Tube leaks in heat-recovery steam generators certainly are not rare. CCJ has published many articles on the subject over the years—including one in the first issue (Q4/2003) that touted the benefits of full-penetration welds in HRSG tube panels to improve fatigue life.

That said, why should you read yet another article on tube leaks, these occurring in a couple of high-pressure economizer tubes at the Bouchain combined-cycle plant (sidebar below)? Perhaps because this is the world’s first 9HA-powered combined cycle (COD July 2016), built for flexibility and responsiveness by highly regarded engineers at EDF and GE.

Background

Bouchain, located in northern France, is a 604-MW, natural-gas-fired, single-shaft combined cycle operated by EDF. When commissioned in July 2016 with the first commercial 9HA gas turbine, Bouchain was touted by GE as the world’s most efficient combined cycle, 62.22% according to Guinness World Records. Plus, the gas turbine was claimed capable of reaching full power in less than 30 minutes.

The power train includes a D650 steam turbine, W86 generator, and a horizontal triple-pressure HRSG from CMI. The generating unit reached 45,000 operating hours and 650 factored starts in 4Q/2023. Note that European combined cycles now

are required to operate in a load-following mode and be able to accommodate major load swings.

Understanding why these tubes failed unexpectedly and relatively early in the plant’s life is important for making realistic decisions regarding the design of new units and the operation and maintenance of existing facilities.

Guillaume Grognet, Bouchain’s maintenance mechanical manager, shared his deep knowledge of the plant’s HRSG tube-leak issue—including how the cracked tubes were found, inspected, repaired, results achieved, etc—in a technical paper you can access here. Grognet, an active participant in user discussions worldwide, has made himself available to answer questions from CCJ’s Editorial Advisory Board.

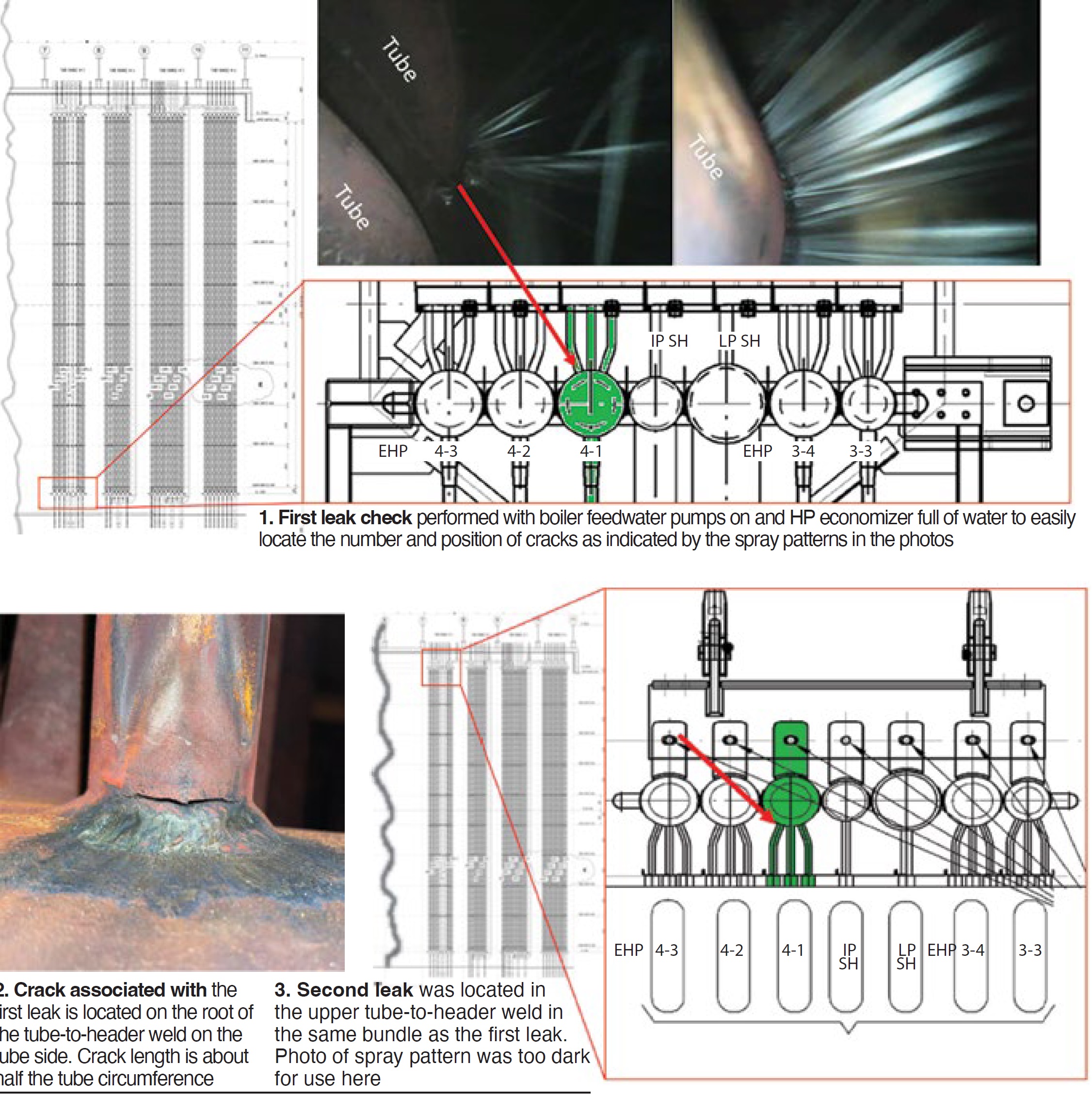

The first leak was identified by water droplets found under an HP evaporator tube bundle during operator rounds in January 2023. Makeup flow increased dramatically over the next month or so to more than 15 gpm. The unit was shut down and a gas-side inspection conducted with feedwater pumps operating and the HP economizer full of water (Fig 1). Access to the crack (Fig 2) in a lower tube-to-header weld, and its repair, were challenging, as Grognet describes in his paper. The unit was restarted without incident.

The second leak was found 3000 factored fired hours later in the same tube bundle, but this time in an upper tube-to-header weld (Fig 3). Access for repair was much more difficult here than in the first case. Typical solutions—(1) cut your way in, make the repair, and weld your way out, or (2) cut an access port in the header, plug the leaking tube, and restore the integrity of the header—were rejected in favor of cutting free EHP 4-3 and 4-2 and lowering those bundles to provide the necessary access. You’ll want to read about how this was done.

A root cause analysis determined thermal fatigue was the primary cause of the failures, as explained in the paper.

Suggestion: As you read through Grognet’s article, jot down your questions. The Bouchain case history is sure to generate discussion at upcoming user group meetings and you’ll want to be prepared to get the information you need. The next conferences of the Australasian Boiler and HRSG Users Group, European HRSG Forum, and the Power Users HRSG Forum are not far off.

Alternatively, you can email your questions to Scott Schwieger (scott@ccj-online.com) and he’ll route them to Grognet or someone on the EAB who can help you.