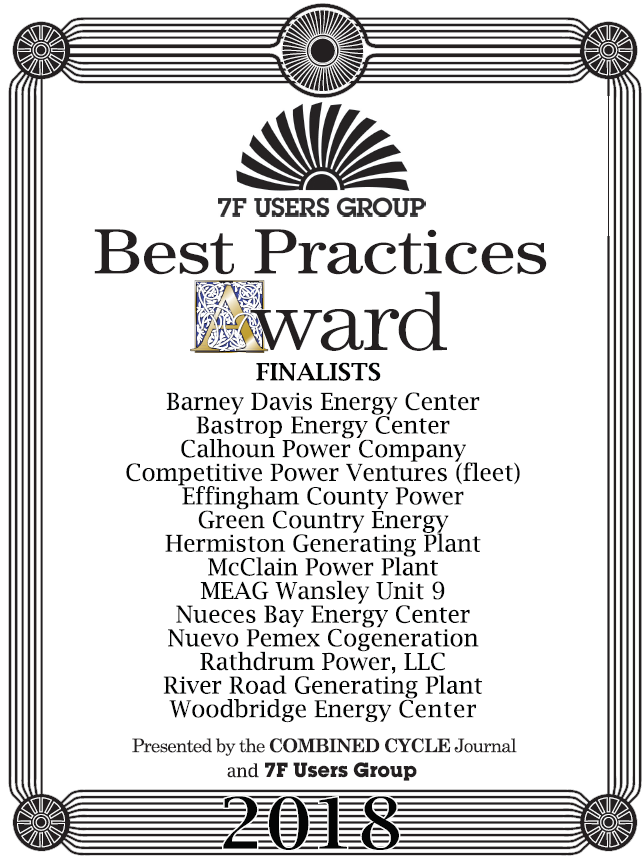

The 7F Users Group is a big supporter of CCJ’s Best Practices Awards program. For the last two years, owner/operators affiliated with this organization outpaced participants representing other frames and aeros. In 2018, fourteen 7F plants (chart) shared 26 best practices with their colleagues industry-wide. Recognize that the lion’s share of this material also pertains to most other frame engines and aeros.

This article summarizes the best practices submitted by Talen Energy’s Barney Davis and Nueces Bay Energy Centers, OGE Energy Corp’s McClain Power Plant, Calhoun Power Co, and Woodbridge Energy Center. The last facility is owned by CPV Shore LLC and operated by CAMS. Details will follow in CCJ’s 4Q/2018 print edition.

Best practices from Bastrop Energy Center, MEAG Wansley Unit 9, Nuevo Pemex Cogeneration, and Rathdrum Power LLC will be included in the next issue of CCJ ONsite. All of these plants are operated by NAES Corp.

The 7F recipients of 2018 Best of the Best Awards were recognized previously:

Additionally, a special feature based on fleet experience of Competitive Power Ventures with special software to speed access to best practices and lessons learned incorporated work done by CPV’s 7F-powered St. Charles and Woodbridge Energy Centers.

The sharing of actionable information on gas-turbine O&M is ongoing in this user group via its vibrant forum, webinars, impromptu telephone and email exchanges among members, CCJ best practices, and, of course, the annual conference—the world’s largest gathering of 7F users. User registration opens in January for the 2019 conference, May 20-24, at the Renaissance Schaumburg (Ill) Convention Center Hotel. Sign up online when registration opens February 1 to take advantage of a special early-bird discount.

Barney Davis and Nueces Bay Energy Centers, Managing hydrogen trailer inventory

Talen Energy’s Barney Davis and Nueces Bay plants are located about 30 miles apart in Corpus Christi, Tex; each is equipped with a 2 × 1 combined cycle. The close proximity of the generating assets and their similar equipment promote joint resolution of operating challenges. The following illustrates this point.

Preparedness plan for a rapidly approaching hurricane specified a plant shutdown and purging of hydrogen from the gas- and steam-turbine generators. It was not possible to receive a fresh hydrogen supply trailer before the storm hit.

Among the unknowns facing station personnel:

-

- Hydrogen supplier was not sure when a new trailer could be delivered given expected infrastructure damage in the area.

- Uncertainty as to whether the generators could be refilled with hydrogen from gas remaining in the onsite trailer and operate until a replacement trailer was received.

