Cycle chemistry program for cycling plants

Best Practices Award

Challenge. A comprehensive chemistry program in a combined-cycle facility is key to avoiding long term issues and unexpected outages. The challenges for modern, air-cooled plants include high iron transport from the ACC process, flow-accelerated corrosion (FAC), and constant dynamic load changes and cycling which make it difficult to maintain chemistry within limits.

Solution. To address concerns on the overall effectiveness of its chemistry programs, PG&E engaged with industry experts at WorleyParsons Ltd, Sydney, Australia, to perform a steam-cycle performance assessment. It examined several areas of the plants’ programs including these:

- Chemistry program management.

- Statistical reconciliation.

- Optimizing ammonia/MEA feed to minimize FAC.

- Steam-cycle corrosion product.

- Online analyzer reliability.

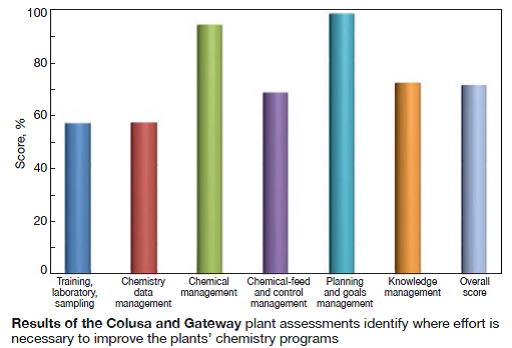

A WorleyParsons technical consultant worked with the O&M teams from both plants to develop assessments for each area. Program components are scored using a weighted scale so team members understand what the most important items are and what areas need the most focus and improvement (bar chart).

In addition to the assessment, plant staff implemented the following action items:

- Update of cycle-chemistry and chemistry program manuals.

- Initiated a quarterly sample-panel preventive maintenance program supported by the panel vendor.

- Upgrade of the plants’ chemistry logging systems to the latest web-based version.

- Purchase of new analytical equipment to better understand the condition of the plants’ closed- loop system chemistries.

Results. The steam-cycle performance assessment provided a detailed review of the overall chemistry program. This helped guide the plant staff to critical items for focus and improvement in the plants’ chemistry programs. This will reduce maintenance costs in the future as the programs, policies, and processes are optimized.

Several recommendations were made, and are being actively addressed, from the initial assessments to help improve the programs. For both facilities these included:

- Create chemistry training program.

- Assign training-program owner.

- Create analyzer calibration monitoring program.

- Perform annual safety audit for chemical feed systems.

- Create system survey.

- Start work on cycle chemistry manual.

- Require operator action for out-of-range readings.

- Logsheets: create limits for “record” parameters based on normal values observed.

- Water-quality diagrams: review and then make available to plant chemistry personnel.

- Logsheet limits: update limits as recommended in the consultant’s report.

- Consistent limits: update plants’ chemistry software, chemistry manual, and logsheets so that limits are consistent in all locations.

- Backup plant-chemistry databases at least monthly.

- Create knowledge-capture program.

- Create a monthly compliance report.

- Optimize ammonia/amine feed.

- Use specific conductivity to monitor and control condensate pH.

- Add deviation calculations to monitoring software for conductivity and pH analyzers.

- Check calibration of all pH and conductivity analyzers at least weekly using a calibrated handheld meter.

- Change cation resin when at least 10% active resin remains.

- Address issues with dissolved oxygen monitoring, monitor and record air in-leakage, perform dissolved oxygen wet tests, and find/fix leaks to maintain condensate dissolved oxygen content at less than 20 µg/l.

- Eliminate dissolved-iron tests; they provide little value.

- Perform suspended-iron tests daily on the condensate after chemical feed, and at least weekly on the LP, IP, and HP drums.

- Install online corrosion product transport monitoring of the condensate/feedwater after chemical feed and the LP, IP, and HP drums.

- Update target ranges in accordance with the statistical analysis.

Job safety analysis (JSA) for every job

Challenge. Performing a JSA for work activities is a major part of the planning process that could be overlooked or not viewed as part of the work scope. The Colusa and Gateway Generating Stations take a comprehensive approach to the JSA so it is an integral part of every job, every time, every day.

Solution. The organization’s JSA process protects employees and company assets by controlling the conditions under which maintenance, construction, and work activities are performed. It accomplishes this by requiring that the JSA be completed and approved prior to commencing work.

The JSA is the focal point through which the identification and mitigation of job safety concerns are handled. It requires the primary employee (the employee who performs or coordinates the work on the equipment or system that requires a JSA) to assess, and clearly identify and communicate potentially hazardous conditions to other employees, contractors, and transient workers prior to commencing non-routine plant operations or maintenance work. It also requires the primary employee to list the personal protective equipment (PPE) required, and to brief all personnel who will work on the job about the results of the hazard assessment.

The JSA is the focal point through which the identification and mitigation of job safety concerns are handled. It requires the primary employee (the employee who performs or coordinates the work on the equipment or system that requires a JSA) to assess, and clearly identify and communicate potentially hazardous conditions to other employees, contractors, and transient workers prior to commencing non-routine plant operations or maintenance work. It also requires the primary employee to list the personal protective equipment (PPE) required, and to brief all personnel who will work on the job about the results of the hazard assessment.

