Welcome the 7HA Users Group into the pantheon of power-industry organizations seeking peer-to-peer interaction to solve problems expeditiously and provide a collective check on official OEM positions regarding fleet- and plant-level issues.

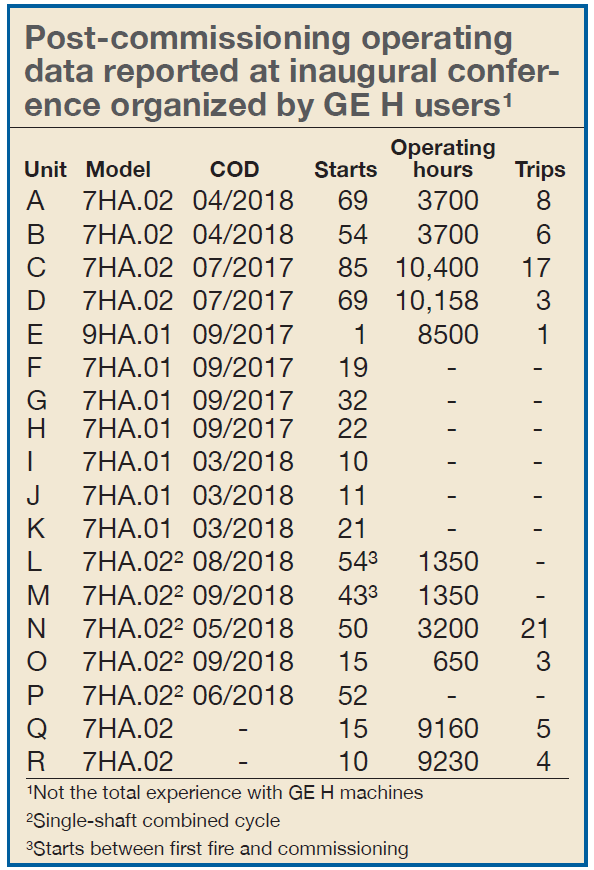

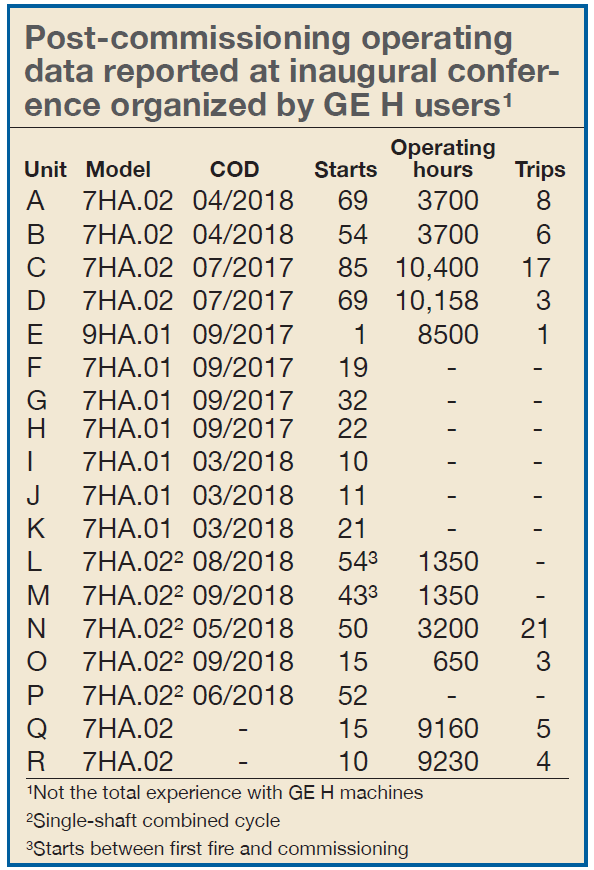

Representatives from well over a dozen facilities and five countries, responsible for 30+ machines, attended the inaugural 7HA Users Conference, in Fort Worth, Tex, Sept 12-13, 2018. The table illustrates machine operating stats as reported by the participating owner/operators. Obviously, it is early days for the technology with respect to commercial operations.

The scene was reminiscent of the early 1990s when the F-class technology emerged in commercial settings, dozens of units were sold worldwide, engines began operating before any appreciable operating experience had been gained with the fleet leaders, and before long, units were being air-lifted from around the world to have serious deficiencies addressed.

You can read about that experience in “Flaw in Design of Turbines Results in Massive Recall from Utilities All Over,” by William M Carley of the

Wall Street Journal, May 6, 1996.

