By Steven C Stultz, Consulting Editor

The seventh annual International Conference on Film Forming Substances (FFS), conducted in Prato, Italy, March 26-28, 2024, was developed and supported by the International Association for the Properties of Water and Steam (IAPWS). The meeting drew 50 participants from 16 countries—including 10 plant owner/operators and representatives from a dozen chemical suppliers.

The event was chaired by Barry Dooley, Structural Integrity (UK), and David Addison, Thermal Chemistry (New Zealand).

Says Dooley, “The major activities at FFS 2024 were multiple presentations and discussion sessions outlining the current status of FFS and their properties in relation to their application as corrosion inhibitors in fossil, industrial, nuclear and other water/steam plants.”

Film-forming substances consist of two main categories of chemicals using the internationally accepted nomenclature: amine-based (FFA, film-forming amine, and FFAP, film-forming amine products), and non-amine-based (FFP, film-forming products) which are proprietary.

Selected conference highlights follow.

Hydrophobicity

Two significant hydrophobicity aspects were stated by Dooley in his conference review:

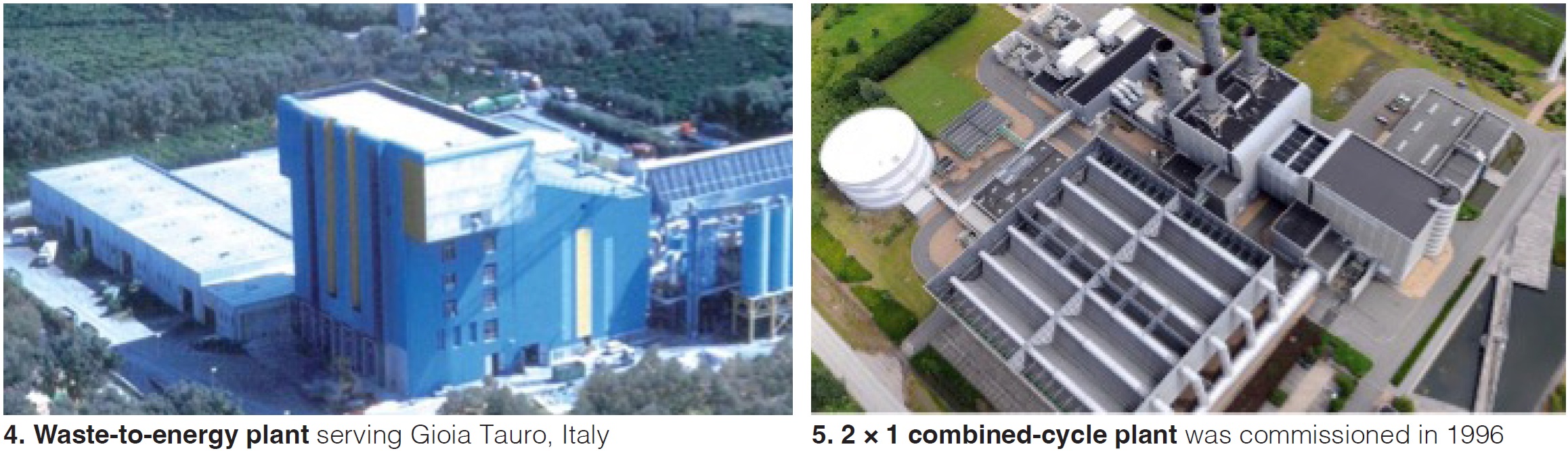

- “As at previous FFS conferences, there were general visual observations of hydrophobic films in the water-touched areas (mainly feedwater and condensate) of plants” (Fig 1).

- More importantly, “A survey of conference participants indicated that the presence of hydrophobic films does not uniquely relate to the reduction of corrosion and the transport of corrosion products but appears to be an artifact of application. Also, surface tension of an FFA (OLDA) is reduced at low levels and related to the contact angle of wettability in this range,” Dooley explains.

And moving beyond the visual, he continues: “A deeper understanding among the attendees was apparent around what are the metrics for success for an FFS program in plants and moving beyond just using the presence of hydrophobicity as a single assessment point.”

