The nine Best Practices summarized here conclude CCJ ONsite’s coverage of more than 60 entries in CCJ’s awards program that were recognized by the judges in 2018 for their value to owner/operators of plants powered by gas turbines. Judging of the 2019 entries begins in March.

Starting-motor trolley rail increases outage efficiency, safety

Florida’s Mulberry Cogeneration, owned by Northern Star Generation Services and operated by CAMS, operates daily on a contractual peaking basis and provides service during peak daytime hours for the seven-month summer period, and during the morning and evening peaks for the five-month winter schedule. This equates to nearly 500 starts annually.

The demanding operational profile requires absolute dependability of the starting motor, located in the auxiliary compartment. Staff, led by Plant Manager Allen Czerkiewicz, found that having a spare motor and rotating it out every year for maintenance ensured high reliability. However, that was not an easy task. Access to the starting motor was blocked on one side, and limited on the other side, by the water-injection skid. Top access was prevented by inlet air ductwork.

To swap-out the motor, the auxiliary compartment roof had to be unbolted in two sections, lifted, and walked back. After fire detection and other conduit were removed, the side walls of the compartment were unbolted, and a crane lifted them out of the way.

The motor then was lifted by chain hoist and rolled out of the compartment on the installed trolley beam, which was mounted to the underside of the inlet-house frame. When outside the compartment, the motor was lowered to the ground and a crane moved it to an awaiting truck. The entire evolution took four to six people an entire day.

