Vogt Power’s HRSG University came to Las Vegas June 27 for a full day of presentations and collaborative discussion conducted by Chief Thermal Engineer Kelly Flannery and two members of the boiler manufacturer’s aftermarket and field services team, Peter Allison and Deron Johnston. The informative program, presented without commercials beyond a 10-min review of who Vogt Power International is and what it does, appeared well-received by two dozen or more “locals” from NV Energy and other power producers in the area. The same program had been presented in Phoenix earlier in the week.

With budgets tight, and air travel and hotels at premium prices these days, Vogt saw an opportunity for its serious outreach program and was rewarded with support from power producers hungry for structured training on subject matter often overlooked in a time-constrained work environment. The meeting began with a two-hour session on HRSG design delivered clearly, quickly, and succinctly by Allison. It was a particularly valuable presentation for someone new to combined cycles and cogeneration plants powered by gas turbines and for those who needed a refresher.

Presentations on SCR catalyst and lessons learned in retrofit and upgrade activities to improve performance, and a primer on HRSG inspections, flanked a tutorial by Flannery on design ideas for improving the operating flexibility of conventional heat-recovery steam generators to meet emerging grid requirements. Flannery’s certainly was a timely topic considering the attention so-called fast-start plants with Benson-type once-through HP sections are now receiving.

The chief engineer began by reviewing why combined cycles should be designed, or retrofitted, to cycle and start and ramp fast: There’s money to be made providing grid ancillary services. Example: Rapid start/ramp to back up must-take renewables when the wind stops and clouds appear. Fast starts/fast ramps also reduce the total emissions during a start, cut startup costs, and enable the plant to achieve full-load revenues faster.

Flannery then suggested several things users might consider incorporating into their specifications to enable fast starts and ramps, including the following:

• HRSGs and condenser designed for 100% steam dump capability. Water-cooled condensers, he noted, are more conducive to fast starts than air-cooled condensers.

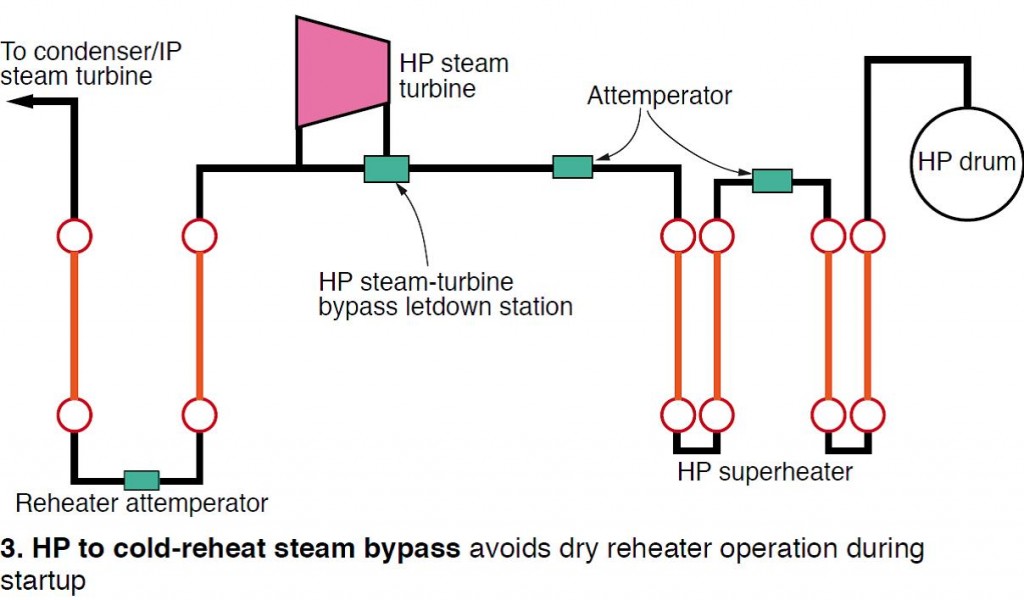

• Wet reheater. Flannery recommended putting steam into the reheater as soon as possible after the gas turbine is started. Running the reheater dry shortens its life, he said.

• Provide a final-stage attemperator to accommodate the steam-turbine roll. Some owner/operators view this as a risk. While it certainly is more risky than having no final-stage attemperator, the risk can be managed by good engineering and conservative design—that is, an adequate run of straight piping downstream of the attemperator, quality valves, effective drains, and good instrumentation.

