Control-system retrofits at gas-turbine-based powerplants nationwide are driven by myriad issues. At the top is obsolescence: Many of these plants were installed during the “big wave” from 2000 through 2004 and the lifecycle of digital systems is far shorter than that of the physical equipment. Plus, many West Coast facilities have to adapt to the new dispatch requirements of the California Independent System Operator (CAISO). Finally, there are engine-specific issues not handled well by the original controls.

An unmanned peaking facility in central California faced issues in all three categories. The FT4 Twin Pac at the site was purchased and transferred from a Texas location in 2001. The original controls were tolerable for the old day-ahead bidding market, but not for CAISO’s recent 10-min dispatch requirement.

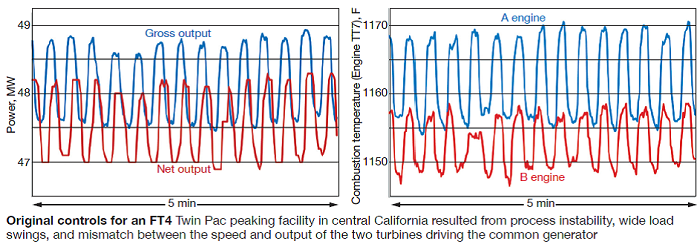

Problems included unreliable and unrepeatable starts, unstable synchronizing, difficulty balancing load between engines, slow response to load-change signals, hunting leading to resonance worries, and water injection control. Process instability (figure) is at the root of most of these issues.

Essence of the retrofit is the replacement of the OEM stationary power controller (SPC) with an Atlas-II™ central processing unit (CPU) from Woodward Inc. Although the MicroNet™ system is Woodward’s primary control product for gas turbines (GT), the Atlas-II, called a “simple” CPU, was considered by CSE Engineering Inc, engineer of record for the project, ideal for medium-size turbine situations. That it is 10% to 30% of the cost of MicroNet substantially supports that conclusion.

According to Mike Keehn, CSE senior control system engineer, the old Atlas CPU platform, dating back to 2002, exhibited a high processor failure rate in GT applications, but Woodward solved the problem by replacing the original Motorola chip with Intel.

A big advantage of Atlas-II over MicroNet is that reliability can be managed by keeping a spare CPU “on the shelf” which can be changed out in 30 minutes, while the other one goes back to Woodward for repair. In MicroNet, specific control cards have to be replaced at high cost.

Because the Atlas-II has been installed on LM2500, LM6000 (for dry low emissions applications), and other aeroderivative units, it has the necessary onboard speed and actuator inputs, Ethernet connections, etc. The Atlas-II CPU has the processing capacity to control the entire unit (with additional input/output, or I/O); however, here it is used only for fuel control and water injection.

As the site is unmanned, there is no control room per se but the unit is a computer so, while it can be field-located, it has to be in a well-controlled environment. CSE built a screen with pop-ups for the owner/operator displayed at its remote control and monitoring facility 45 miles away. The electricity off-taker has control over startup and shutdowns. An operator is dispatched to the site only if an alarm is triggered.

Among the bigger advantages is that the Atlas-II is programmable while the old SPC is an analog device, requiring many hardware modifications to adapt new control schemes.

Here’s how the upgrade solved specific problems:

Startup. This drove the project. The site experienced numerous in-cycle failures to start up, usually following light-off and associated with the need to synchronize both engines to one generator. For a peaking plant that gets paid to be “on call,” this was unacceptable and also involved penalties for non-performance in addition to non-payment for capacity. The original controls could meet the 10-min start (cold iron to full power), but did so at the ragged edge with potential mechanical impacts on the turbines.

Instability. The engines experienced unacceptable speed and output swings during the auto-synchronizing phase of startup of up to 1%, as well as during load changes. Analog controllers have difficulty balancing engine speed and load changes, which would lead to “hunting” and possible resonance issues. Minimizing these swings helped to shave a few minutes off the startup time.

Water injection. The old analog controls are more “fixed,” and often allowed over-injection of water into the combustor for NO? control, with possible flameout risk, and under-injection, which led to an emissions non-compliance risk during sudden load changes. The new controls can be programmed and tuned to the shape of the water-injection curve. Optimizing water usage is critical in a region with little raw water availability.

Enhanced control. The old system had no way to detect a flame-out, mostly because the SPC is not programmable. The new system includes basic flame-out protection based on exhaust temperature readings. It also is able to more precisely distribute the torque on the two engines based on the spread between the compressor discharge readings, a huge benefit during synchronization.

In general, the digital upgrade adds flexibility to operations and reduces risks from (1) instability in control, leading to mechanical cycling and premature metallurgical failures from fatigue effects, (2) failure to detect flame-out, leading to continued fuel injection, re-ignition, and explosion hazard, (3) failure to comply with emissions limits, and (4) failure to be online and at capacity when expected.

Startups are more consistent because the new controls allow operators to identify root causes of any trips. Performance of the downstream selective catalytic reduction (SCR) unit is more consistent because water injection is more precise.

Finally, a new Woodward GS-16 electronic fuel control valve replaced the existing Hamilton Standard servo position control valve, streamlining the control capability further. On initial installation, the valve experienced problems with voltage excursions, impacting the power supply, threatening unit shutdown during light off. Now, a couple of car batteries connected in series are used as a buffer. The lack of a bypass orifice for startup on the valve was handled with some iterative programming, again illustrating the flexibility of electronic digital control over the old analog systems. CCJ