The options:

-

- Refill only two of the three generators and run 1 × 1 to minimize hydrogen consumption and maximize operating time.

- Refill all three generators to maximize short-term operation and risk running out of hydrogen before a replacement trailer arrived onsite.

Staff realized the financial impact of its decision could be significant because the market was reacting to the aftermath of the storm and forced outages at other facilities in the ISO. Rigorous analysis was necessary.

Plant personnel knew the ideal gas law (PV=nRT) could be used to convert the difference between current hydrogen trailer pressure and the pressure at predicted exhaustion to an available SCF value. Plus, the OEM provides expected hydrogen leakage rates, as well as equations for performing leakage tests. Dividing the available SCF by the hydrogen leakage rates of the generators (performing leakage tests provides a more accurate result) gives the approximate amount of time gas will be available.

Using this approach, staff determined there was sufficient hydrogen available to re-gas all three generators and still have the inventory to operate until receipt of a new trailer. Benefit: Plant offered the market its full 2 × 1 capacity rather than the 1 × 1 alternative.

Woodbridge Energy Center, Relay-trip check and connectivity diagrams

Woodbridge Energy Center is registered as a Generator Owner (GO) and Generator Operator (GOP) with the North American Electric Reliability Corp (NERC) in the ReliabilityFirst (RF) region. Like many registered GO/GOPs, Woodbridge must comply with NERC Standard PRC-005 which requires the site to develop a Protection System Maintenance Program (PSMP).

In developing the PSMP for this newly constructed site it was evident from the beginning that supporting documentation for relay operation and CT/VT connectivity to the relay was difficult to follow because of the many drawings provided by suppliers and manufacturers, the number of relays and CT/VTs, and the many possible relay operating scenarios.

Without a relay engineering background, operators found it virtually impossible to understand how the protection system functioned and/or how the system was interconnected. The complexity of the system also made troubleshooting a relay operation very difficult.

To decipher the route dc circuitry takes for any given relay an operator must understand multiple manufacturer drawings and symbols before actually locating the equipment in the field. This is a time-consuming effort.

Example: If a gas turbine in baseload service trips and you look at the front panel of the generator protection relay and see the notation “Under-voltage,” presumably this is under-voltage at the generator terminals. But by the time you access the drawings from the multiple manufacturers involved, learn all the symbols, figure out where the equipment is located, dig into the relay coordination study, understand the relay flex logic, etc, the unit is offline and in a forced outage.

Plant management wanted operators to know how the protection system functions and to assist in troubleshooting. To achieve this goal it was necessary to start with the basics and put operators with diverse backgrounds “on the same page” with respect to NERC PRC-005 requirements. This involved bringing the drawings together to develop a language of symbols, names, and devices common in the industry and familiar to operators without having to look at a manufacturer’s drawing index which may have pages of symbols.

Once a common language was established for devices, so-called Functional Relay Trip Check (FRTC) diagrams were developed. With three units onsite, it was necessary to compile three unique diagrams, one specific to each generator, plus four specific diagrams for breakers in the switchyard because of the complexity of relay coordination.

A simple diagram for each relay shows the given relay with its potential functioning modes, a line denoting the dc circuitry connected in most cases to a lockout relay, and the trip coil for the breaker. Simple, intuitive symbols illustrate a complete path for each relay.

At a glance, an operator can review an FRTC diagram without having to pick up a single one-line or manufacturer’s drawing. He or she can find the aforementioned under-voltage relay on the sheet and follow simple lines on how and where this relay could trip the generator breaker.

Woodbridge has three lockout relays connected to one generator protection relay; not all trigger in any event. With this diagram personnel can verify trip positions of the lockouts, verify the pertinent data prior to coming offline and feel comfortable in determining a list of potential causes prior to resetting a relay. Previously, much of this work would have been delegated to an electrical testing or relay engineering contractor.

In an effort to provide additional visibility to the location where a relay is connected to sense voltage or current, staff developed a CT-VT Relay Connectivity diagram. As for the FRTC diagrams, personnel had to develop three unique diagrams, one specific to each generator, along with four specific diagrams for breakers in the switchyard because of wiring complexity. Staff can now reference this diagram, instead of, in some cases, up to 30 separate manufacturers’ drawings, to understand the complete dc circuity path.

