Editor’s note: This article illustrates some of the benefits that accrue from upgrading ageing control systems. Dig deeper into the topic by participating in the upcoming webinar, “GT Mods and Upgrades: Take advantage of high-value generating opportunities,” Wednesday, February 10 at 2 p.m. Eastern. Presenters are Pat Begley and Ricky Morgan of TTS Energy Services.

The adage “age is only a number” pertains to equipment as well as to people, homes, and many other things. This article illustrates how gas turbines well cared for can provide good value far beyond their design lifetimes with modest investment.

Perhaps the best place to start this case history is with the Great Northeast Blackout of 1965. As the event title indicates, the Northeast went dark late in the afternoon of November 9 when a transmission line near Ontario, Canada, tripped, causing several other heavily loaded lines to fail—a domino effect.

Restoring power was a chore. As some involved in the process recall, the key to getting the New York metropolitan area up and running was a black-start Frame 5 on Long Island. Bootstrapping a grid start was the day’s challenge. The success of gas turbines in this endeavor made these machines the backstop of choice for grid support going forward.

Sales of simple-cycle gas turbines boomed in the late 1960s and early 1970s, with GE’s Frame 5 and Pratt & Whitney’s (P&W) FT4 leading the charge. Westinghouse Electric Corp (now Siemens Energy) had its W171, W191, and a few years later the W301, but those machines weren’t as popular in utility board rooms at that time.

Sales of simple-cycle gas turbines boomed in the late 1960s and early 1970s, with GE’s Frame 5 and Pratt & Whitney’s (P&W) FT4 leading the charge. Westinghouse Electric Corp (now Siemens Energy) had its W171, W191, and a few years later the W301, but those machines weren’t as popular in utility board rooms at that time.

The early gas turbines were conservatively designed and had “good bones,” assuring long life if properly operated and maintained (Fig 1). However, most have disappeared because larger and more-efficient machines make best sense in the majority of applications today. But some of these legacy units, uniquely positioned in the market, not only remain productive, but are worth investing in to extend their lifetimes beyond the half-century or so they have already served.

Kimura Power LLC, with generating plants in Ohio and Indiana, upgraded the control systems of its four- and five-decades-old gas turbines in 2016 primarily to improve their reliability in starting and in dual-fuel operation—an investment that continues to pay dividends. A bit of history: The Kimura Peaker Portfolio was a unit of AES Ohio Generation LLC, a wholly owned subsidiary of DPL Inc (Dayton Power & Light Co), until it was acquired by Rockland Capital LLC in spring 2018.

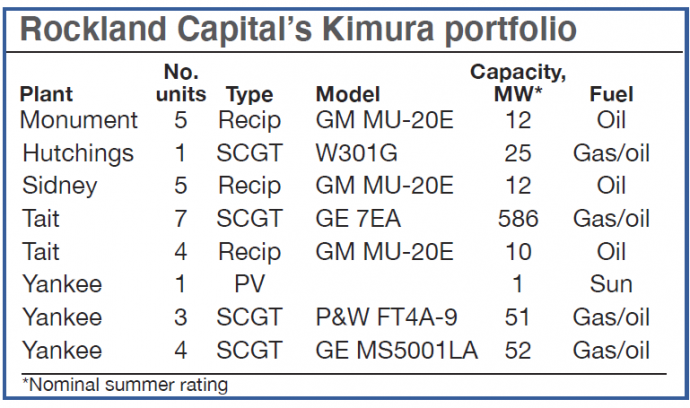

The upgrade projects described below involve Kimura’s Yankee FT4s and Frame 5s, and Hutchings W301—assets identified in the accompanying table. These peaking units serve the PJM capacity and black-start markets. They average about 70 starts annually, virtually all during June, July, August, and September. Typical summer-peak run time is 16 hours—early morning to about 9 p.m.

Kurt Lammrish and Mark Meade were among the decision-makers on the DPL team responsible for upgrading Kimura’s legacy peakers with 21st century controls. Design, installation, and commissioning of the new hardware and software, and training, were done by Orlando-based Turbine Technology Services Corp (TTS). Today, Lammrish is plant manager and Meade, who retired from DPL as peaker supervisor about when the Kimura assets were sold, serves the plants in a consulting capacity.

They told the editors the relay logic on the Frame 5s and the 301 had not been changed since those units were commissioned and that the Fives were equipped with Young & Franklin (Y&F) fuel regulators for engine control. Recall that the fuel regulator predated GE’s Speedtronic™ I, the OEM’s first electronic control and protection system for gas turbines. Think about the challenge associated with finding spare parts for those machines and then locating a technician to do the controls work needed.