Completion of the JSA requires a comprehensive look at how the work is going to impact several areas including safety, environmental, and plant availability. All personnel associated with the work to be performed are included in the JSA and sign the form to indicate that they understand the hazards, risks and requirements of the specific job. Plus, the JSA form must be reviewed and approved by plant management/supervision prior to commencement of the proposed work. The worker or contractor working under the JSA takes a copy with him/her to the job site. That allows any member of the site staff to approach the work and instantly audit the job for adherence to the JSA.

In addition to the documentation, signage is posted to remind personnel of the need for a JSA and the short, limited list of items that can be done without a full JSA.

Results. The use of the JSA process ensures that a comprehensive and inclusive discussion occurs prior to starting a job. In many cases, personnel have discovered that a different approach is needed for the job, the job may be too risky to perform with the plant in service, or that the work will conflict with other jobs already planned or in progress. A discussion around safety always is the most critical part of the process.

In addition to the checklist of items, on the reverse side of the permit form is a layout of each facility with important information such as windsock location, emergency phone numbers, main radio channel and speed limits. This is of great benefit to contractor personnel who can carry this information with them while working at the site.

Contractor sponsor program

Challenge. How does the plant ensure contractors working onsite have a complete understanding of the work rules, PPE requirements, and hazards associated with the work they are about to perform? How does the plant ensure while a contractor is performing work it is following safe work practices? The answer: Provide contractors with a single point of contact for all issues that may arise while they are working on the plant site.

Solution. A PG&E sponsor is required for any work associated with an contractor performing work on equipment or systems within plant boundaries. The sponsor has the following safety/work process-related responsibilities:

- Clearly define and communicate the job scope.

- Act as the contractor’s field contact (sponsor).

- Perform a job safety analysis (JSA) to determine the hazard assessments for task-specific issues, identify PPE and other permit programs required to remove any potential hazards from those tasks, and document the foregoing on the safe work permit.

- Assess the risk of plant trips or de-rating that can occur as a result of performing the stated work.

- Assess the environmental risks associated with the proposed work.

- Review JSA results with the control room operator (CRO) in charge of issuing the safe work permit, and documents any recommendations made by the issuing control room operator on the safe work permit.

- Ensure all permits that may be needed are listed on the safe work permit prior to it being issued, and that the additional permits are obtained before beginning the actual tasks.

- Brief all PG&E employees and contractors assigned to the identified task on the hazards, PPE, additional permit requirements, and plant trip or de-rating assessment associated with that task and identify same on the safe work permit.

- Ensure employees and contractors sign and date the safe work permit to verify they have been briefed about the potential hazards, required PPE, and plant trip or de-rate risks.

- Ensure all corrective measures and actions listed on the safe work permit, such as PPE requirements, are available and properly used by employees during the performance of the tasks, and correct any deficiencies that may be found or reported by other employees.

- Ensure work is stopped when there is a change in scope beyond what is identified on the safe work permit. The CRO who issues the safe work permit, and the employees who are performing the work governed by the permit must be notified of any changes in work scope. A new safe work permit must be issued consistent with the new scope.

- Ensure that when the task is completed, or if the safe work permit must be closed, all required conditions, notifications, and documentation are completed properly and the permit is returned to the control room.

- Ensure that conditions for permit extension are met in the event that work continues beyond the specified permit expiration time prior to relinquishing the duty of primary to the next shift.

- Ensure employees and contractors clean the work area of all debris (welding rod, insulation, wire, etc), equipment is put away, and all affected employees have completed work prior to signing the “Work Complete” section of the permit.

Results. Colusa and Gateway Generating Stations have operated over 3000 days without an injury, contractor-initiated plant trip, or a contractor environmental issue. The plants have evolved to a safety culture where everyone looks out for everyone else: Contractors will stop work when safety issues arise and they will stop other contractors, and even PG&E employees, if they don’t feel comfortable with a situation. The culture and safety records at the plants are a clear indication the utilization of a contractor-sponsor program has been very successful.

Integrated outage work packages

Challenge. During outages, work is performed by different crafts on the same systems under the same lockout-tagout (LOTO) permit. The team wanted to create a system to help ensure information is easily available to personnel about all the work being performed on the LOTO they are signing onto.

Solution. The work packages were created to provide the employees with information of all the work and permits that are issued in one place. The packages consist of the following:

- Safety

+All required LOTO forms.

+P&ID and single-line electrical drawings with the isolation points identified.

+All notifications (work orders) to be performed under the LOTO.

+Hot-work permits, confined-space permits, and foreign-material exclusion (FME) zones.

- Outage schedule

+Work sponsors.

+Financial information for the workers to charge time and material.

- JSA

- Special conditions

Results. Benefits of the process are improved plant safety and communications during an outage. When an employee or contractor signs onto a LOTO he or she can review the other crafts/work being performed on the system they are assigned to work on. This is done by reviewing the JSAs, hot work permits, confined space, FME and P&IDs associated with the LOTO.

When forming the work packages, operators also look at the restoration process of the plant; they organize and assign the notifications to LOTOs in a way that allows them to efficiently and systematically restore the plant systems to service when the work is completed.

Project participants for all four entries:

Stephen G Royall, director of fossil and renewables

Ed Warner, senior plant manager

Ben Stanley, senior plant manager

Entire CGS and GGS plant staffs

Note that various forms, flow diagrams, and other materials submitted to the judges in support of the four entries from the Colusa and Gateway Generating Stations did not reproduce well and were omitted from this article.