On a single sheet of paper technicians and engineers can see how every CT and VT is connected to any given relay within the facility. Now to troubleshoot the aforementioned under-voltage relay, technicians are not wasting time guessing which CT/VT set the generator protection relay is connected to in order to troubleshoot relay operation and make an informed decision about the cause of the relay issue.

Troubleshooting may determine that a true under-voltage event occurred, or technicians might possibly find the junction box was not properly secured by the electrical testing contractors and water was getting inside and sending a false current.

The bottom line: Better-informed operators are motivated to troubleshoot relay operations. Time is not wasted on trying to understand relay engineering jargon and where to find information on drawings from multiple manufacturers.

GO-BOX promotes safety, consistent job performance

In every combined-cycle plant, operators develop and use documents intended to help workers complete routine and/or non-routine tasks. These documents may include O&M procedures, work authorizations, job-hazard analyses, and safety data sheets.

A few challenges have become apparent regarding the use of such documents including: the availability and convenience of such resources, the awareness of when to refer to a procedure or additional resource (such as a job-hazard analysis), new employees being unfamiliar with an infrequent maintenance activity and needing additional resources, and the elimination of tribal knowledge for completing tasks.

Woodbridge staff was challenged with identifying a way to make resources more readily available to workers in the plant. If you’ve spent any time in a state or national park, you’re probably familiar with outdoor literature boxes for trail maps and other helpful information. Staff’s idea was to purchase literature boxes and place them in convenient, highly visible locations where jobs are commonly completed.

This allows the plant to bring procedures and safety resources right to the worker, hence the name “GO-BOX.” Not only does the GO-BOX eliminate a barrier for seeking out a helpful resource, it makes employees aware that a specific procedure must be followed while working on a given piece of equipment, or additional personal protective equipment is required.

Bringing new employees up to speed on more than 65 O&M procedures at Woodbridge is a daunting task. While new personnel go through extensive training, it is unrealistic for them to retain all pertinent information right away and it is incumbent on management to ensure necessary resources are available to improve safety and efficiency.

The GO-BOX also combat’s reliance on tribal knowledge by providing specific plant procedures to personnel with the intention of improving consistency in how to perform specific tasks.

To date, staff has installed 10 GO-BOXES around Woodbridge in locations where potential hazards exist or specific procedures must be followed when performing certain tasks. Example: A GO-BOX was installed at the emergency muster point, located at the main access gate to the facility. This particular GO-BOX holds the emergency response plan, facility plot plan, facility contact list, and safety data sheets for the major chemicals onsite. Finally, while GO-BOXES are a good resource for plant personnel, they also increase the awareness of contractors and first responders to plant procedures and safe practices.

deltaP gages alert to fouling of motor air filters

Woodbridge Energy Center, constructed near the shoreline of New Jersey’s Raritan River, is surrounded on three sides by marshland. Immediately after COD in January 2015, staff began following manufacturers’ recommended maintenance procedures for all plant equipment.

The facility has two boiler feed-pumps for each HRSG. The recommended interval for cleaning the pumps’ motor air filters is semiannual. In spring 2016, one pump tripped on high winding temperature. Dirty filters were not suspected because they had been cleaned only a few weeks earlier.

But after troubleshooting the motor protection relay and confirming there were no failed RTDs, one of the motor filters was removed and found packed full of seed heads from the phragmite plants indigenous to the area. Filters for the three remaining pump motors then were inspected and also found packed fairly tightly with the same seed heads. Action taken: The maintenance interval was adjusted to account for seasonal variations in the amount of pollen, seed heads, etc, in the air.

Knowing that the differential pressure across the filters could be directly correlated to air flow through the filters, staff added pressure taps on both sides of each set of motor air filters and connected them to a differential-pressure gage. Today, when the deltaP is more than 0.5 in. H2O above the baseline value, the filters are pulled and cleaned.

Since installing the deltaP gages there have been no motor trips/alarms caused by high winding temperature. Additionally, the gages have saved man-hours because use of condition-based maintenance principles eliminates the need to remove filters simply for inspection purposes.