• Effective design and tuning of the BOP control system.

• Online, real-time monitoring of HRSG life consumption.

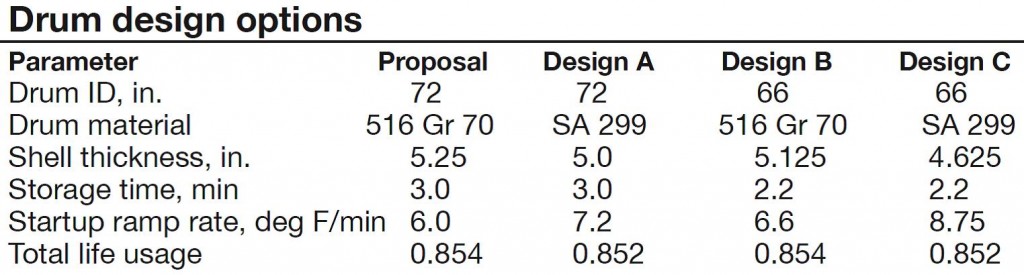

Flannery spent about 10 minutes on pressure-part design considerations to accommodate fast starts and cycling. He began with a review of the all-important HP drum, made of carbon steel, which is used for steam/water separation and to maintain adequate storage volume. The ability to reduce drum size (read shell thickness), he said, contributes to faster starts and ramps, as the table confirms. Today’s tools for finite element analysis help engineers design for minimum thermal soak time.

The table shows how drum design parameters impact the ramp rate of a typical F-class combined cycle. The standard offering described in the first column would be a 6-ft-diam drum made of 516 Gr 70 steel and having a shell thickness of 5.25 in. Storage time is the industry norm of 3 minutes, the allowable startup ramp rate 6 deg F/min.

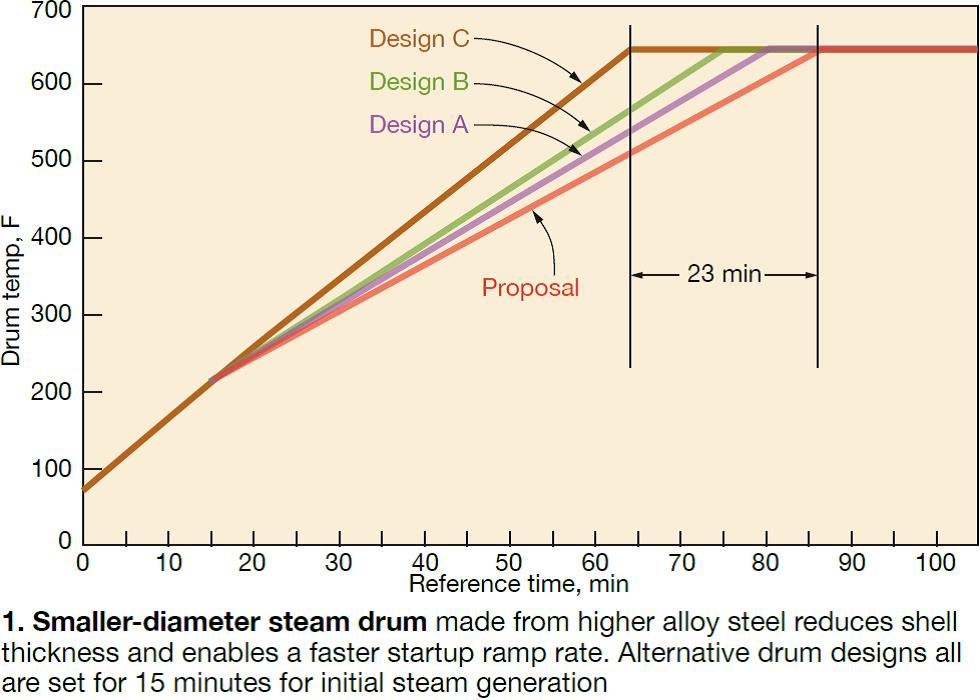

Fast forward to Design C: With a startup ramp rate of 8.75 deg F/min it can reach rated output faster than the other options. It employs a higher grade of steel for a relatively small financial penalty. SA 299 typically costs less than 5% more than the baseline 516 Gr 70. The smaller drum is made possible by taking exception to the 3-min storage rule, the speaker suggested. The rapid-response capability of modern control systems is said to allow the reduction in storage volume to 2.2 minutes, possibly less, without compromising plant reliability. Fig 1 illustrates the advantages of Design C well. It comes up to the desired drum temperature in 64 minutes, compared to 87 minutes for the reference case.