We don’t preface this article this way to create ill will among users and OEMs, but to remind the community that the evolution of high-energy, highly engineered, cutting-edge power systems is rarely a smooth process. To get to today’s landscape of F-class machines humming around the world doing what is expected of them, for example, the industry had to get through a tumultuous early to mid-1990s period which deeply affected all five major large-frame OEMs at the time. Now there are three.

What follows is an exclusive industry report from the 7HA Users meeting. All technical issues are described generically out of respect for the extreme sensitivity owner/operators face managing the OEM relationship. GE was there in full force, though, with the meeting structured as first day devoted exclusively to owner/operators, and the second day to the OEM response, followed by a plant tour. CCJ was invited to attend only the part of the OEM session that had nothing to do with addressing issues.

The material, to the extent possible, is organized in priority of fleet issues and/or issues affecting multiple sites. Then a punch list is provided—issues experienced by one or two sites. Learning through open and transparent discussions among the folks who live and die with the equipment is the fastest route to commercial success with the technology.

Keep in mind that the 7H machine has established new industry records for power output, efficiency, emissions, and turndown flexibility. Some of these achievements are noted in the sidebar.

First-stage bucket failure

As if on cue to accentuate the importance of such conferences, the first speaker noted that one of its machines had, just days earlier, experienced a first-stage turbine (S1B) bucket failure after less than 10,000 operating hours. All four units (at two sites) being operated by this company were then shut down as a precaution.

Days after the conference, Reuters reported on September 20 that four GE HA-class machines in the US were shut down because of an “oxidation issue” and the company expected that all 51 machines shipped to date would be affected. The article also noted the fix, according to an OEM spokesperson, would require “minor adjustments.” Users at the meeting said GE had “acknowledged that this is a fleet-wide issue.

Others have reported that the oxidation affects a key alloy in the blade and shortens its life. GE, already dealing with existential corporate and Wall Street level complications, was dealt yet another blow by this event.

The bucket issue also has thrown into some turmoil the delivery schedule for machines to US customers, according many present at the conference. One, with a commercial operating date (COD) a few years out, said that the buckets destined for their machine, what were to be the first “Gen II” S1Bs, were now being diverted as replacements in the failed units. This action has postponed COD.

Users wondered aloud whether this “fix” would be the right one, since there is no commercial operating experience with Gen II hardware. The next opportunity to “look at them” in the first machine incorporating them, said the site representative, was not expected until a scheduled outage many months out.

Another operating site rep said the OEM was 9-10 months behind on spare parts and that they were “desperate for spare stage 1 blades,” and needed to “get through the fall on someone else’s blades.” A third site was expecting its S1B replacements in 2019. A fourth noted that they were getting a mix of Gen I and Gen II hardware. Finally, a site with several thousand hours on its HA.01 machines reported that the dampening pins for its first-stage buckets already had been replaced twice.

AFS failure

Some HA combustors feature axial fuel staging (AFS), of which a key component failed and caused damage at one site. The GT was operating at 298 MW when the failure occurred. It not only caused internal damage to the combustion system, but also breached a combustor can into the turbine compartment, triggering the fire protection system and tripping the unit.

There are 48 of these components on each machine with AFS. At the site experiencing the failure, 40 of these components were replaced. At least two other plants have had AFS components replaced.

As later elaborated on by a site representative, the DLN 2.6+ combustion system on such units consists of a fuel flow path referred to as “axial fuel staging” (AFS). Fuel enters the GT compartment and passes into a ring manifold and is delivered to each combustion chamber via “pig tails.” Fuel then is equally distributed to four ½-in. tubes attached on the outside of the “Unibody” (but internal to the combustor), and injected into the hot gas path through four nozzles.

The idea behind this flow path is to introduce fuel gas downstream of the flame zone and just upstream of the turbine first-stage nozzle. The fuel gas auto-ignites, increasing the energy available for the power turbine but with no increase in NOx emissions. This also allows for extended turndown while maintaining emissions compliance.

At the site with the AFS tube failure (during normal operation), a flashback occurred causing complete disintegration of two fuel nozzles, damage to the Unibody assembly within the combustor, and some splatter impinging on the turbine first-stage nozzles and buckets within the quadrant of the failed combustor.

There was also a breach of the combustor wall. Hot gases entered the turbine compartment and triggered the fire-protection-system heat detectors, which also automatically initiated protective action of immediate unit trip. Data review revealed that approximately 45 minutes before unit trip there was an instant spike in NOx, exhaust spreads, and low-band combustion dynamics.