Comprehensive one-line diagrams facilitate training, troubleshooting

Woodbridge Energy Center was constructed by a single EPC contractor with multiple equipment suppliers, thereby creating various scope-breaks between pieces of equipment. Staff found that following the electrical one-line diagrams and mechanical P&IDs for each system was a daunting task. At each scope break there is a line break in the drawing which references another drawing, this process could occur three to four times within one system making the review of a single system very cumbersome.

When referencing electrical one-line diagrams, technicians would find it difficult to grasp how the 230-kV power generated or imported would be stepped down and distributed within the facility. Like most electrical drawings it would only show one voltage level , such as 230 kV; another drawing would show 18 kV, still another 5 kV, etc.

During times of de-energizing or training for “what if” scenarios it was difficult to understand how bringing down one side of a switchgear could affect a system of lower voltage level without having to scour multiple drawings.

When referencing mechanical P&IDs, the same issue exists and requires having to pour through multiple drawings to understand the system completely from beginning to end. A single system could have up to seven drawings. Plus, all device numbers are based on the individual P&ID drawing number, which meant that if you located a valve in the plant and referenced its ID number you would have to know seven ID numbers for what is actually the same system.

First step in resolving the issue described was to pull every as-built electrical drawing and verify its integrity. During this process, personnel found multiple drawings with many revision levels based on changes that occurred during construction; however, not all changes made it to the panels or switchgear as a real change or the panels/switchgear labels were not updated to reflect this information.

Once the accuracy of all drawings was confirmed, Powergen Publications Inc was engaged to aggregate all of this information into a single diagram. Starting from 230 kV, a single one-line diagram was created showing each breaker, disconnect, power panel, transformer, switch, etc, until the system was developed down to 120 V.

Every voltage is represented by a different color so when referencing a drawing you know at a glance which voltage level you’re working on. The diagram also incorporated 125 Vdc down to 24 Vdc, information that is invaluable when trying to keep critical protective systems available for service during various O&M scenarios.

The same idea was used to build out a mechanical system diagram from flange start to flange end.

The diagrams immediately raised the confidence level of staff in recognizing the effects of components being removed from service, both electrically and mechanically. They also contributed to efficiency and time savings when planning and hanging plant LOTOs, troubleshooting, and for training.

McClain Power Plant, CO2 risk mitigation

Each of the gas turbines for McClain’s 2 × 1 combined cycle has three zones monitored/protected continuously for fire. Most maintenance performed within any zone is done when the unit/equipment is offline and under LOTO, thereby eliminating CO2 or temperature exposure risk.

However, employees occasionally must enter the auxiliary lube oil and gas compartment zones to perform operational checks and do minor maintenance with the engine in service. During normal operating conditions, high space temperatures do not exist within these two areas.

Nevertheless, if a fire monitoring/control failure occurred and released CO2 while someone was inside a compartment the consequences could be dire. Most likely an employee would be able to exit the space given a 30-sec release delay and an audible/visual warning system—unless, of course, the person was incapacitated.

To assure personnel safety, key-activated maintenance switches were installed. They enable employees to manually disable the CO2 releasing capability, by individual zone, when performing assigned tasks. As a further safeguard, operating instructions were developed. They explain system operation and emphasize the importance of three-way communication for allowing employees to safely access CO2-protected zones for a short time while the plant is in service.

Calhoun Power Co, Turbine compartment safety platform

The OEM installed a ¼-in. metal baffle plate near the IGVs to help direct ventilation air to the turbine compartment, making it impossible to do maintenance in that area without stepping on the plate. However, the baffle plate was not designed to support weight. Plant staff redesigned it to serve both as a ventilation assist and safe work platform.

Install current transformers on 89ss/nd motor-operator circuits

The plant had experienced multiple 89 static-start and neutral-disconnect motor-operator failures because of misaligned or slipped linkages. Weekly reliability cycling of the switches involved taking motor-operator current readings with a digital voltmeter. This procedure offered some indication of predictive failure, but only on a weekly basis, and was prone to operator-induced error.

Plant technicians installed current transformers on the 120-Vac motor operator supply with 4-20-mA feedback to the Mark VI. This permitted trending of current draw in the PI system and captured data from all switch cycles—not just that from the weekly reliability checks. Another benefit: Indication of potential issues with feedback switches when current draw is present and a switch indicates open/closed during cycling.

Result: Starting failures attributed to motor operators were eliminated and planned maintenance outages could be taken to repair issues arising from high current draw or over/under run indications.