2024 501F BEST PRACTICES AWARDS

Red Oak Power

Owned by TigerGenCo

Operated by NAES Corp776 MW, gas-fired 3 × 1 combined cycle equipped with Siemens 501FD engines, Foster Wheeler HRSGs, and a Toshiba triple-pressure reheat steam turbine

Plant manager: Dave Carroll

Editor’s note: Before reading this Best Practice, consider perusing CCJ’s backgrounder on Arnold Group’s steam-turbine warming and advanced insulation system.

Challenge. Steam-turbine cold-metal temperatures after lengthy shutdowns required between six and 10 hours of startup time to comply with STG warming curves. During the startup period, gas-turbine loads were restricted to prevent rotor-long conditions in the steamer. This increased the consumption of natural gas and consumables and produced higher emissions.

Solution. Red Oak personnel worked closely with Arnold Group, a subcontractor to Toshiba America Energy Systems Corp, to install Arnold’s single-layer steam-turbine shell warming system during an HP/IP turbine major outage. Site I&E technicians worked with Arnold and Toshiba to integrate new startup curves and logic in the STG control system.

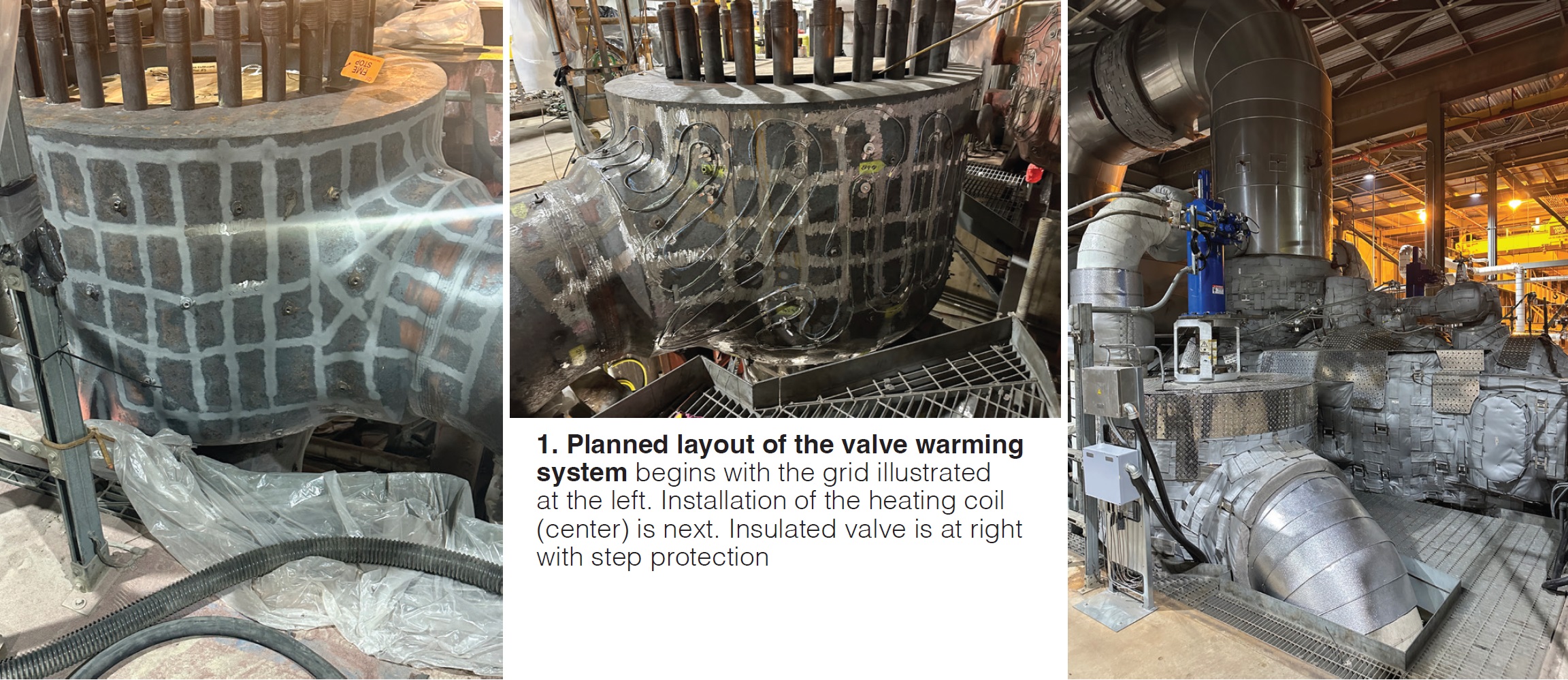

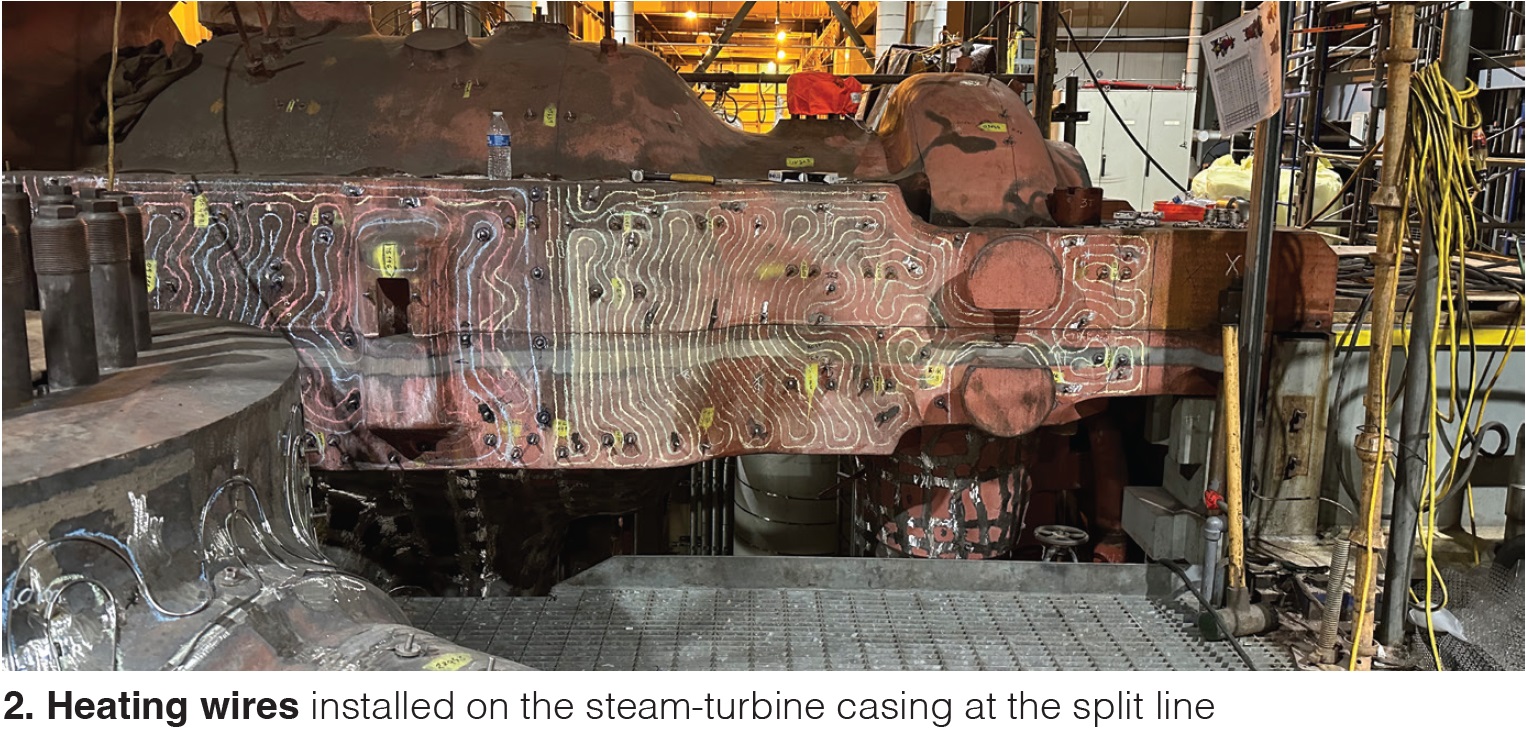

Red Oak was responsible for removing old insulation and pins before the casing was ice-blasted clean. Next, Arnold technicians installed the high-tech warming/insulation system on the main steam valve (Fig 1) and turbine (Fig 2). After post-outage testing of the STG, Red Oak and Arnold personnel commissioned the warming system, which maintained turbine metal temperatures at the optimal level for startup.

Results. First start after the extended shutdown was defined by a greatly reduced startup time compared to what had been customary after a shutdown of similar timeframe. The reduction in start time was 68.3%. The reduction in fuel consumption and in CO2 emissions over that period was 63%. Staff estimated that the savings in cooling-tower makeup and ammonia consumption at 68% and 81%, respectively.

There were more benefits attributed to the warming/insulation system but most difficult to quantify—including the following:

- Less wear and tear on startup bypass steam valves and attemperators.

- A uniform startup period allowing those bidding the plant into the energy market greater flexibility because they did not have to consult a chart to determine the startup time.

- Less gas consumption makes the plant more competitive when bidding to start on marginal days.