The root cause of the AFS tube failure is unknown at this time pending completion of the analysis effort by the OEM.

Vibration

One site with around 3700 operating hours on its HA.02 machines reported that they had been plagued with cold-start transient vibration and start-to-start vibration issues associated with bearing No. 3, which the OEM had recently acknowledged were fleet-wide issues. The presenter said that half a dozen other machines were experiencing similar problems.

The vibration levels increase over time, and are associated with thermal changes in the unit. Low-load operation makes it worse. The vibration is supposed to be below 5 mils, but at times has been indicated as high as 12 mils, and routinely is around 7. Perhaps the most aggravating thing is there is no real pattern to the deviations, other than they tend to be “stable” at baseload.

Numerous foundation checks by the OEM didn’t solve the problem, nor did attempting to correct the balance with strategically placed weights (“shots”). In fact, “placing the shots in the wrong places led to numerous fruitless iterations.” An hypothesis of coupling misalignment also has not proven out.

Excessive vibration leads to secondary issues, such as oil leakage at the deflector plate from one of the generator rotor bearings, terminal strips coming loose, and failures of exhaust-thermocouple attachments. “We are replacing many exhaust thermocouples,” one said. Another site experiencing similar vibration problems is testing a prototype thermocouple that may be more robust.

One site reported that they had changed out the seals on the leaking generator bearing, added a row of labyrinths, and made some other adjustments which appear to have corrected their problem.

Complex controls

Several attendees commented on the complexity of the H-class control system and the shortage of OEM control-system engineers familiar with the H machines. “Controls are really complicated,” one said, “whenever we do a logic change, GE doesn’t have enough controls engineers to support us.” Another worried that “the digital intelligence is not 100% developed” for these systems. A site experiencing only one trip blamed it on a fieldbus error in the control system and subsequently requested that the GT controls be hard-wired.

A third presenter complained that the original GT/G controls had no redundant vibration configuration and cautioned attendees to “be aware of the primary-frequency response logic for performance tests.” This site also had incorrect digital valve position (DVP) firmware settings resulting from miscommunication between the OEM and the sub-vendor. The presenter urged his colleagues to “be familiar with foundation Fieldbus and Profibus for controls as applicable to the Mark VIe GT control platform.”

Punch-list items

Those in the queue for their machines, and those considering ordering an H-class unit, will want to consider the following punch list of items discussed at the meeting. These issues have not risen to fleet level issues, or at least not yet, and some may be peculiar to one or two sites, placed in the general category of “teething” issues common to all new facilities, and may have shared responsibility with the EPC contractor.

Digital valve positioners. The same site referenced above with about 3000 operating hours reported failures of digital valve positioners, an “instantaneous event” that leads to a GT trip, while another site reported that temperature-control issues with the DVP led to three trips.

Water intrusion. Fan/blowers in the GT housing reduce heat levels but also create a differential pressure which sucks water in when it rains. A site in an arid climate didn’t experience this until the first time the area got a good soaking. These blowers are redundant and both need to be in service because they are critical to maintaining an internal temperature so that electrical and digital electronics don’t “burn up.” One plant lost a bearing in the motor of one of the fans and had to replace the entire motor.

Air-filter cleaning system. This system has 400 small valves. One plant experiencing leaking in a few of these valves decided to replace all of them. The communication-system bus which “talks” to all the individual valves failed.

Online washing. Several plants do this everyday and had to make modifications to “make sure the pump logic was properly integrated.” One user cautioned that the drains are sized for “zero margin,” and had to replace a few bad valves and fix loose flanges.

Water carryover. More than one plant has experienced water carryover from the evap cooler into the gas turbine.

Generator. One plant had a flashover event with the collector brushes. The original number of brushes was based on the nameplate rating, but the OEM recommended that they be reduced from 24 to 12. One user cautions that generator end windings have “required lots of money and work.” The OEM calls it “normal wear and tear,” according to one user, and that you have to be careful negotiating with the OEM because they will accuse you of “improper maintenance.”

ST/G bearing leak. A site with a single-shaft combined cycle reported that the No. 1 bearing in the low-pressure steam turbine/generator had sprung a “major leak” and the plant had to “limp through the summer.”

Miscellaneous heaters. The same site just above also reported “lots of workarounds” with the startup natural-gas auxiliary heat exchanger, the natural-gas performance heat exchanger, and the air inlet heating system (upstream of the inlet air filters), as well as “lots of issues with the air-cooled condenser.”

Cap effusion plate. A site overseas reported minor cracks were detected in the combustor-cap effusion plate following a borescope inspection after around 8500 operating hours.

