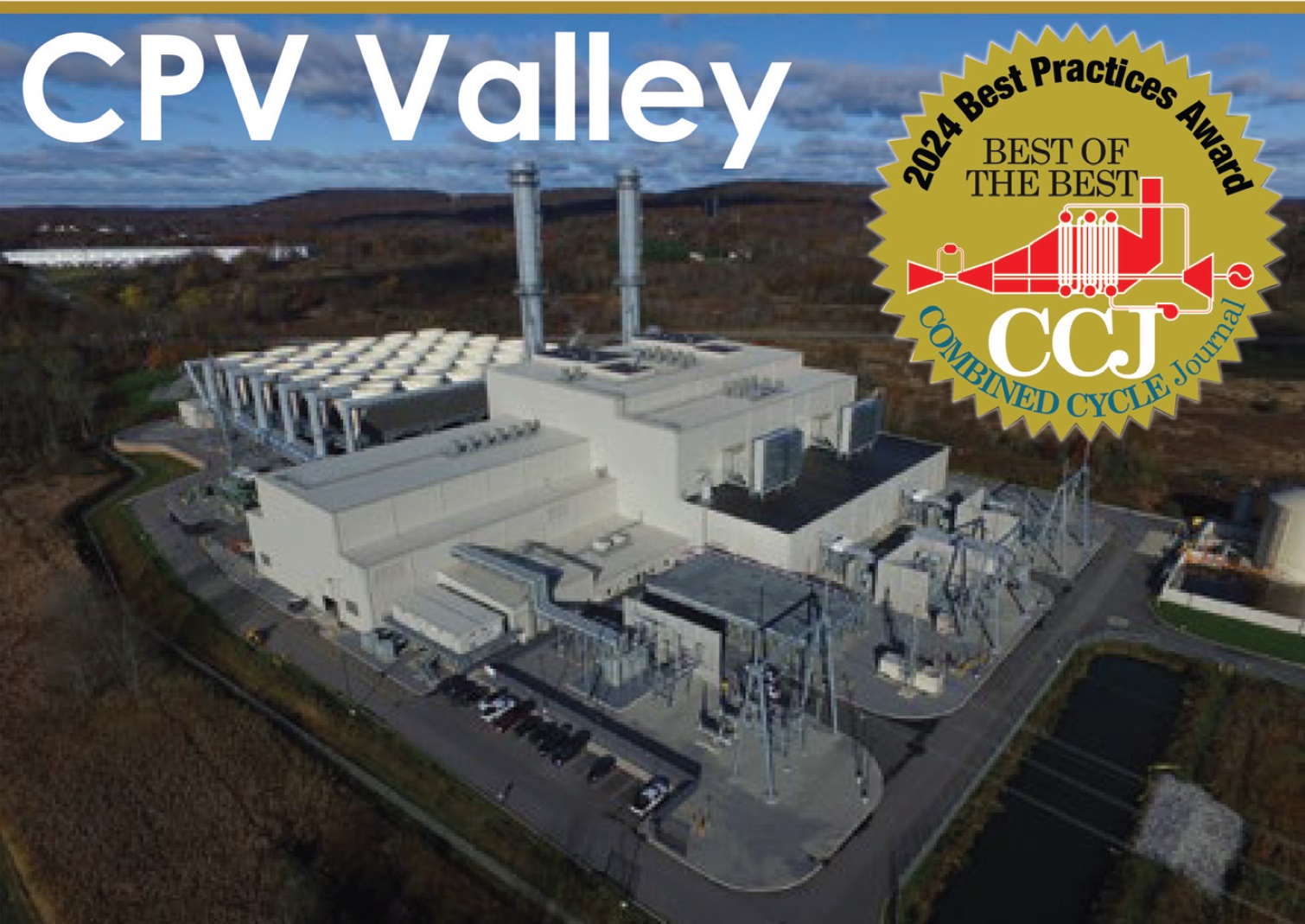

2024 501F BEST PRACTICES AWARDS: BEST OF THE BEST

- Anti-icing system prevents snow-related derates, outages

- The road to reliable ultrafiltration

- Experience upgrading Siemens’ T3000 V9.2

CPV Valley Energy Center

Owned by CPV/Diamond Generating Corp

Managed by Competitive Power Ventures

Operated by DGC Operations LLC

680 MW, gas-fired 2 × 1 SGT6-5000-powered combined cycle, located in Middletown, NY

Plant manager: Michael Baier

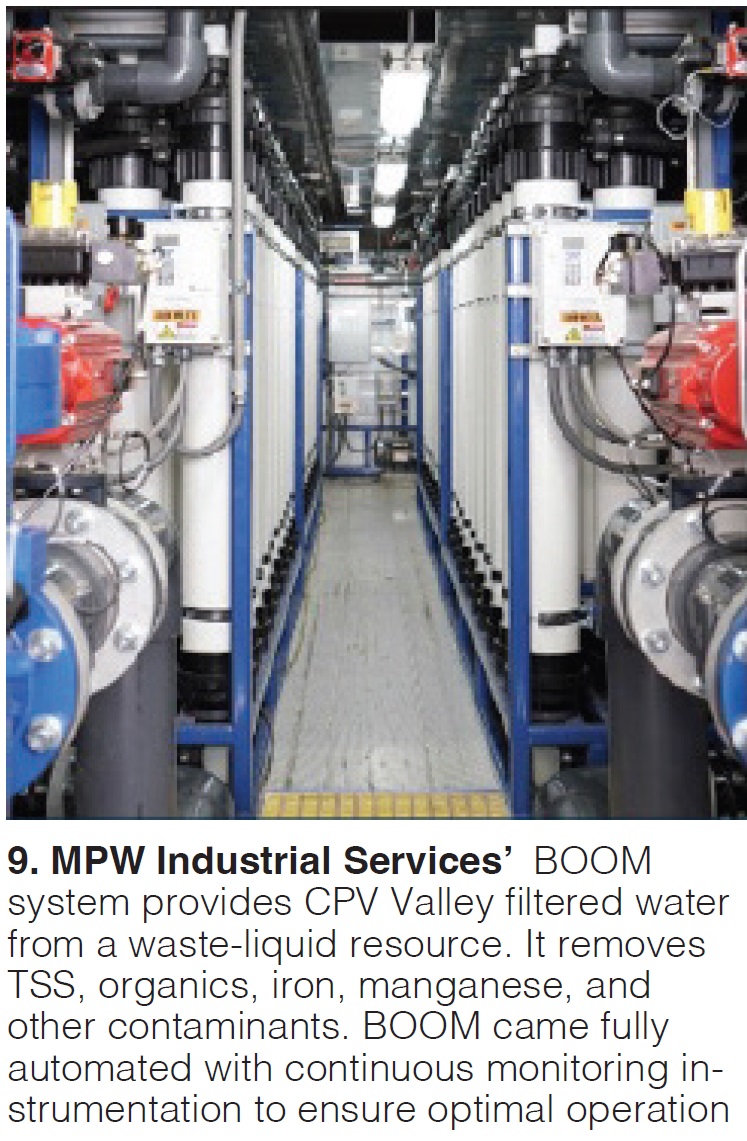

Challenge. An ultrafiltration (UF) system was installed during construction of CPV Valley’s water treatment plant. However, it could not manage the purity of the city-supplied waste effluent, failing continually. MPW Industrial Services was asked to provide a UF trailer—a/k/a/ BOOM—to help supply plant-quality water during plant commissioning. It performed without issue.

Solution. MPW designed a 40-ft “container” for installation inside the water-treatment building to replace the existing in-house UF system. The container features two UF trains, each consisting of 30 modules, which treat the local POTW (Publicly-owned Treatment Works) water supplied to the plant. This system produces up to 300 gpm of filtered water. The processed water then is piped to CPV Valley Energy Center’s in-house reverse-osmosis system.

Finding the appropriate water-filtration solution is often a challenging task for plants in the power, pulp and paper, and fossil-fuel industries. Faced with high upfront capital costs and the lack of support staff to maintain a comprehensive filtration system, industrial companies can lack solutions to fit their specific needs. MPW Industrial Services provided CPV Valley a fully managed system that delivered a dependable clean water supply to the plant. It is referred to internally as the BOOM (Build, Own, Operate, Maintain) water system.

MPW built the system at its fabrication facility in Ohio. Equipment was installed in DOT enclosures for weatherproofing. MPW personnel installed all interconnecting pipe, power, and site-controls onsite.

