With the power-generation sector shifting its fuel mix to an increased dependence on natural gas, the decreased downstream volume and unreliable gas pressure can wreak havoc on legacy power production facilities. It can be challenging for an ageing plant to remain a relevant, competitive, and reliable resource.

“If your gas supply system operates at a borderline pressure, investing in a new compression system will improve performance, reduce risk, and provide peace of mind,” Vincent Segale, a project engineering manager for SNC-Lavalin Constructors Inc, told the editors in a telephone interview. The successful integration of a new compression system into an existing plant is critical to maintaining—likely improving—the reliability and availability of that facility.

However, the original design probably didn’t account for this addition. Developing and managing a project of this nature requires resources and expertise that facilities may not be able to support internally. Segale should know. He has two decades of experience in powerplant design and detail engineering, much of that time spent on large combined cycles.

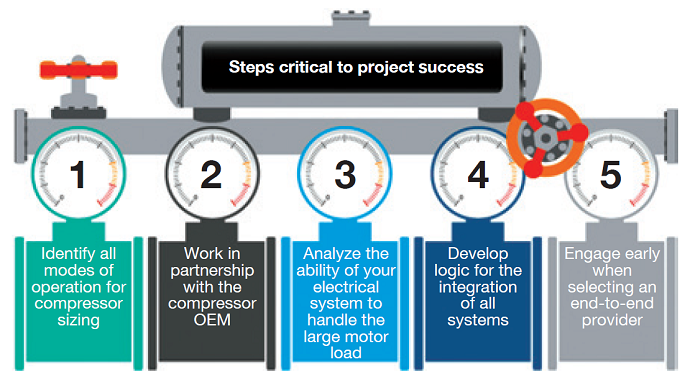

Segale’s involvement in fuel-gas compression systems typically extends from the proposal stage through commissioning and final testing. Based on his experience, which includes projects with reciprocating, centrifugal, and oil-injected screw compressors for both aero and frame gas turbines, there are five things critical to success that you should be aware of when preparing to add a fuel-gas compression system to an operating plant.

They are the following:

1. Identify all modes of plant operation to assure proper compressor sizing. Define the envelope of operation, including startup, turbine partial load, baseload, and turbine trip. Provide appropriate margins to safeguard that the compression system will support the plant for its envisioned lifecycle. Additional compressor sizing considerations related to pressure and flow capacity should be considered if gas-turbine upgrades, such as a gas path or flexibility improvements, could be in your future.

2. When researching the equipment, make sure your commercial agreement with the compressor original equipment manufacturer (OEM) works in partnership with you. If you have custom long-lead equipment, keep your OEM to the schedule. This is not a commodity purchase, so incorporating a proper milestone payment schedule and liquidated damages allows for the complete attention of the OEM with proper placement on its priority list.

Operating facilities have limited windows available during spring and fall outages when upgrade projects can be commissioned and proven out prior to returning to normal dispatch modes. If you’re not used to negotiating big commercial contracts, rely on your experienced end-to-end solutions provider to help you navigate relationships with suppliers and follow the nuances of the commercial terms and conditions to confirm delivery of technical information and equipment to support the schedule.

3. Analyze your existing in-plant electrical system for available capacity, short-circuit, arc flash, and voltage drop to accommodate the large compressor motor load. It has been known to stress existing systems. Many facilities may not have spare capacity in their medium-voltage motor control centers, necessitating a creative solution to accommodate the new load. Again, your end-to-end provider can help you analyze the situation and collaborate with you on solutions to add capacity and keep costs down.

4. Collaboratively develop controls descriptions and integrate logic for the new system with all key components. Be sure to consider integration of the gas-turbine OEM’s control requirements, balance of plant, DCS plant interface and communication, and compressor OEM’s standard PLC into a master control-logic description. Your end-to-end service provider has experience in system integration and can help you address all of the above early in project development to avoid a logistics nightmare during equipment commissioning.

5. Engage early: Select an end-to-end solutions provider that can provide the necessary support with engineering, construction management, and in-house commissioning expertise. This will ensure a fully integrated solution is delivered to support project goals and requirements. While reaching out to smaller, local consultants may be tempting, they often lack the specific powerplant experience and cradle-to-grave expertise. A fully integrated service provider can help eliminate potential gaps between design and construction, and commissioning.

Wrapping up the interview, Segale stressed that a significant plant upgrade, such as the addition of a fuel-gas compression system, requires in-depth knowledge of power generation facilities, structured execution methods, and careful coordination with plant operations for smooth integration into the existing facility infrastructure. “Through careful planning and investigation, understanding of equipment limitations, and finding the right engineering partner,” he said, “you’ll be prepared to make the case for successful system integration saving on rework, cost, and schedule.”