By Vaughn Watson, Vector Systems Inc

The long-term performance of an SCR system depends on the efficiency of its critical components (Fig 1). While the catalyst often gets all the credit, and all the blame when performance declines, proper maintenance and routine inspection of the ammonia system can alleviate and prevent many factors that contribute to SCR issues in your plant.

It starts with ammonia supply. It is important to work with a reputable and accountable chemical supplier to ensure you are getting the ammonia purity necessary for your system. One way to avoid ammonia contamination is to require dedicated trucks for each haul. Also, requiring certificates and test reports before offload is important for keeping the system free of contaminants like chlorides and calcium, which can damage and plug various ammonia-system components.

Specifying the correct purity grade of ammonia is critical. For aqueous ammonia systems, reagent-grade ammonia (99.95% NH₃ diluted by weight with demineralized water) is the best option. The key differentiation is the purity of the water content of the solution, which if not demineralized could contain soluble minerals that can plug, foul, erode, and damage SCR equipment. Impurities in the reagent solution can lead to vaporizer fouling, ammonia-injection-grid (AIG) plugging, and potential catalyst performance problems. It only takes one bad load of ammonia to experience the headaches associated with ammonia impurity.

For ammonia vaporizers, impurities can plug the spray nozzles or drip rings. They also can cause calcification that hinders vaporization efficiency and can lead to liquid reagent carryover. Channeling and plugging of the vaporizer can lead to NOₓ exceedances and excess ammonia usage.

For electric vaporization systems, inspections of the heater-panel components should be done to ensure all circuits and protective devices are functioning. Inspect the electric heater as well to ensure there is no water intrusion, which can affect heater resistance.

On hot-gas recirculation systems, rotate idle fans weekly, by hand or electrical bump of the motor, thereby ensuring all bearing parts are properly lubricated. Change bearing oil semi-annually using the specified lubricant and check oil levels regularly. Grease bearing seals annually (two or three pumps maximum) using the specified product. Do not use synthetic grease and do not over-grease. Too much grease can leak into the static oil lubricant. Open the coupling cover and regrease the coupling approximately every other month with the product specified.

Inspect the AIG for proper ammonia distribution every outage. Plugging of reagent ports can have a major adverse impact on catalyst performance. If plugging is found, the AIG should be cleaned and its root cause investigated. Note that AIG design can be improved to mitigate plugging and achieve better performance.

For example, specify Type 304 stainless steel for your AIG and eliminate burrs in drilled lances where chips might collect and salt could accumulate.

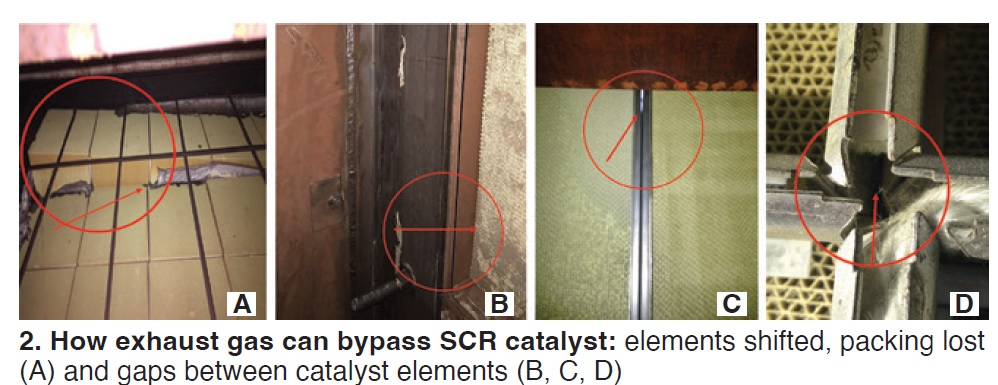

Catalyst should be inspected every outage to ensure its face is not blocked by rust or insulation. This can majorly affect catalyst performance by masking its active pore sites. The catalyst frame also should be inspected for any areas that may allow exhaust gas and ammonia bypass, which can greatly affect NOₓ and ammonia slip (Fig 2).

Ensuring these key maintenance and inspections are done regularly, and addressing problems when they are discovered, are essential to an efficient SCR system. To assist end users, Vector Systems offers comprehensive maintenance checklists for download at no charge for the following equipment: