Hydrogen purge remote activation helps keep employees safe

Hermiston Generating Plant

Owned by Perennial Power Holdings and Pacificorp. Operated by Hermiston Operations Co.

500-MW, gas-fired, 2 × 1 7FA-powered combined cycle located in Hermiston, Ore

Plant manager: Brad Knight

Challenge. Provide an automatic remote means to purge a hydrogen- cooled generator without dispatching employees to the area.

Many 1990s-era 7FH2 generators were equipped with an automatic purge system that activated when hydrogen purity at the seals dropped below a specified setpoint. However, the controls were located in the collector compartment and could not be safely accessed if a hydrogen leak in that compartment was suspected. In the event seal oil was lost it would be unsafe to approach the collector compartment to activate the purge. If the controls were left in maintenance for any reason there would be no way to activate the purge without endangering an employee.

Many 1990s-era 7FH2 generators were equipped with an automatic purge system that activated when hydrogen purity at the seals dropped below a specified setpoint. However, the controls were located in the collector compartment and could not be safely accessed if a hydrogen leak in that compartment was suspected. In the event seal oil was lost it would be unsafe to approach the collector compartment to activate the purge. If the controls were left in maintenance for any reason there would be no way to activate the purge without endangering an employee.

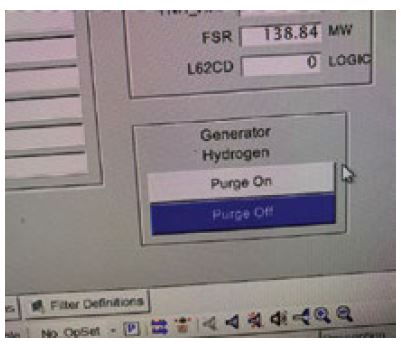

Solution. Since the automation was already in place along with solenoid- activated hydrogen shutoff valves, hydrogen vent valve, and CO2 admission valve, all that was needed was to move the controls to the Mark V. Employees of Hermiston and TTS Energy Services, Orlando, Fla, modified control wiring and re-routed it to the Mark V. Because of the significant safety and liability concerns associated with hydrogen, a controls consultant was engaged to modify the Mark V logic and create a purge button to activate the purge from the Mark V HMI (photo).

Results. Now control room operators can monitor hydrogen purity remotely and perform a preemptive purge in the event they lose seal oil, without putting employees or equipment at risk. The total cost of the project was less than $10,000.

Project participants: Scott Rose, Tim Key, Jason Gefre

Personal ownership leads to 25 years of no lost-time accidents

Challenge. Provide a working environment where all employees can go home safely each night, without sacrificing plant reliability.

Solution. Instill a culture with a sense of ownership for the plant and for the safety of the people around them. Hermiston Generating Plant as been owner-operated by Hermiston Operations Co since COD. The facility’s 50/50 co-owners, PacifiCorp and Perennial Power, are heavily invested in providing a safe working environment. HOC has been successful in inspiring employee ownership by doing the following:

-

- Investing $75,000 annually in employee safety and technical training.

- Developing safe work habits by hiring locally and training employees from the ground up.

- Handling significant decisions concerning safety, maintenance, operations, and accounting at the plant level.

- Spending time as a team—including team members’ families—at company-sponsored barbeques, safety events, and gatherings.

- Maintaining a highly active safety committee, managed and operated at the plant level.

- Empowering employees to stop any job, at any time, if they feel it is unsafe.

- Recognition from the owners through emails and awards.

- Investing in engineering controls, such as these:

- Automating the air-ejector skid to minimize ladder

- Relocating local instrumentation to ground

- Automating the hydrogen purge skid to be activated from the control

- Building safe working

Results. Hermiston Operations Co has achieved the following:

-

- Started its 25th year Nov 1, 2019 with no lost-time accidents.

- Was recognized as a SHARP graduate in 2005.

- Has a five-year average EFOR of 0.86%.

Project participants: All plant personnel