After installation was complete, MPW evaluated the system’s operation. During the startup phase, it verified that effluent quality and quantity specifications were met. BOOM system PLC controls were integrated with the existing water-treatment-plant PLC logic that controls the POTW raw-water pumps supplying water to the plant. The BOOM system calls for a raw-water pump to start when the service-water tank level drops below a specified level (Fig 9).

Results. Currently, the system is running in normal operation. MPW assigned a field service technician (FST) to perform site visits for up to eight hours per week, to review the operator’s log, adjust chemical dosages as required, and make any other mechanical adjustments when necessary—plus perform preventive maintenance. Additionally, FST provides remote monitoring services via TeamViewer as needed to maintain the system.

The primary FST assigned to the site was made available for 24/7 additional emergency support while candidate FSTs were trained to provide services to the site for backup. Additionally, MPW provided staff training on the proper emergency operation of the system.

Remote monitoring has become one of the most important innovations over the past decade. It has decreased the need for onsite support staff, leading to improved plant safety, and contributing to reduced downtime, which usually promotes higher efficiency.

Pump motors in the BOOM system are automatically controlled by an electrically efficient variable-frequency drive. By using VFD controls, plant operators can manipulate the pump and impeller speed at a varied rate, allowing the motor output to match the system requirement for improved pump performance. This technology, as well as all the other technology used in the BOOM process, is compatible with a variety of other mobile industrial water systems, simplifying integration.

Project participants:

Dave Engelman, operations manager

Tommy Viertel, lead mechanical technician

Josh Zimmer, plant engineer