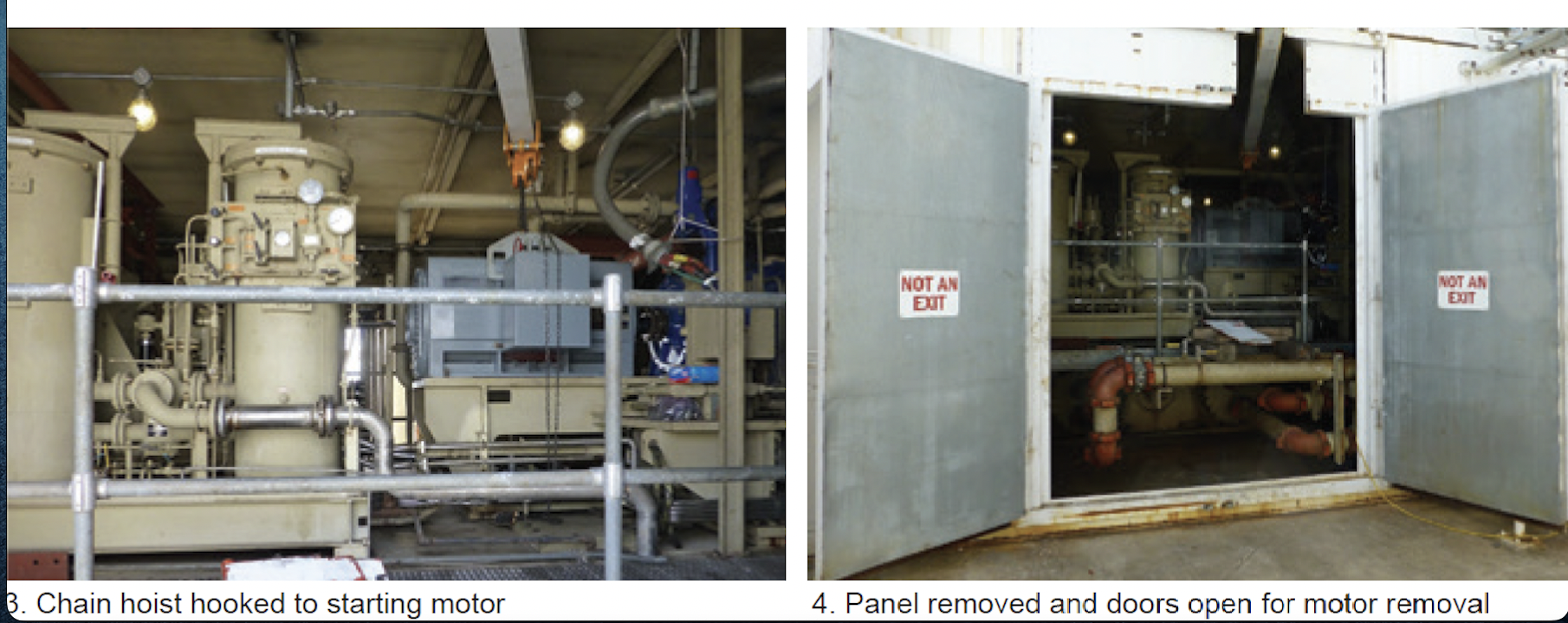

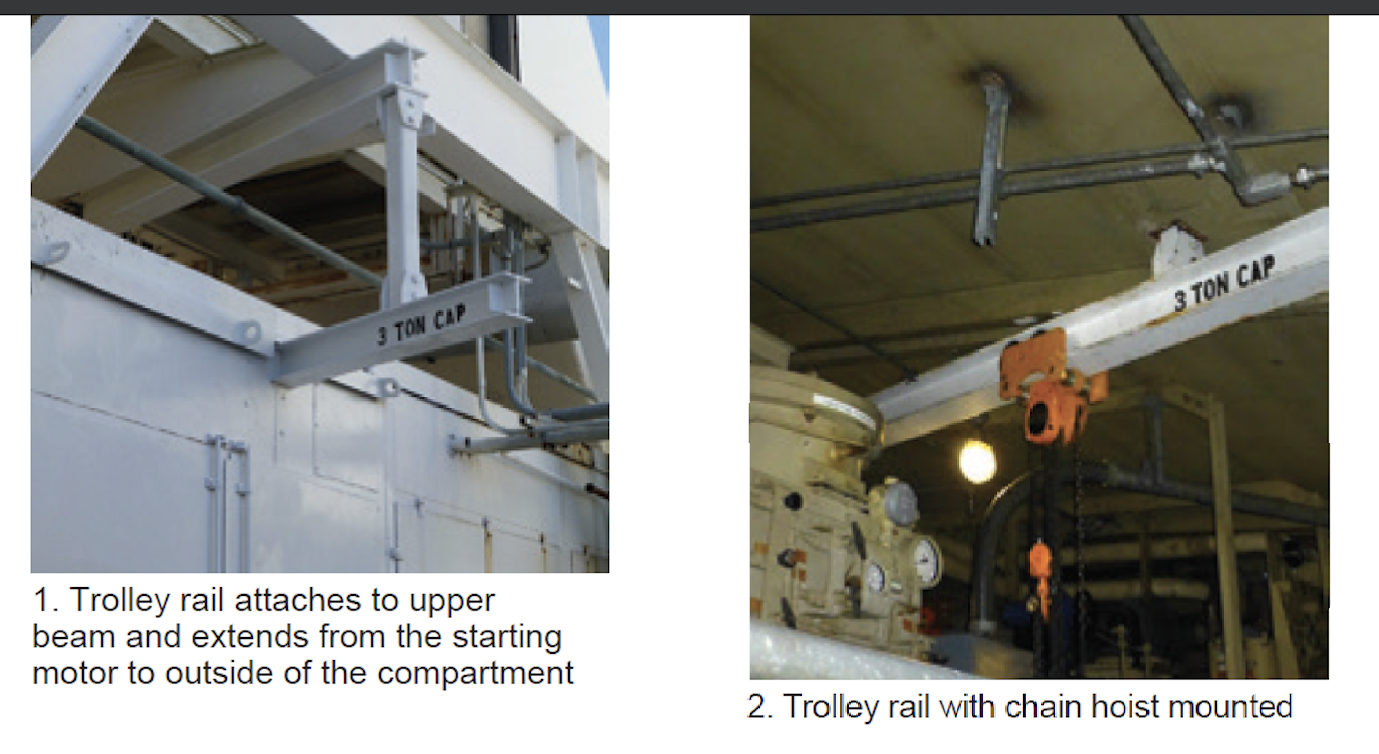

Team Mulberry looked at several possible solutions to make this job faster and safer, settling on the installation of a lower trolley rail that attaches to the existing trolley rail (Fig 1). The new rail extends down into the auxiliary compartment (Fig 2) and follows the existing beam out through the side of the compartment. The roof penetrations are sealed to retain CO2 fire system integrity.