Testing methods and analysis were common topic points in many presentations.

Analysis with EIS

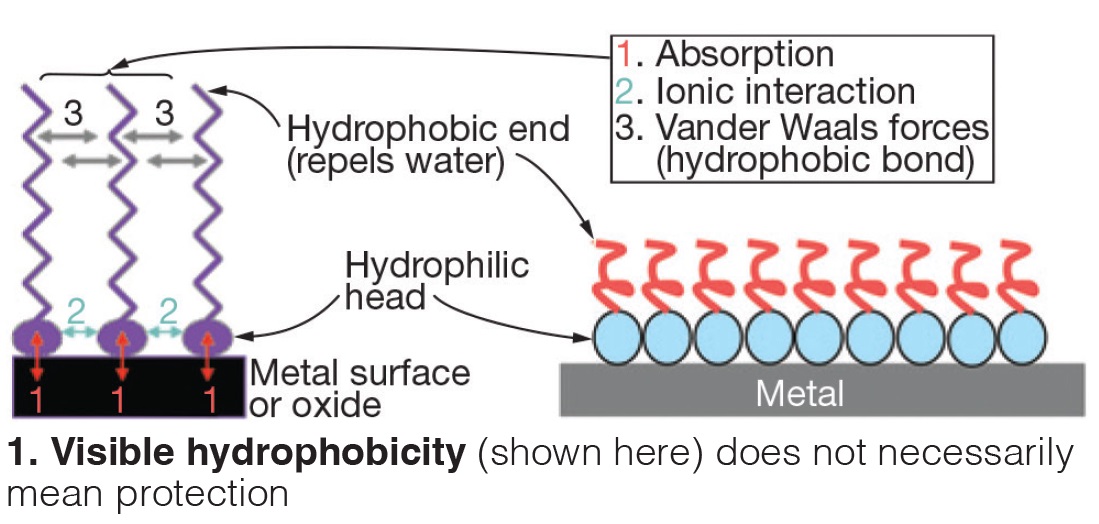

Again, citing Dooley, laboratory experiments discussed at FFS 2024 “provided positive results on monitoring OLDA adsorption onto oxide surfaces, corrosion and corrosion kinetics using EIS (Electrochemical Impedance Spectroscopy). The work on the interaction of the FFA with oxide surfaces rather than metal surfaces was strongly encouraged especially for the other FFS.”

This method was presented on the first day by Deni Jero et al. (Université de Toulouse, France), entitled Electrochemical impedance spectroscopy for continuous in-situ analysis of FFA on carbon-steel surfaces.

Jero looked at water/steam circuits of industrial facilities (carbon steel), localized corrosion, and consequences (materials degradation and damage risk). This led to protection strategies— including the use of film-forming amines.

The challenge, she says, is “continuous in-situ analysis of FFA, of nanometric thicknesses, on rough and corrodible surfaces” for the characterization of thin organic layers.

The proper process must be specified for:

- In-situ (in immersion and continuous).

- Sensitivity to layer thicknesses.

- Working in a surface roughness environment.

- Ability to differentiate between adsorption and corrosion.

- Designed for structural characterization, in this case also using OM-IRRAS (Polarization Modulation Infrared Reflection Absorption Spectroscopy).

The analysis technique discussed: Electrochemical Impedance Spectroscopy (EIS).

The study focused on the following:

- OLDA (Oleyl Propylenediamine) adsorption kinetics and structural properties.

- Influence of temperature variation on the OLDA layer.

General conclusions showed the mixed layers of OLDA and corrosion products, simplified in Fig 2.

The conclusion of this study: For optimization of FFA quantity and injection frequency, EIS is a useful tool to monitor FFA on carbon-steel surfaces.

Other applications in water/steam cycles

Successful applications of FFS for industrial-boiler pre-service cleaning and preparation, and for waste incineration boilers, were discussed for the first time at an FFS conference.

