If the coronavirus pandemic has taught us one thing, having the ability to access the expert information needed to perform O&M tasks at the highest level without leaving the plant (or home) is vital. With good internet connections generally available at most powerplants, the challenge might be finding the information required. You likely have several preferred websites to search, ones that may have helped you in the past.

Is CCJ’s one of them? Our online library, keyword searchable on the homepage, can direct you to perhaps unimagined resources on the operation and maintenance of gas turbines and combined cycles. Included among these resources is our webinar library.

At home you might access a service such as Netflix for leisure viewing; at work search CCJ’s webinar library for guidance on how to identify and implement critical O&M solutions capable of helping you and your colleagues improve plant safety, availability, and performance.

To learn more about the library and its value for your facility, please skim the content summaries below of webinars added to the CCJ library in the last several months and use the QR codes to view one or two. No charge!

More webinars are scheduled for the weeks ahead; a lineup is available on the CCJ website. Included in this program is a collaborative, monthlong series of webinars presented by the 7F Users Group and vendors serving this critical fleet. Details and registration will be released soon. Bonus! If you miss the live sessions you can access the recorded versions at any time—just like Netflix.

Garret Haegelin’s goal is to help owner/operators of the industry’s most popular heavy-duty gas turbines—including 7Fs, 7EAs, 6Bs, and 501Fs—run their machines longer and more efficiently with cost-effective quality repairs and upgrades. The editors give his fast-moving 50+-slide presentation two-thumbs up both as a refresher for experienced plant personnel and as a primer for industry newcomers.

Haegelin discusses how to protect critical components against wear (fretting, abrasion, erosion), oxidation, corrosion, temperature, and stress, and explains repair options to avoid costly replacements when components are approaching the ends of their service lives.

Next, he shows how coatings (1) help prevent high-temperature oxidation in the turbine section, (2) mitigate thermal fatigue of vanes, (3) protect against hot corrosion caused by off-spec fuels, etc. A review of coating application technologies follows. The optimal method among HVOF, plasma, arc wire, cold spray, Haegelin says, depends on the part and type of coating, and he gave examples.

Case studies on (1) ways to make components more robust, (2) the benefits of repair versus replacement, (3) how to reduce degradation, and (4) approaches to extend service runs are particularly valuable for deck-plates personnel and should be considered by plant managers for lunch-and-learn sessions in the break room. All you have to do is access the presentation using the link provided here and share it with participants.

Photos of damage to transition pieces and combustion liners—such as oxidation attack, linear indications, etc—and the techniques Sulzer uses to increase the robustness of these parts kicks off the case-study portion of Haegelin’s presentation. Results of the shop effort are provided by way of photos showing indication-free welds after the service run following repairs, significantly reduced corrosion and oxidation attack, less degradation, etc.

Doug Nagy, who manages industrial steam- and gas-turbine component repairs at Liburdi Turbine Services, says the company’s LPM® technology saves users money by extending the lives of critical turbine parts. The high-strength metal-replacement process was developed for the repair of gas-turbine components over 30 years ago.

Doug Nagy, who manages industrial steam- and gas-turbine component repairs at Liburdi Turbine Services, says the company’s LPM® technology saves users money by extending the lives of critical turbine parts. The high-strength metal-replacement process was developed for the repair of gas-turbine components over 30 years ago.

Since that time, Nagy contends, Liburdi Powder Metallurgy has proven itself a useful and cost-effective process applicable to both repairs and new-component manufacture on polycrystal, directionally solidified (DS), and single-crystal superalloys.

As turbine owner/operators find their operating profiles shifting to starts-based maintenance cycles, the component life-limiting damage mechanisms have shifted from creep and coating consumption to thermal-fatigue cracking. Such cracking, Nagy says, is not well addressed by braze repairs, is tedious to rectify with weld repairs, and is very expensive to patch by couponing.

LPM technology, he continues, is a unique way to repair damage that is sufficiently ductile and has low distortion. The filler metal is a superalloy that can be varied in composition to provide specific properties; it can be used on cracked, crazed, and oxidized surfaces.

Capabilities include the following:

-

- Gaps of more than ½-in. wide can be filled without the distortion often identified with weld repairs.

- Surface areas of more than 10 in.² can be built up in thicknesses of up to 5 mils per layer.

- Heat treatments can be tailored to match the substrate.

- LMP repairs can be welded and re-repaired.

Alloys familiar to turbine owner/operators that have been repaired by LMP include GTD111, GTD222, FSX414, GTD741, and IN738.

The webinar explains the process and materials, how and why proper preparation is critical to success, and shows practical results from prior repairs.

