duct burner), as well as thermal impacts on pressure parts, tube/pipe velocities, drum/steam-water circulation system, attemperator, catalyst, safety relief valves, control valves, and I&C.

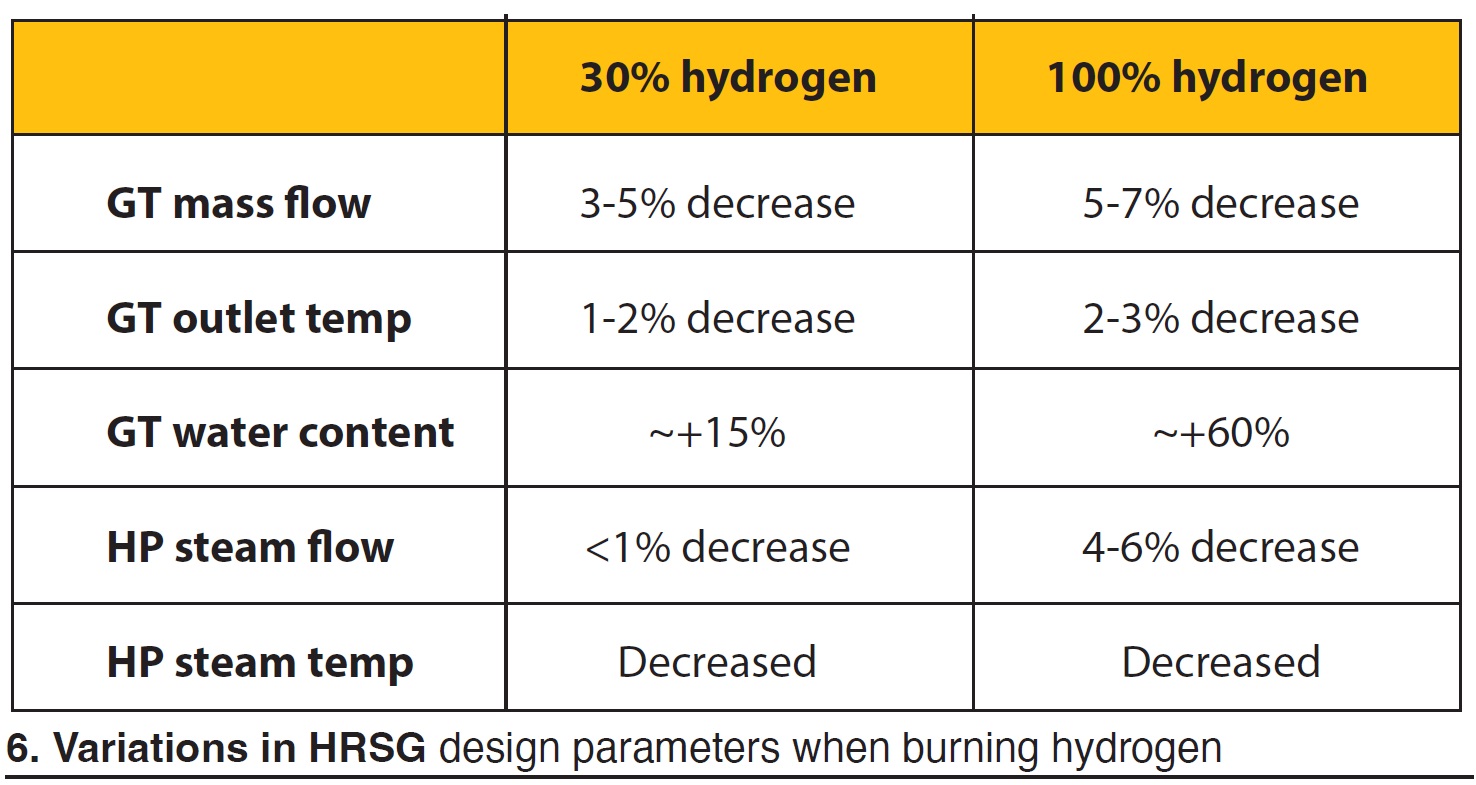

Of particular interest to CCJ readers may be that GT exhaust profiles can be quite different, depending on the design and configuration (Fig 5). And if you did already know this, at least the names are cute. There is the “donut” (peak velocities around 330 ft/sec), the “mountain” (peak velocity around 650 ft/sec), the “twin peaks” (peak velocity around 650 ft/sec), and the “bullet” (720 ft/sec). The exhaust profile should be verified by CFD analysis and accommodated, if necessary, through HRSG design modifications.

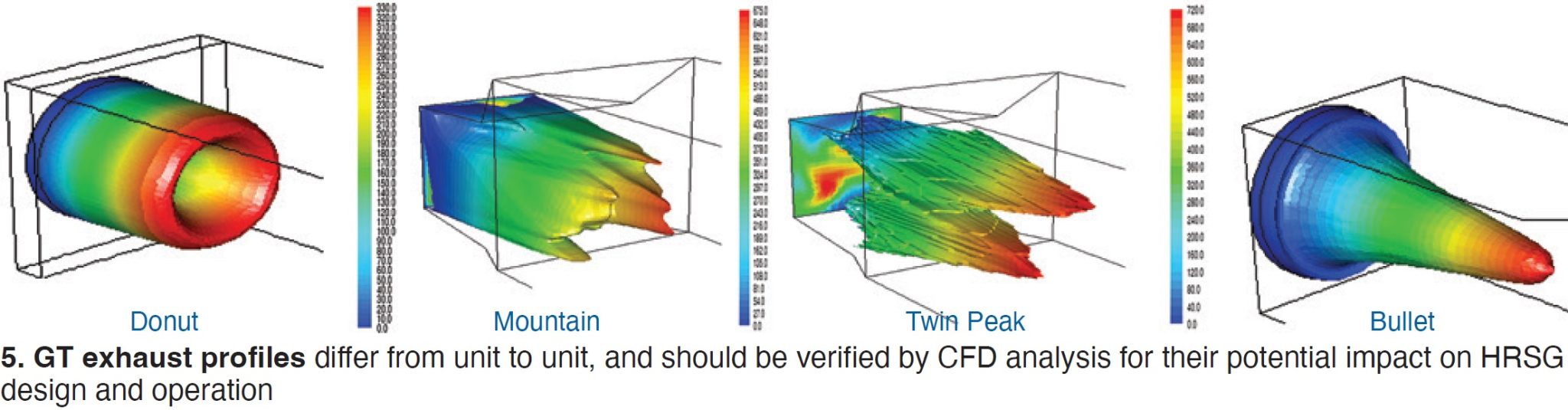

The last slide (Fig 6) is a handy guide to several important generic changes in HRSG design parameters resulting from 30% or 100% hydrogen firing. While the changes may seem modest on paper (the exception being GT-exhaust water content), an HRSG is a tightly designed subsystem and the impacts may be more than you think.