Industrial pre-commissioning cleaning

Dylan Harrison, Visentia Ltd, New Zealand, discussed Pre-commissioning cleaning of new industrial boilers with the use of ODA (Octadecylamine).

His case study was a 30-MW biomass boiler (Fig 3).

Traditional pre-commissioning boilouts (various chemistries) are intended to remove mill scale, iron oxides, slag, abrasing dusts, greases and oils, and manufacturing debris—such as nuts/bolts/washers/tools. This also helps minimize corrosion during refractory drying.

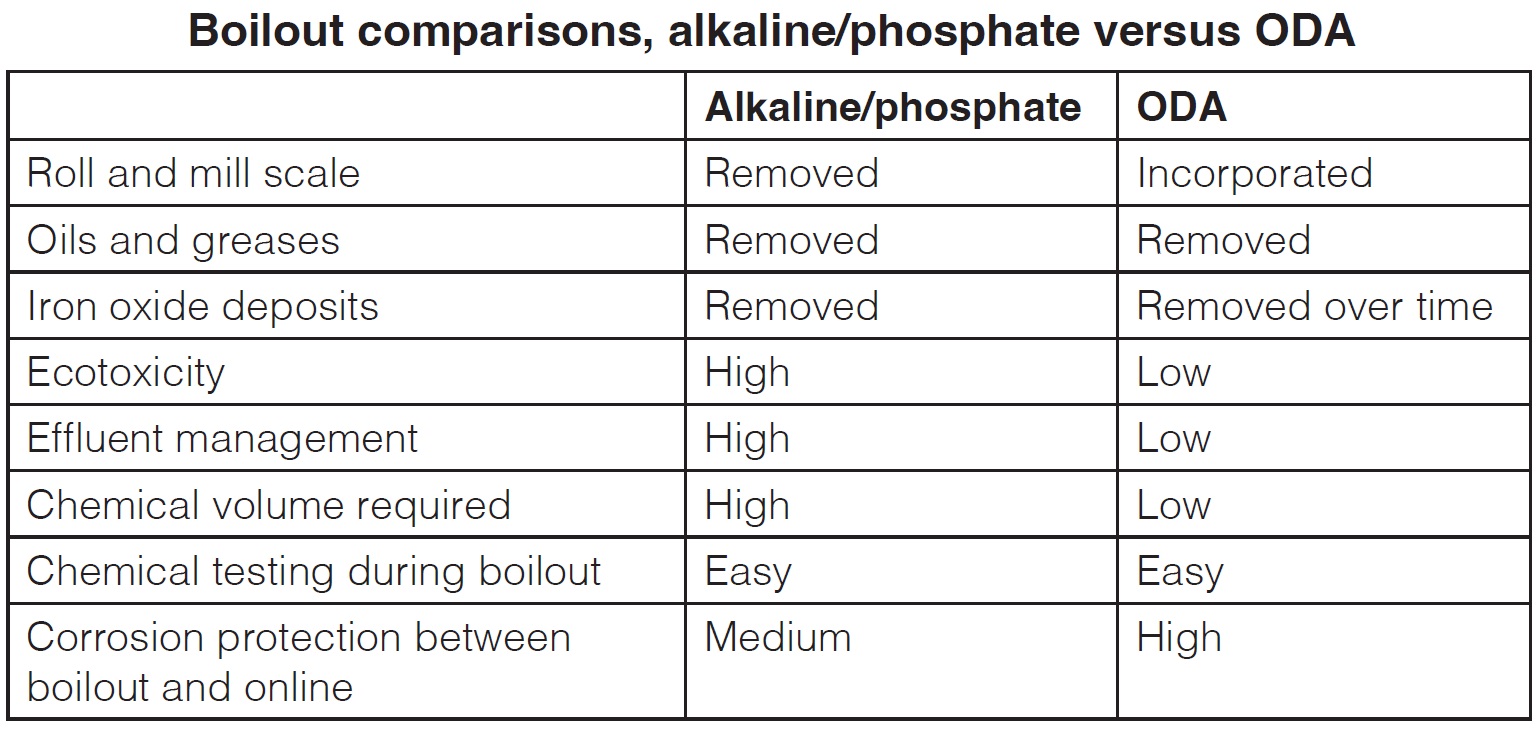

Harrison offered a comparison of results, alkaline/phosphate versus ODA treatment boilout, shown in the table. His discussion included lessons learned, along with cautions and solutions.

