The HRSG Forum, led by Co-chairs Bob Anderson of Competitive Power Resources and Barry Dooley of Structural Integrity Associates, continued its tradition of offering excellent user-driven content in its recent virtual meetings. The HRSG Forum in-person meeting, in collaboration with Power Users for the first time, is scheduled for Atlanta the week of June 12. Details coming soon.

Steve Bates and Steve Harvey shared the details of a catastrophic incident at the 2 × 1 501G-powered Wise County (Tex) Power Plant in which natural gas accumulated in the condenser during an extended outage and exploded when a welder attempted to repair an external pipe. In the opinion of the editors this presentation could be one of the most valuable safety briefs you’ll receive if you have a combined-cycle plant with a fuel gas heater (FGH). An abridged account follows.

As a result of a failure of a main lead in the steam turbine/generator, the facility was in a steam-turbine outage in January 2022 during which the Wise County GTs remained “available” to the grid (with fuel at pressure up to the FGH stop valves). With the plant experiencing numerous issues with the FGH (for example, leaking gas isolation valves) and its leak detection system (prone to false alarms), and other factors, natural gas found its way to the condenser through the IP water-side supply line (the source of heat for the FGH).

The plant was down for 10 days, but with cold weather in the forecast, the gas turbines were started to build up pressure to about 50 psig in the HRSG to prevent freezing. The steam pressure in the HRSG provided the motive force to move the gas that had been accumulating in the IP drum to flow down the steam piping to the condenser.

When a welder arrived to repair a 1-in. pipe connection on the outside of the condenser, the arc ignited the gas and the subsequent explosion blew out six rupture discs on top of the unit, caused bolting threads on the LP steam-turbine cover to fail, and damaged internal structural supports. Rupture-disc parts were found all over the plant site. The explosion was heard and felt throughout the plant.

Mercifully, no one was injured (not even the welder), no condenser tube leaks resulted, and the LP section of the turbine suffered no internal damage.

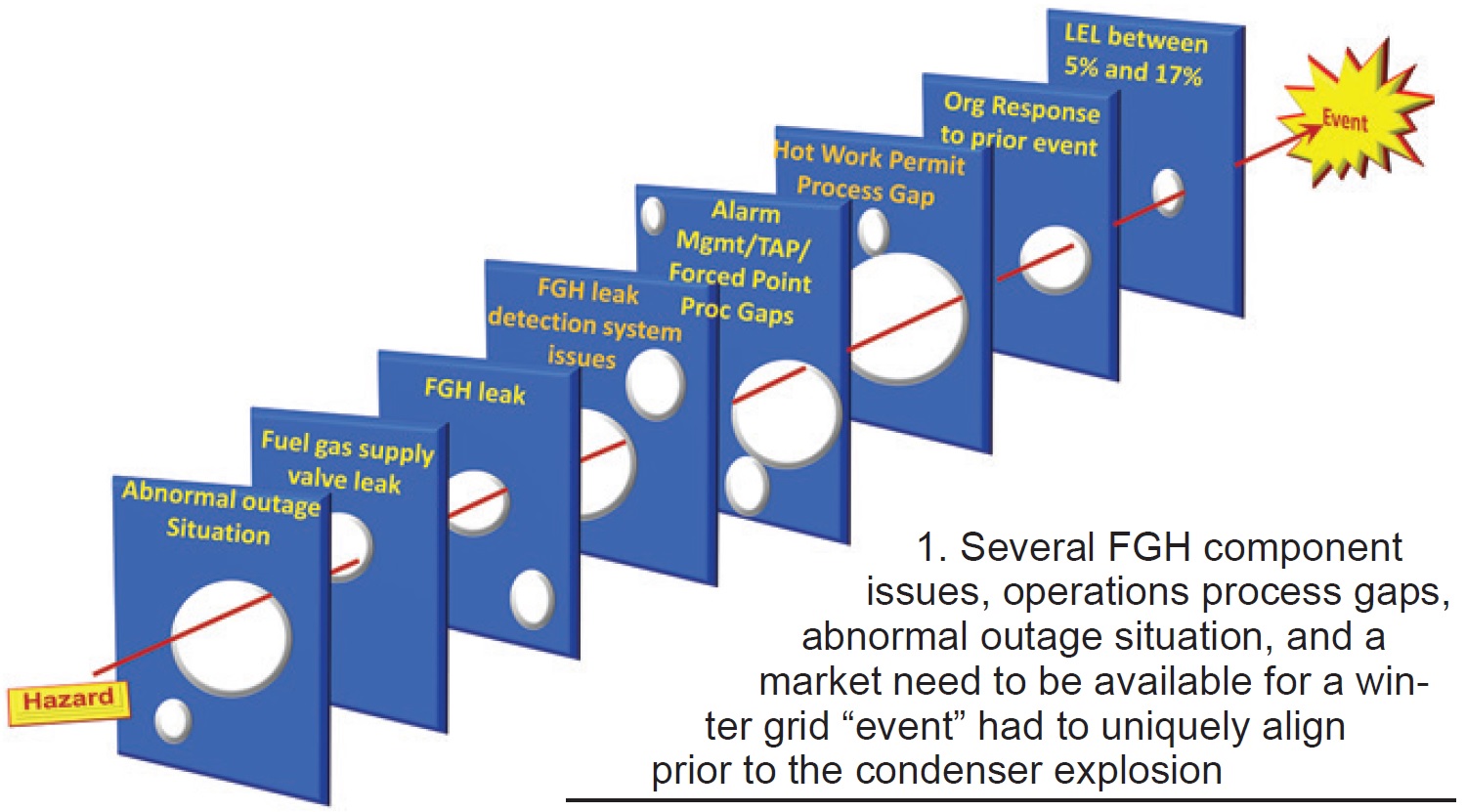

Bates covered the events (Fig 1) at the plant which had to uniquely align for this incident to even be possible, as well as his company’s fleet-wide assessment and recommendations to avoid a similar incident elsewhere, including the following:

- Eddy current test FGH tube bundles and perform leaking testing at least every six years.

- Utilize more robust inserts when plugging tubes.

- Ease plant staff access to vent valving and instrumentation.

- Establish fleet standard critical preventive maintenance guidelines for FGH systems.

- Perform comprehensive FGH system design review.

- Install permanent redundant methane detectors on air ejectors with feedback to control system.

This presentation is not available online. Those interested in learning more should contact Bates directly.

Upcoming HRSG Events

|

|

|