Green Country Energy is an 801-MW facility in Jenks, Okla, equipped with three 1 × 1 combined-cycle units. It is owned by J-Power USA and operated by NAES Corp. Plant manager is Danny Parish.

Complex underground water leak repairs

Challenge. Safety is one of Green Country Energy’s (GCE) core values. Occasionally, a job like the one described here, challenges the balance among safety, cost, and production.

The details: Operations identified a wet location between the steam-turbine building and the HRSG on Unit 3. This area is filled with gravel, so it was not too alarming at first. Some of the gravel was removed to see if we could find the general location of the leak. It seemed no matter where we looked, the leak appeared to be coming from that location.

Tests suggested the water was most likely coming from a breach in the circ-water piping located in that general area. P&IDs were reviewed and an excavation contractor was called to the site. Safety processes were reviewed and digging commenced. It appeared that the leak was somewhere on a line located directly under a major HRSG support platform. How to access the leak and repair the line in such a difficult location was a perplexing challenge.

Solution. Lone Star Hydrovac Co was hired to do the excavation. Its high-pressure water-jet system and high-vacuum truck made removal of the compacted gravel and fill a snap. The biggest attribute of this system was its inherent safety; no employee had to enter the area being excavated under the HRSG support pad. After excavating a small distance under the pad, Eden Structural Engineering installed a set of support pillars and jack stands to support the pad and the HRSG.

Then Lone Star removed the final material to reach the leaking pipe. The water was coming from a dime-size hole in a weld, probably caused by damage to the protective pipe coating during plant construction in 2002. The weld repair was made, the area backfilled, and the circ-water system returned to service.

Results. The leak was found and repaired quickly and effectively, and in a manner that was safe for all involved.

Project participants: All GCE O&M personnel were involved, with special recognition to Scott Helt and Thomas Hedge for leading the project.

Eliminating chemical-tote handling hazards

Challenge. A containment berm around Green Country’s chemical storage building complicated forklift entry. The nominal 4-in. sharp drop after crossing over the berm could possibly compromise safe entry. Staff re-engineered the entry, changing the sharp drop to a long gradual rise then gradual drop. Forklift operators liked the modification and management checked off one more safety improvement.

The saying “no good deed goes unpunished” applies here. Soon after the building entry was modified, a forklift operator penetrated one of the chemical totes with the forks. An RCA determined the employee was traveling too fast and the building was not arranged properly. Appropriate corrections were made.

Less than three months later, there was another forklift/tote puncture incident. Staff revisited the RCA process to identify the root cause of the new incident. The first thing noted was that after the berm was modified, there was an opportunity for the forklift to move into the building faster.

Also, it was apparent that the forks stuck out beyond the totes. Low visibility in the building increased the potential for future similar incidents. An exhaustive brainstorming session raised this question, “Why are we handling the same tote so many times?”

Solution. When the two forklift incidents occurred, a single chemical tote was being handled five or more times from delivery to empty. When a tote was delivered to the site, an employee would unload it from the delivery truck and place it in the chemical storage building. A day or so later, an operator would move the tote from the building, transfer about half of its contents into the bulk tank, and return it to the storage building. A week later, the tote would be retrieved and emptied into the bulk tank. A replacement then was ordered and the process described repeated.

The goal was to reduce tote handling to one single point-to-point process. Having a tote delivered directly from the truck to the location of use was the idea. This recommendation did not eliminate the hazard completely, but it mathematically reduced the likelihood of a recurrence, by 75% or more, and offered the benefit of eliminating the need to transfer chemicals.

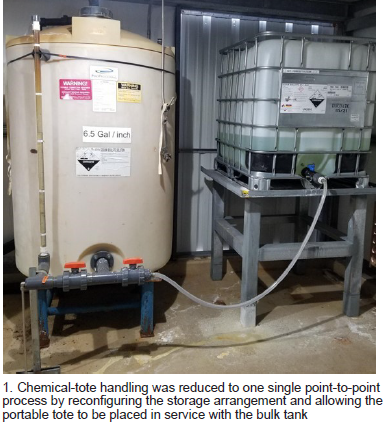

Several options could make this possible: (1) plant could purchase larger bulk tanks; (2) pay a premium for smaller bulk deliveries; (3) modify the chemical building to incorporate a two-tank system with a staggered level design that would allow the portable tote to be placed in service with the bulk tank (Fig 1).

The third option was selected. It works this way: As the level of chemical decreases, the portable tote becomes empty about seven to 10 days before the bulk tank runs out. This allows a replacement tote to be ordered and delivered directly to the staggered level design rack, thus creating a point-to-point delivery process.

Results. GCE personnel have implemented several safety-improvement processes—such as use of “spotters,” improved signage for specific tote locations, and guidelines on how close two totes can be placed in front of each other. Equally or more valuable, staff took time to review the plant’s cultural process for handling chemical totes.

By implementing a simple process change, totes are handled far less often, fewer people interact with the delivery process, and the plant saves about two to four man-hours weekly from eliminating tote transfers.

Project participants: All GCEO&M personnel, with special recognition to Scott Helt for leading the project.