Waste-to-energy

F Carruba, Kurita Europe (Italy) and V Di Massa, Ecologia Oggi (Italy) presented Transition of two waste-incineration boilers in Italy from traditional treatment to Cetamine®. The 16-MW municipal solid waste plant (Fig 4) was commissioned in 2005, with two boiler systems.

Boilout is intended to remove macroscopic residues from the system (deaerator, drums). Overall, changing the procedure with Cetamine reduced chemical consumption by 97%, water consumption by 55%, and boilout time by 54%.

Presenters explained that in September 2022, the plant switched from standard boilout procedure to boiling out with Cetamine. At the end of 2022 the plant switched to Cetamine for both passivation and continuous treatment and “total iron levels in the system were significantly reduced.”

Cetamine was shown as suitable technology during the process of alkaline boilout, passivation, and continuous treatment. All steps can be covered with one product, and the change allowed significant reductions in chemicals, water, and time.

Selected plant updates

Anthony Senecat, Engie Laborelec, began the FFS 2024 sessions with Two cases of FFA use in Engie powerplants: a 2 × 1 combined cycle commissioned in 1998, now in flexible operation (daily start and stop), and a nearly-retired coal-fired station commissioned in 1979.

In the first (Fig 5), iron values were compared from 2008 to 2018, before and after FFA dosing. A consistent evaluation between feedwater and condensate showed a positive impact of FFA on iron transport.

The second plant (Fig 6), originally baseload, is now limited to support for a neighboring blast-furnace-gas boiler. Dosing is used to minimize preservation costs for the water/steam cycle when off line.

In this case, dosing implementation has been difficult with large deviations in CACE (conductivity after cation exchange) readings. In summary, “FFA implementation is not a straightforward process.” There is to date no explanation of the high degassed CACE values. However, dosing FFA prior to the end of continuous operation appears beneficial to the water/steam cycle.

Berkeley Booth, Veolia (US), presented Polyamine Plus controls corrosion in large utility boiler. Subject plant: The four-unit 2400-MW coal-fired Jim Bridger Plant of Rocky Mountain Power, a subsidiary of PacifiCorp. The plant operates in flexible mode with the 600-MW boilers operating as low as 80 MW on any given day.

Polyamine Plus is a unique blend of FFA and non-amine filming product. Discussed was Steamate PAP7010. Says Booth, “After eight months of feeding PAP7010, the condenser hotwell, feedwater, boiler, and steam turbine were inspected for evidence of product coverage.”

The feedwater heater and other locations, including stream turbine and condenser, had visual presence of hydrophobicity.

This implied “protection over the entire steam system” with cost savings. Following the first unit test, all boilers were switched over to PAP7010. Dosage was optimized to 0.5 ppm.

Other updates on recent FFS experience included applications for supercritical units, “raising questions on additions of FFP when using oxygenated treatment.”

For example, Nalco’s David Little discussed Non-amine filming for supercritical power plants featuring a 950-MW unit with varying load in Pennsylvania and another coal plant in the Midwest operating between 400 and 800 MW. He offered “A tale of two stations” and use of Powerfilm 10000, both meeting trial objectives with positive results.

Both trial units suggest that supercritical applications should be limited to non-amine FFPs. Trials are ongoing.

David Addison, Thermal Chemistry, presented Application of ODA in an 8-MW electrode boiler in Queenstown, New Zealand. This trial is ongoing.

One conclusion: “Successful initial application of ODA to resolve commissioning chemistry issues” showed a “sudden and effective reduction in corrosion rates (total iron levels) when applied.”

Rounding out the sessions

Fulfilling the comprehensive 2024 agenda were the following:

- Environmental and ecotoxicity wastewater considerations (Thermal Chemistry, New Zealand).