- Reduced stresses on the asset contribute to a longer productive lifetime, as evidenced by forecasts of unit operation out two decades or more.

Project participants:

Marc Hain, maintenance manager

Mike Brady, planner

Mike Malizia, I&E technician

Jason Pyzik, I&E technician

How to develop a successful warming project

Arnold Group installed its first single-layer steam-turbine shell warming system on a GE D11 machine in 2017. Today there are two-dozen such systems in service worldwide—most in the US. Arnold’s Norm Gagnon says early interest in this system was driven by regulatory and market requirements demanded of US power producers. But with many US rules and practices adopted by other countries, interest today is worldwide.

Many improvements in the original system, often focusing on software, were made during the technology’s formative years to extend its capabilities—such as greater operational flexibility to profit from ancillary services and better control of upper/lower casing differential temperature and cooldown to shorten outages. Improvements are on-going with lessons learned factored into future projects.

Concerning heating-system capability, Gagnon says a rule of thumb is that for single-casing units, the turbine first stage typically is held at 750F, but a higher temperature often is possible. For double-casing units, the limit is about 450F.

Arnold credits its highly integrated relationships with turbine OEMs and plant owner/operators as critical to project success. The need for excellence in communications among the parties is at the top of Gagnon’s list. Extensive pre-outage coordination and planning—including well-defined scopes of work and responsibilities—are required to assure activities don’t creep outside the critical path. He cited coordination of laydown space in clearly labeled areas governed by a phased layout plan as very important.

Regarding schedule, Gagnon says turnarounds from purchase order to startup may be as short as six months—depending on shop availability and other project-specific conditions, equipment availability, etc. But 12 months is typical. With impeccable coordination and cooperation, warming systems can be installed in about 30 days, in lock-step with a major inspection. This given Arnold’s extensive experience in the hand-crafting of heating coils, controls integration, and system commissioning.

Gagnon closed out the phone interview with CCJ editors while in China completing a successful installation, noting that the payback on a “shining-star” project achieved a payback of one year.