CONCO. Practical application of tracer-gas leak detection and cleaning methods of air-cooled condensers, Gary Fischer, national sales manager, Conco Services Corp.

Every owner/operator of a plant with an air-cooled condenser (ACC) might benefit from listening to Gary Fischer on the value of an ongoing condition-assessment program and how the experts find performance-robbing leaks quickly. His presentation is fast-moving, easy for both new and experienced employees to understand, and answers the question, “Why do we not want to try doing this with plant personnel?”

Fischer begins with several slides on the importance of cleanliness, the sources of fouling, and how to remove external deposits. He dismisses the use of fire hoses (too much water, minimal cleaning effect) and high-pressure hand lances (damage to fins and galvanized surfaces) in short order and touts the value of automated cleaning (tight process control, uniform cleaning, no need for scaffolding).

For identifying the source of air in-leakage, Fischer says non-hazardous helium wins hands-down. Detection is quick and reliable for most leaks at 1 part in 10 million above background (5 ppm). Perspective: Sometimes you’re looking for a leak less than the size of a dime in a surface area equivalent to three or four football fields. Helium can help you find that.

Oftentimes leaks are not where an inexperienced person might believe they are. A leak can be outside the ACC proper and in the hogger or hogger exhaust, the gland-seal drain/trap, the crossover bellows, or at welds in retrofit projects.

Indicators of in-leakage are high backpressure, dissolved oxygen, and continuous hogger use. Don’t be surprised to find an air leak in a new unit, Fischer says. In one case, installers “simply forgot” a gasket on a jet isolation valve.

Tracer-gas leak detection, concludes Fischer, is a very cost-effective method for maintaining Rankine cycle efficiency where ACCs are installed.

Tracer-gas leak detection, concludes Fischer, is a very cost-effective method for maintaining Rankine cycle efficiency where ACCs are installed.

Vaughan Watson and Tim Shippy, both with decades of emissions-control experience, begin by urging listeners to “think beyond the catalyst to improve your plant’s emissions performance.” They review (1) areas of an SCR system susceptible to performance issues, (2) the importance of proper design and maintenance of ammonia injection grids (AIG) and how to avoid plugging, (3) the impacts of cycling and load changes on emissions performance and how to address them.

You will learn from in-depth case studies where AIG upgrades improved SCR performance; also, from the case study of a repowered combined-cycle plant to meet especially stringent emissions limits.

The presenters provide guidance on the reagent quality necessary for top performance, maintenance best practices, and SCR equipment and controls necessary to support fast-start/cycling operations. The use of in-situ tuning grids for optimizing AIG performance is included. They alleviate the need and expense of scaffolding, traverse testing, and reiterative adjustments.

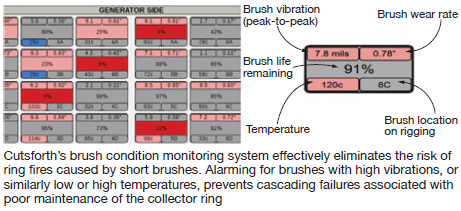

Cutsforth is an industry leader in the development and implementation of tools for generator condition monitoring—including brush condition, electromagnetic interference (EMI), and rotor flux. This two-part webinar updates personnel with generator responsibilities on the latest developments in diagnostic technologies and their commercial experience.

Subject Matter Expert Kent Smith of Kent Smith Consulting Services, the first chairman of the Generator Users Group opens the program with a definition of electromagnetic signature analysis (EMSA): The capture and analysis of both controlled and uncontrolled electromagnetic emissions absorbed by generators and other electrical equipment to determine if there are any uncontrolled sources of discharge being emitted from a given powerplant’s electrical equipment. The uncontrolled discharge signatures can be used to determine the electrical health of medium- to high-voltage equipment.

Electrical defects in generators that have been detected with EMSA include the following:

-

- Slot discharge resulting from the deterioration of side packing.

- Loose endwindings (broken ties), stator bars (loose wedging), and phase rings (circuit rings).

- Shaft oil/hydrogen seal rub.

Permanently installed EMSA detection equipment, developed in a collaboration between Duke Energy and National Instruments for implementation fleet-wide by the utility, replaces “portable,” bulky and high-cost data acquisition gear. The new instrumentation can capture and trend data hourly or more frequently and store it for analysis without wasting technician time in the field gathering of information.

The webinar illustrates time domain analysis of defect signatures, power spectrum trending and comparison, and signal strength comparison across 8000 frequencies.

Jahnke follows Smith with details on brush-condition, rotor-flux, and shaft-ground monitoring. The first allows plant personnel to perform maintenance based on actual brush condition rather than on calendar- or walkdown-based inspections.