- ODA in secondary circuit: Efficiency against corrosion in layup (EDF Research, France).

- FFA behavior in water/steam cycle using a recirculating loop (Canadian Nuclear Laboratories, Canada).

- Available FFA analytical methods (Reicon, Germany).

- Application of FFP/amine in two cooling systems (Evides Industriewater, The Netherlands).

- Filming product application in PWRs/PHWRs (IPRI, US).

- Impact of FFA on (nuclear) steam-generator sludge properties (EDF, France).

- Flow-accelerated corrosion in aqua ammonia systems (Yara, The Netherlands).

- FFS: Needed research and improved operation (Dooley and Addison)

- Dosing, monitoring, and control—a practical approach (Wolfgang Hater, Germany).

- Acting for an ethical water performance (Odyssee Environmental, France).

- FFS as an efficient heat-transfer enhancer (Kurita, Japan).

- Photometric methods for detecting FFAs in water (University of Belgrade, Serbia).

- The effect of adsorbed OLDA on contact angle (MHI Group, Japan).

- Impact of various FFS on condensation (Nalco Water, Australia).

Ongoing work and IAPWS

One of the leading questions among users worldwide remains whether FFS application can be changed from an FFP to an FFA, or vice versa, for economic reasons.

A panel discussion held on the final day of FFS 2024 covered the following, itemized by Dooley: The seven-year suite of FFS international conferences has been a key part in the development of the IAPWS Technical Guidance Documents (www.iapws.org) and has helped to advance proper use of FFS as part of the aims of the IAPWS Certified Research Need (ICRN), which was scheduled for completion and approval at the IAPWS 2024 meeting, June 23-28, in Boulder, Colo.

This ICRN is intended to help drive additional research into the critical, currently unknown fundamentals of FFS which will help to lower the application risks in plants, reduce failures, improve the performance of applications and eventually allow FFS to be changed at plant sites.

An outline of the research requirements, provided by Dooley, follows:

- Effect of FFS on growth mechanisms of Fe, Cu, and Cr oxides in water and steam. Better understanding will help to explain the effects of surface roughness and overdosing of FFS. This is recognized as the current major deficiency in understanding how FFS work in providing protection. Future work is needed on the interaction of FFS films with existing oxide/deposit surfaces of Fe3O4, Fe2O3, FeOOH, CuO and CuO2 in condensate/feedwater and boiler/evaporator water environments.

- Relation between surface coverage and degree of corrosion protection.

- Effect of FFS on boiler and HRSG tube failures (under-deposit corrosion and corrosion fatigue) and stress-corrosion cracking.

- Film formation, kinetics, structure, equilibrium and stability (film thickness and porosity on water- and steam-touched oxide surfaces) for all FFS, especially FFP.

- Thermal hydrolysis and decomposition products for FFA, and especially FFP under oxidizing and reducing potential conditions.

- Uncertainty of adsorption onto oxide surfaces for all amine and non-amine FFS and how films are affected by other additions to the FFS.

- Characteristics of film layers and correlation with surface protection.

- Whether protection of superheated steam surfaces can be achieved for amine and non-amine FFS.

- Increased steam-turbine performance for amine-based FFS (ODA) has been illustrated but research is needed to determine if other FFS reduce the surface tension.

- Impact on membranes (EDI and RO).

- Impact on ion-exchange resins.

- Compatibility of FFS with other chemical additives (for example, chemical cleaning agents and dispersants).

Wrap-up

The FFS conferences are developed and supported by the International Association for the Properties of Water and Steam (IAPWS). FFS 2024 was arranged in Prato, Italy, by Mecca Concepts, Australia, and Combined Cycle Journal, US. Sponsors of FFS 2024 were Swan Analytical Instruments, ECOLAB, Kurita, and Anodamine.

Conference information is available at https://filmformingsubstances.com.

Contact Barry Dooley (bdooley@IAPWS.org or bdooley@structint.com) for further information on FFS and the IAPWS FFS conferences.