Tube leaks are the leading cause of forced outages in coal-fired boilers and EPRI research suggests they also are the major cause of damage to multi-pressure combined-cycle plants. Carryover of water into tube bundles, dewpoint corrosion, offline corrosion, high-temperature oxidation, and metal fatigue from cycling—among other mechanisms—contribute to, or are the direct cause of, tube failures in heat-recovery steam generators.

Owner/operators work diligently to avoid forced outages: An unplanned outage at an inopportune time can put a serious dent in your plant’s bottom line. Until recently, finding tube leaks before they caused an outage was a hit or miss proposition. The acoustic monitoring solution presented elsewhere in this issue is capable of mitigating risk, but there’s more you might consider doing. Example: Conduct a health assessment of your HRSG’s pressure parts and welds. This has been discussed frequently in the CCJ as a way to identify cracking in steam-drum nozzle welds, to measure the wall thicknesses of components in areas prone to attack by flow-accelerated corrosion, etc.

The maintenance supervisor at a Mid-Atlantic 2 x 1 F-class combined cycle installed during the bubble, concerned about the number of cracked tube-to-header welds occurring at the bottom of his HRSG panels, took condition assessment to the next level. He had all lower tube-to-header welds in the three rows (total) of reheater and superheater tubes examined by technicians proficient in dye-penetrant, mag-particle, and x-ray techniques. Plus, he had sections of one reheater tube and one superheater tube removed for detailed laboratory analysis. A section of a third tube was removed and replaced in-kind because of damage.

As many plant managers have learned, work done constructing plants during the bubble often was careless. Improper hardness of P91 and the use of wrong materials in piping systems and for welding are two examples. In this case, crack indications were identified in 14 tube-to-header welds; the welds were ground out and joints rewelded.

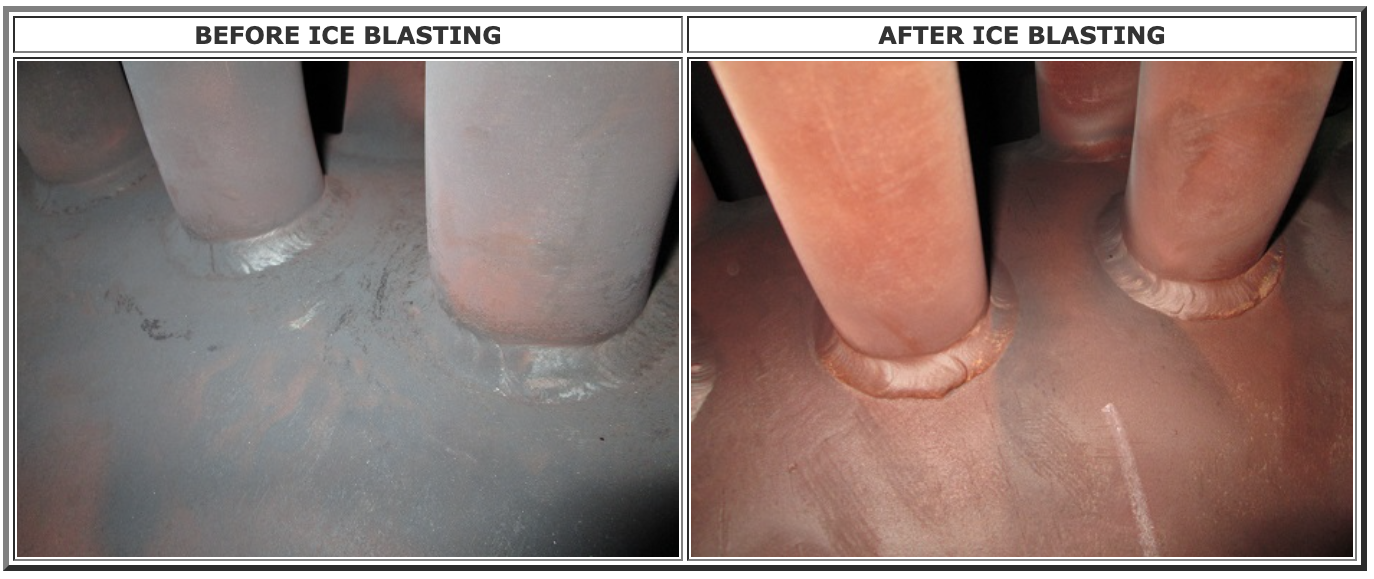

Proper preparation of metal surfaces was critical to success, the maintenance supervisor said. He hired Precision Iceblast Corp for this work because conventional grit blasting might possibly mask surface indications and because use of dry ice eliminated the need for clean-up of debris. PIC’s Keith Boye said a three-man crew with one ice gun cleaned the surfaces required on one HRSG in less than 12 hours (see before and after photos). Spacing was tight, he said, so the smallest technicians on staff were assigned to this job. Also, the physical layout required the use of nozzles designed and fabricated for the application by company personnel.