The new configuration allows the motor to be lifted (Fig 3) without removing the roof, the side walls, or the conduit. Then it is rolled outside the compartment and lowered to the concrete pad. A forklift moves the motor to the warehouse. Only a small sealing panel must be unbolted to open the side wall doors for easy access (Fig 4).

First use of the modified system was as easy as had been foreseen and resulted in a huge man-hour saving. Plus, a safety improvement, by eliminating the need to handle large roof and wall sections by crane. The removal process for the motor now takes two men only two hours, saving cost and freeing-up plant personnel for other outage tasks.

Step challenge generates health, occupational benefits

Many people think of health only in terms of illness, but it actually is a positive concept that covers your physical, mental, and social well-being. Physical activity improves every aspect of your health: Adults typically start to see tangible health benefits if they engage in at least 150 minutes of moderate physical activity weekly—such as a brisk 30-min walk five days a week.

Such a fitness program helps reduce the risk of a heart attack, make it easier to manage your weight, lower your cholesterol and blood pressure, reduce your risk of Type 2 diabetes, and speed your recovery from injuries and illnesses. Further, it generally increases your energy, elevates your mood, and improves your sleep.

One of the initiatives in Ferndale Generating Station’s 2017 Safety Improvement Plan was a wellness program that included a plant-wide step challenge. To foster a positive attitude toward it, participation in the program was encouraged on a strictly voluntary basis.

Employee teams were created with a view to ensuring competitive equality. Personnel were categorized into four disciplines—administrative/management, control room operator, plant operator, and maintenance—then randomly selected to create four teams with one person from each discipline.

Each participant was provided with a Fitbit activity tracker to log the number of steps performed on a daily basis. All were encouraged to “friend” each other on the Fitbit app. The overall goal was to encourage more activity both at work and at home.

As part of the challenge, a recognition plan was established. Participants’ steps were tallied weekly and posted. At the end of each quarter, members of the team who recorded the most average steps received gift cards and recognition during the monthly safety meeting.

To ensure continued participation of those who were not leading the group on step counts, weekly challenges, pitched to different levels of difficulty, were established: flights of stairs, difficult-to-achieve step goals, and even bracketed step challenges to keep people engaged. Raffle tickets also were issued to participants based on personal challenge results, which made them eligible to win one of five prizes at an annual celebration.

The entire staff accepted the challenge, which helped create camaraderie as well as a spirit of friendly competition. All participants finished with positive results, some of them in multiple parameters. For example, some lost weight and increased their flexibility, alleviating long-term aches. Some experienced an improvement in family morale or relationships because of their increased outdoor activities.

To tally up more steps, participants would opt to walk from work site to work site rather than use carts or bikes. They would take the stairs instead of using elevators. Many became more conscious of their diet and began eating more nutritious foods to augment their increased physical activity.

Over the nine-month challenge, 17 employees logged 55,308,557 steps—or 27,654 miles. This is equivalent to walking around the globe at the equator plus taking an additional trek across America.

Ferndale is a 2 × 1 7EA-powered combined cycle owned by Puget Sound Energy, operated by NAES Corp, and managed by Tim Miller.

HRSG, HEP improvements dramatically reduce EFORd

The Syracuse V64-powered 1 × 1 combined cycle, owned by Starwood Energy Group Global and operated by NAES Corp, typically has had an annual net capacity factor of less than 10% since COD in 1993; thus, it’s important for the plant to start when dispatched.

Over the years, the HP superheater has experienced three tube failures at the outlet of the upper distribution header, the last one in June 2016. The latest forced outage required 70.5 hours of downtime, which pushed the plant’s EFORd, or effective forced downtime rate, to over 10% for the year. To mitigate the potential for future forced outages, contractors were hired to inspect both the HRSG and high-energy piping (HEP). Here’s what they found:

-

- Three adjacent tubes in the superheater had suffered similar failures, indicating there was a recurring problem.