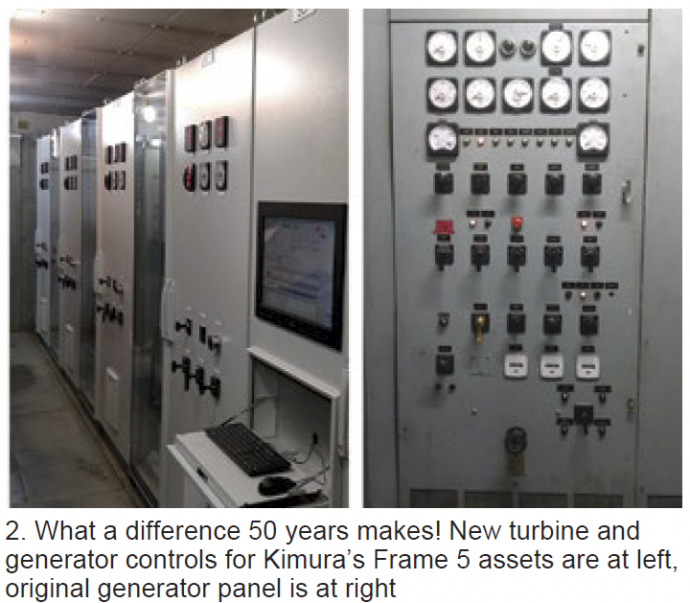

The Kimura upgrade. The original control systems for the legacy peakers, tough to troubleshoot, were replaced with TTS’s TMS-1000S turbine management system, built on Allen Bradley’s widely used ControlLogix® distributed-control platform (Fig 2). Not having to rely on the OEM for service cuts both outage time and cost when repairs, logic changes, etc, are needed.

The TMS-1000S uses the Ethernet-based Device Level Ring (DLR) architecture for processor I/O connections, thereby meeting NERC cybersecurity requirements. The provided switch assures a secure access point to the NERC recommended security perimeter by networked devices—such as remote HMI or engineering laptop.

TMS-1000S also relies on dedicated DeviceNet Networks for communications with such upgrades as the vibration monitor, electronic overspeed detection system hardware, and the electronic valve-position controller for GT gas-fuel control (get the details by attending the TTS webinar on Feb 10). DeviceNet uses the Common Industrial Protocol (CIP) to provide the control, configure, and data-collection capabilities for industrial devices.

Modbus TCP/IP delivers additional information from the TMS-1000G (generator) system, which includes generator protection relays, auto sync, power and energy meters, etc. Finally, the Distributed Network Protocol (DNP3), together with the power-quality and revenue meter, allows for remote viewing of output parameters such as megawatts, megavars, and generator breaker status.

Here’s an overview of key actions undertaken by TTS to bring the Kimura assets up to current requirements:

-

- Unit rewire. First, removed all existing wiring and terminals, cleaned all conduit, tray, and junction boxes, and replaced broken and damaged conduit fittings and terminal blocks. Next, installed new high-temperature cabling designed specifically for gas-turbine applications.

- Fuel systems. Control valves are core to the fuel system, which has experienced significant technological advancement in the last two decades. Removed pneumatic and electrohydraulic systems and replaced them with modern Woodward and Y&F electronic fuel valves, both highly reliable based on industry experience.

- On-base devices. Replaced transmitters and pressure switches and upgraded all instruments, thereby increasing reliability and making more information available to the control system and the operator. These upgrades allow the control system to generate more meaningful diagnostic alarms, thereby facilitating troubleshooting of problems.

- Liquid fuel system. Modified fuel pumps, replaced flow dividers, and upgraded other components to increase system reliability during starting, load changes, and fuel transfers.

- Multiple-unit HMI front end. TTS engineers believe upgrades to the human machine interface (HMI) offer huge benefits to users. Examples: Eliminates the need for an operator to enter pressures and temperatures in a log book, provides an indication as to why a unit tripped, etc.

- The modern HMI with the proper mix of useful/usable/readable graphics, alarm messaging, and real-time and historical trending provides operators the tools to properly manage the machine, monitor the unit and react as necessary to changing conditions, respond appropriately to alarms, and provide actionable information to others. An example of the last: Give maintenance teams the tools needed to identify and resolve problems quickly, minimizing downtime.

- Generator controls. The excitation-system upgrade involved removing the existing relay, potentiometer, static-based system and replacing it with a modern digital excitation control system. The protection-relay upgrade focused on the original electromagnetic relays. While reliable, they do not provide the historical information so valuable in troubleshooting. Modern digital protection relays provide the needed protection as well as actionable information. The excitation and protection systems are connected to the turbine control system, allowing key information to be displayed, trended, and logged by the HMI.

When all upgrades were completed—on time and within budget—the units were tested to base and peak loads on both fuels, and to maximum and minimum VArs. Plus, fuel transfers were executed successfully on load. Note that the controls for the Yankee and Hutchings peakers are local (at the individual units) with all remote-start capable and AGC (automatic generation control) operable. Control central is at the Tait facility, which has seven 7EAs and is manned 24 × 7.

The results. As to the all-important question, “How have the upgrades and the units performed over time,” Lammrish and Meade shared their experience thusly: Excellent! As of this writing, no outage or reliability issues have been attributed the TTS control system. In fact, Kimura will be ordering control-system spares for the first time in 2021—nearly five years after commissioning. There is no retirement plan for these units.

In closing, Lammrish and Meade shared their thoughts on TTS: A highly reliable, very capable partner always willing to go the extra mile to do the job correctly. A case in point was recreating controls drawings for the units, which involved an unexpected engineering effort.