Igniters. One plant experienced packing leakage and overheated igniter wiring on two machines, discovered during the first inspection. The presenter noted that an igniter had liberated at another site he was familiar with.

Lift-oil pumps. One site experienced failures with the pumps, found a breaker off of one lift-oil pump and another that wouldn’t start, and noted that “lube-oil skids are tightly designed, very compact.”

Wolf Hollow offers early glimpse into H-machine performance

Two of the biggest, bad-ass gas turbines currently operating in the US are proceeding through their paces at Exelon Generation’s 2 × 1 Wolf Hollow II facility, Granbury, Tex, southwest of Fort Worth. CCJ editors stopped in to visit with Plant Manager Jeff Klier last spring during a swing through the state.

The GE 7HA.02 machines, together with a D600 steam turbine/generator and two HRSGs (delivered under the new GE ownership of Alstom), anchor the 1160-MW powerplant. Wolf Hollow is the first-ever application of GE’s D600 side-exhaust steam turbine—a design that translates to less complexity and lower construction costs.

The facility’s most striking feature, according to Klier, is its cycling flexibility. The plant is expecting to turn down to 350 MW and to ramp up to 1160 at 80 MW per minute.

The site currently is working with the OEM to optimize performance around the facility’s

typical load points. Results of inspections to date, including removal of certain components at different intervals typical of early days with fleet-leader units, suggest critical parts will have the lifecycle durations anticipated.

After 6000 combined operating hours between the two gas turbines, Klier reported “no deal-breakers” on performance, which he says is impressive for fleet-leader machines. To date, equivalent forced outage rate (EFOR) issues tend to be exhibited in the ancillary systems, not the turbine itself and not the new-technology components.

Klier concluded the discussion by noting that “we’re making history here, with respect to the evolution of advanced GT technology, and based on our early experience, this machine has a very bright future.”

GE and Exelon are full partners at Wolf Hollow II. Exelon has a contractual services agreement for service and maintenance, and Exelon partnered with GE to apply the OEM’s Predix monitoring, diagnostics, and knowledge-management platform.

7HA.02 backgrounder

The gas turbines installed at Wolf Hollow II are GE’s largest and most-efficient 60-Hz engines. They were ordered in 2014 and began commercial operation in late 2016. Here are some bullet points from the OEM’s 7HA.02 highlight reel:

- Fuel-flexible design accommodates the use of a wide range of gaseous and liquid fuels—including high-ethane (shale) gas and LNG.

- Simplified dual-fuel system uses less water, eliminates recirculation, and uses an enhanced liquid purge for improved reliability and dependability.

- Simpler configuration and modular design saved more than 10,000 installation hours compared to the 7F.03 gas turbine. Reasons include 40% fewer field connections and welds, and a 98% reduction in field-installed valves.

- Quick-removal turbine roof, field-replaceable airfoils, and full borescope inspection coverage of all airfoils streamlines maintenance.

- Four-stage air-cooled turbine with single-crystal airfoils protected by advanced thermal-barrier coatings.

- Advanced compressor has 14 stages (three with variable stator vanes) and field-replaceable super-finished blades.

- Fuel-gas pressure requirements are as low as 435 psig.

- DLN 2.6+ combustor with axial fuel staging is proven through tens of thousands of starts and more than 2 million hours of operation.

- Fast 10-min ramp-up from start command to full load; turndown to 25% of the baseload rating within emissions compliance.

- An air-cooled generator is available to simplify installation and maintenance.

Welcome the 7HA Users Group into the pantheon of power-industry organizations seeking peer-to-peer interaction to solve problems expeditiously and provide a collective check on official OEM positions regarding fleet- and plant-level issues.

Representatives from well over a dozen facilities and five countries, responsible for 30+ machines, attended the inaugural 7HA Users Conference, in Fort Worth, Tex, Sept 12-13, 2018. The table illustrates machine operating stats as reported by the participating owner/operators. Obviously, it is early days for the technology with respect to commercial operations.

Welcome the 7HA Users Group into the pantheon of power-industry organizations seeking peer-to-peer interaction to solve problems expeditiously and provide a collective check on official OEM positions regarding fleet- and plant-level issues.

Representatives from well over a dozen facilities and five countries, responsible for 30+ machines, attended the inaugural 7HA Users Conference, in Fort Worth, Tex, Sept 12-13, 2018. The table illustrates machine operating stats as reported by the participating owner/operators. Obviously, it is early days for the technology with respect to commercial operations.