- One nozzle on the HP attemperator, and a pipe weld, had failed.

- Pipe hangers and supports were not properly supporting the steam lines.

The inspections were thorough, enabling staff to identify the root causes of the problems identified, thereby avoiding quick fixes that might not address the underlying issues.

The HRSG inspection pointed to undrained water in the lower header as the cause of HP superheater tube failures. This was attributed to a flow restriction at the point where the three ¾-in. header drain lines from the A, B, and C sections of the superheater combined into a single ¾-in. pipe. Relatively simple fix after making some calculations: The downstream ¾-in. pipe was replaced with a 1-in. pipe to facilitate drainage.

In addition, thermocouples were installed on the superheater drain pipes inside the HRSG. Now, when the control room operator notices a step-change increase in the drain-pipe temperature, he alerts the outside operator to begin closing the drains. The plant modified its startup procedure to capture this process.

To address the HP attemperator problem, new nozzles were installed and an additional collar was added on the attemperator pipe as specified in the new design drawings. Staff also set up a recurring PM work order to inspect the attemperators semiannually.

The HEP support issues required a simple, straightforward improvement. Plant installed new hangers and clips and added an additional support for the main HP steam pipe. Hangers also were replaced on the sagging NOx steam header, raising it 1¾ in.

As a result of these improvements, Plant Manager Steve Reinhart said the unit did not have a single forced outage attributable to a superheater tube leak in 2017, and the EFORd dropped to less than 4%.

Locating the source of moisture found in a transformer bushing

During a scheduled maintenance outage at Walton County Power, owned by Mackinaw Power and operated by Cogentrix Energy Power Management, power-factor testing for one of the generator step-up (GSU) transformers produced abnormal readings. To further investigate the problem, a dielectric frequency response (DFR) test was performed and concluded that the GSU’s H0 bushing had high moisture content.

Visual inspection of the bushing found that the gasket on the oil-fill plug was cracked. Over time, moisture seeped through the gasket, saturated the cellulose insulation, and caused the bushing to fail the test, requiring its replacement.

The cost of the bushing replacement and conditioning of the GSU oil was approximately $30,000. To avoid further bushing failures, two things have been added to the plant’s transformer test procedure:

1. A more extensive visual inspection of moisture vulnerable areas. Gaskets will degrade over time and are very inexpensive to change.

2. Use of DFR testing to check for moisture in the cellulose insulation through multiple simultaneous low-frequency tests. According to Megger (the company), typically 99% of the moisture in a transformer resides in the cellulose insulation, not in the oil. The DFR testing provides a way to trend insulation moisture content in the plant’s bushings and transformers.

Visual inspections during testing of other transformers since the bushing replacement have identified more cracked gaskets on bushing oil-fill plugs. By replacing gaskets that cost pennies, staff has helped extend the life of the bushings and avoid costly, unplanned repairs.

