Solutions for coupling-bolt issues, 501F 4-way joint leaks, and casing tensioners

Steve Busalacchi opened the presentation by explaining how his company’s EZ Fit coupling bolts have eliminated the costly, time-consuming challenges presented by seizure-prone fitted coupling bolts during outages. He noted the downsides and risks of using conventional bolts for turbine/generator couplings and explained the principles of mechanical expansion bolts—what they are, how they work, and how they mitigate the problems associated with conventional bolts.

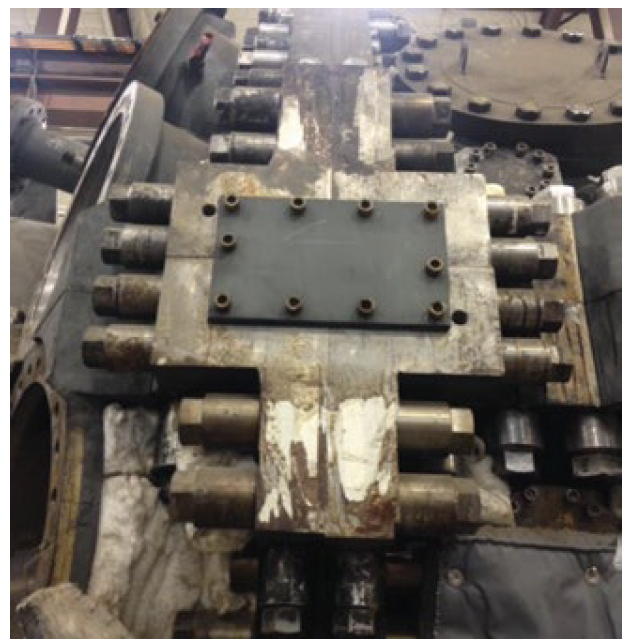

Features of the company’s multi-jackbolt (MJT) tensioners for both horizontal and vertical joints were discussed next, followed by an overview of the 501F 4-way joint leak solution (Fig 3). The latter eliminates forced outages caused by leak-by damage to instrumentation and assures a safer environment inside the turbine enclosure.

Installation of the 4-way joint solution takes the field-service crew performing the outage about three shifts to complete. Nord-Lock provides all necessary components and equipment as well as a qualified TFA.