Looking ahead, Flannery sees other possible changes to standard design practices for drum-type units to enable cycling and faster starts. These include:

• Drums with still less storage capacity, perhaps as low as 1.25 minutes.

• Thicker nozzle connections than required by the ASME Boiler and Pressure Vessel Code, to increase service life.

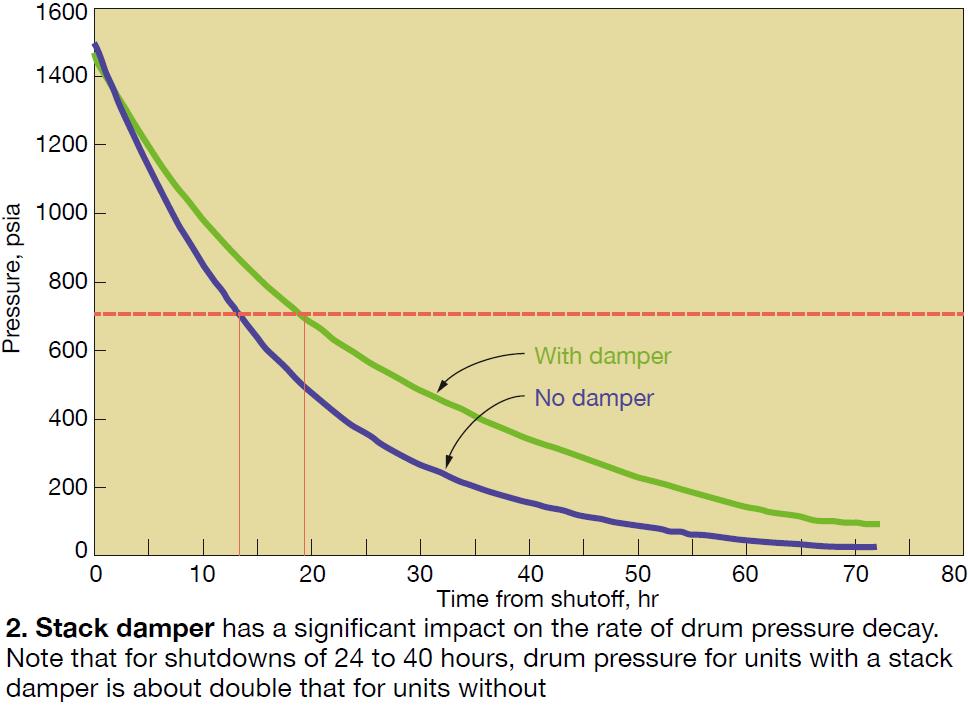

• A method for keeping the HP drum and HP evaporator warm during shutdowns, to avoid cold starts. A rule of thumb: A cold start consumes seven-fold more drum life than a warm start and the latter uses up four times more drum life than a hot start. Maintaining the drum at about 400F significantly increases its design life, the speaker said.

One way to keep the HRSG warm during shutdown periods is to install a stack damper and make sure no valves are leaking. The upper curve in Fig 2 shows drum pressure decay for a HRSG equipped with tight valves and a stack damper. Note that drum temperature is held at or above the recommended 400F through a weekend shutdown. Flannery also recommended insulating the stack to minimize condensation in the back end of the unit.

Fig 3 illustrates the wet-reheater arrangement mentioned earlier to extend the life of that tube bundle by avoiding dry operation during startups. For success, this scheme requires the condenser to handle full-load steam flow, which usually is not possible at an existing plant. For a new plant the condenser obviously can be sized appropriately.

Other design considerations to support cycling include these:

• Automated vents and drains and the use of condensate drain pots for positive verification that all condensate has been removed from the reheater and HP superheater. Recommendation: Install quarter-turn ball valves on all drains.

• Motorized blowdown valves for drum chemistry control.

• Leak-proof valves in attemperator systems to avoid piping damage from water impingement, to prevent water from entering the superheater panels, and to minimize pressure decay during shutdowns.

• Steam sparging to keep the boiler warm during shutdowns and assure proper freeze protection. Flannery suggested that owners get an auxiliary boiler into the plant environmental permit.

• Drum-wall thermocouples to provide the best information available for decision-making.

• Avoid complicated piping arrangements to accommodate expansion and contraction with minimum stress. ccj