Rotor flux analysis captures high-speed flux signals to identify shorted turns and their severity. Plus, flux waveforms and generator loads are archived for historical trend analysis. Installation of flux probes reportedly is relatively simple and not requiring an outage.

High-speed waveform ground monitoring is said to provide superior ability to analyze and assess shaft grounding conditions while also providing insight into broader generator conditions—such as these:

-

- Shaft rubbing.

- Shaft axial magnetization.

- Electrical discharges via bearing oil film.

- Vibrations.

- Isophase neutral faults.

Several failure and fault conditions described by screen shots illustrate the value of robust generator monitoring.

If you’re considering the automation of your generator’s degas process, this webinar was made to order. FPL’s Gary Griffin, in his fourth decade of serving the electric power industry, presents a case study that answers questions such as:

-

- Why automate the degas process?

- What safety elements can be achieved from the project?

- What technical requirements should you consider? This includes such considerations as logic location (DCS or local panel), size or presence of the CO2 vaporizer, time to vent/purge, fill time, generator pressure at CO2 fill, seal-oil pressure control during vent/fill, valve and tubing specifications, etc.

- What challenges might arise in project implementation?

E/One instrumentation and condition-monitoring tools available to assure generator safety, efficiency, and risk mitigation are summarized.

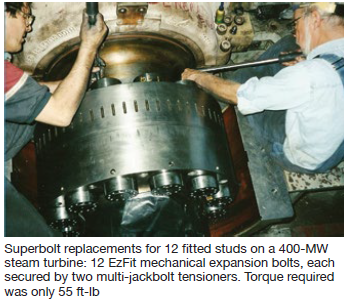

Nord-Lock. Solutions for turbine/generator coupling seize-up, Peter Miranda, director, business development, Nord-Lock Group.

Turbine pro Peter Miranda looks at the critical-path threat that occurs in turbine/generator coupling flanges when fitted bolts seize in their bores, plus other risks associated with using conventional coupling bolts. He explains the principles of mechanical expansion bolts—what they are, how they work, and how they alleviate the problems often experienced with conventional bolts. Case studies demonstrate how mechanical expansion bolts have been used successfully to eliminate the concerns with conventional bolts.

The photos and drawings (especially) used throughout the webinar enable you to quickly understand torque transmission by friction and shear drive, issues faced when using fitted bolts, and the benefits of expansion-bolt technology.

In case you missed this webinar in October 2019, rest assured. On April 21, 2020, CCJ and EthosEnergy will once again be onscreen to present an updated versions of last year’s webinar. Register here. Read on for some background.

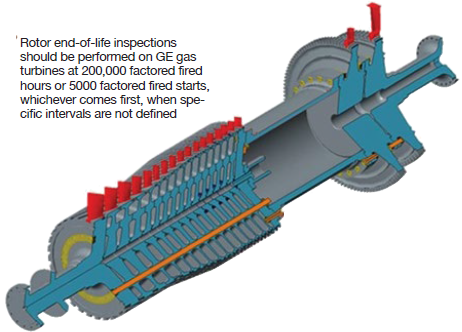

If your plant is equipped with a GE industrial gas turbine—Frame 3, 5, 6, 7 (A, B, C, E, EA, and/or F)—and mention of the OEM’s Technical Information Letter 1576 doesn’t make your ears perk up, you need to listen to this webinar. Even if you’ve heard about TIL-1576, it’s worth listening to for a refresher.

TIL-1576, released in 2007 and updated in 2011, identifies the equipment and personnel risks associated with operating gas-turbine rotors beyond 200,000 factored fired (FF) hours (144,000 for F-class units) or 5000 FF starts, whichever comes first, when specific intervals are not defined.

Kale Dreymala will take you through the inspection scope recommended by EthosEnergy Group (EEG) for turbine wheels, distance piece/spacers/stub shaft, and compressor wheels. If there are no findings, the rotor is reassembled with new bolts and your engine receives a certification for an additional 50,000 FFH (one time only).

If there are findings, the speaker says the OEM is likely to suggest buying a new rotor or possibly a replacement wheel or disc if that is the life-limiting part.

An affordable aftermarket solution suggested by EEG probably would be to obtain a used rotor with a documented history and refurbish it in the shop. The additional life certified (from 50,000 to 200,000 FFH) depends on an engineering review.

Dreymala will describe EEG’s capability for manufacture and qualification of new rotor components as might be required during the refurbishment process get the best balance between cost and additional life. Other rotor options also will also be presented during the webinar.