Turbine-enclosure ventilation upgrade

Best Practices Award

Challenge. Walton County Power is a simple-cycle gas-fired peaking plant with three Siemens V84.3A2 engines. The gas turbines are insulated and housed in individual enclosures which have a history of overheating, resulting in turbine trips and equipment damage. Turbine instrumentation, I/O racks, and PLC circuit cards are inside the enclosure and all are susceptible to damage from overheating.

Ventilation equipment consists of roof-mounted exhaust fans and wall-mounted intake louvers controlled by a complex series of thermostats, relays, and louver interlocks. The ventilation system has multiple single-point failure modes and no communications link to the control system. This means that if one micro switch on a motor-operated louver does not work, exhaust fans will not start and the enclosure temperature will rise without the control room operator knowing.

Another limitation of the system is that it does not provide a means of override if needed. Example: If a limit switch fails to make contact, but a technician can see that the louver is indeed open, there is no way for that technician to put the fan in manual and start it.

The failure of the ventilation system has caused the plant to experience full-load trips, resulting in significant loss of generation. The high enclosure temperatures have melted components within control cabinets and caused I/O card failures, resulting in loss-of-control of critical equipment—such as lube-oil pumps. During one overheating event the turbine tripped and damage to the I/O control cards prevented the unit from going on turning gear.

Solution. Several modifications were made to improve the system and reduce the likelihood of overheating. These mods were implemented by plant staff and equipment costs were less than $300 per unit.

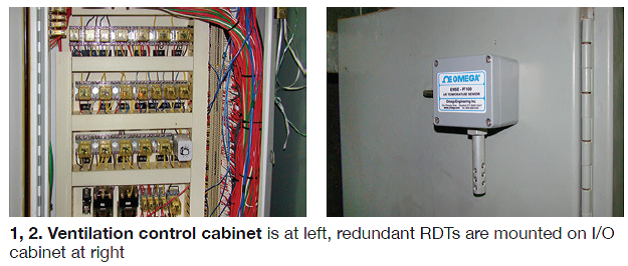

One of the first improvements was the installation of manual override toggle switches. The switches override the louver interlocks to allow immediate cooling of the compartment (Fig 1). They were mounted to the exterior of the ventilation control cabinet for easy access. Next the control cabinet incoming power fuse was replaced with a breaker. This provides the technician quick visual indication while troubleshooting.

Finally, the system was integrated with the plant control system. Redundant wall-mounted RTDs were installed on each side of the turbine enclosure on I/O cabinets (Fig 2) and the temperature output was added to the DCS. Control-system logic was written that provides high-temperature alarms and control-screen graphics of actual temperatures. The logic also provides for outputs to control fans and louvers in the future.

Results. No further unit trips have resulted from enclosure overheating. The CRO now has immediate indication of enclosure temperatures and can quickly dispatch site personnel to correct the situation.

Project participants: Wes McMillian, Charles Gibson, Christopher Harris, and Michael Gilbert.

Fuel-line venting improvement

Fuel-line venting improvement

Challenge. The site’s combustion turbines are outfitted with a dry-low-NOx combustion system. During summer operations in high humidity, condensate forms in a diffusion gas fuel line that is only used during startup and shutdown. Condensate is purged from the fuel line prior to shut down while the unit is above 100 MW. This is done to prevent the water from entering the combustion chamber and causing combustor dynamics and flame-out trips.

The original process for purging the line was to enter the turbine compartment and climb under the turbine to reach a bottom drain valve on the gas line and open it until water stopped exiting the pipe.

There were several safety concerns with this process: It required the technician to fit into a tight area under the turbine, high-pressure air was released near the operator, and communications with the control room was difficult because of the noise.

Solution. Realizing that a significant portion of the safety risk involved the area that had to be accessed by the operator to purge water from the line, the drain line was extended to outside of the enclosure.

Results. With the valve and drain line in a much more accessible area outside of the turbine enclosure the technicians are not exposed to the original safety hazards. It has also resulted in a more complete purge of the water from the fuel line reducing combustor dynamics and subsequent damage.

Project participants: James Goins, Wes McMillian, and Charles Gibson.

Walton County Power LLC

Owned by Southeast PowerGen LLC

Operated by Consolidated Asset Management Services

440-MW, gas fired, three-unit, simple-cycle peaking facility located in Monroe, Ga

Plant manager: Mike Spranger