Edgewood Energy LLC

Owned by J-Power USA Development Co

Operated by NAES Corp

88 MW, gas-fired 2 × 0 LM6000-powered peaking plant, located in Brentwood, NY

Plant manager: Kenneth Ford

Background. Edgewood’s gas-compressor (GC) skid is comprised of three screw-type compressors served by a common system for removing lube oil entrained in the natural gas at the skid discharge by way of coalescing scrubbers.

Challenge. During a routine startup, a mist was noticed emanating from the relief-valve discharge piping of one compressor. The mist was quickly determined to be compressor lube oil and the GC skid was shut down by manual E-stop.

Staff investigated the event and concluded that one relief valve had lifted prematurely, causing a spill of approximately 50 gallons of lube oil spread over a large area within the facility. The site’s spill vendor was mobilized and the affected area cleaned up—including the removal of several drums of blue stone from the site. Personnel sent the affected relief valve offsite for a standard overhaul and testing.

A post-incident review found that the GC skid controls did not receive any alarms, nor any indication, that the relief valve had lifted. Manual intervention was required to stop the incident and prevent additional release.

Had this occurred in the evening, the likelihood of the spill going unnoticed would have been extremely high, with the anticipated spill volume being far greater than for this incident. Personnel focused on how to control such an event in the future, where a potential spill would be detected early enough to initiate an automatic shutdown of the skid.

Solution. Management evaluated several options to prevent a recurrence of the event—including acoustic monitoring of downstream relief-valve piping to detect flow, and physical monitoring of relief-valve position. Wired and wireless installation was considered for both options.

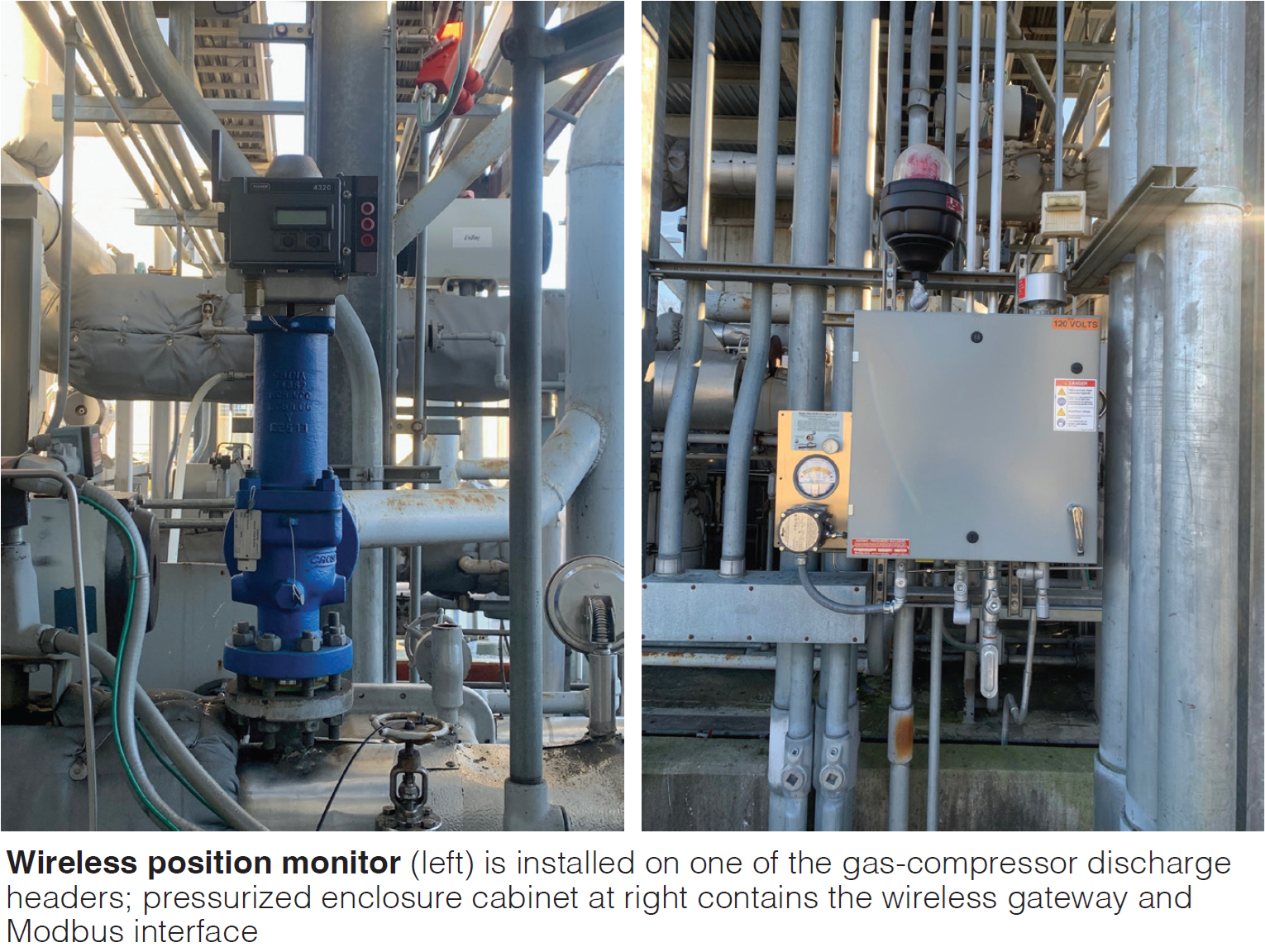

Following research that included consultation with potential vendors and other powerplant managers, Edgewood management decided the most suitable option was to install wireless monitors on each of the valves to detect when any one moved from its closed-seat position. Minor modification of the relief valves was required to allow installation of position-detection hardware.

The monitoring devices were installed and connected through a wireless gateway to the GC-skid control system. Finally, system logic was modified to automatically shut down the skid should any of the valve monitoring devices detect a valve not in the closed position. Additional alarms and shutdowns were created to support the effort.

Results. Since system installation and commissioning, no relief valve has lifted unexpectedly. Annual checks of system functionality are conducted to help ensure the system will continue to function as desired.

Project participants:

Michael Citarelli

Anthony Angieri

Ed Lozada