Improved oil-drum handling practice mitigates safety, health risks

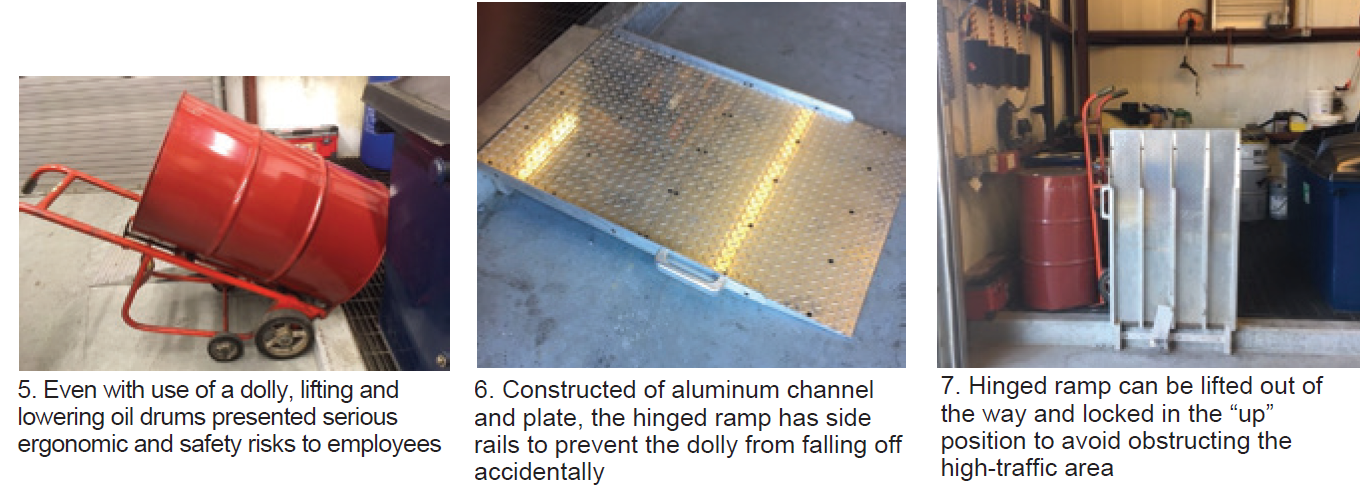

Oil-drum receiving and distribution at Wolf Hills Energy, owned by MPR Genco and operated by NAES Corp, required lifting and transport of heavy drums, which presented an ergonomic risk, as well as a safety risk, to plant personnel. To move a drum into the storage/containment area, staff would place the drum dolly on the lip of the containment area, then lift it into place (Fig 5).

To remove drums from the area, they would roll the dolly off the grating and, if wheels were not perfectly aligned when the dolly left the edge, it would destabilize the drum, forcing the handler to twist in order to correct the weight imbalance, possibly incurring a strain or sprain.

After studying the situation, Plant Manager Michael Beverley and his team came up with a design for a hinged ramp, which was then fabricated. It allows offloading and loading of the drums into the storage area without ergonomic or safety risk (Fig 6).

It was constructed of aluminum channel and plate, making the ramp light enough to lift easily when not in use and avoid obstructing the high traffic area. The Wolf Hills team also provided side rails to prevent the dolly from rolling off the ramp (Fig 6) and designed a locking mechanism to hold up the ramp when not in use (Fig 7).

The team’s solution answered all of the plant’s needs:

-

- It reduces the ergonomic and safety risks associated with transporting the heavy, unwieldy drums yet allows free flow of traffic when not in use.

- It is strong enough to serve the purpose, yet light enough to be easily lifted; the locking mechanism prevents accidental lowering.

Reduce iron content of wastewater to allow unrestricted discharge

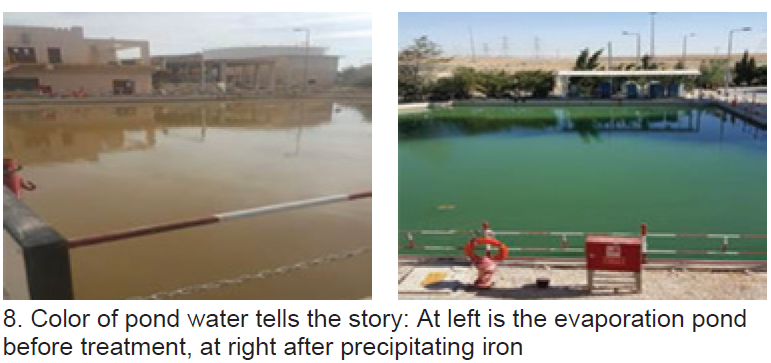

Iron in plant wastewater, attributed to HRSG tube leaks, exceeded permit limits at AES Jordan PSC’s Amman East Power Plant, a 420-MW 2 × 1 combined cycle. Unable to discharge water as is, the only viable solution appeared to be use of so-called authorized discharge tankers. But given the large volume of water, the cost of disposal would be prohibitive. Station personnel, led by Plant Manager Peter Kuijs, dug into the literature and found a technique for precipitating the iron to the bottom of the evaporation pond.

The precipitation reaction requires addition of trisodium phosphate and sodium hydroxide, plus lime to raise pond water pH to 8 to speed coagulation. The chemistry is relatively simple: Ferric ions combine with phosphate to form ferric phosphate which can be mucked from the pond.

Equipment required for the chemical reaction is standard and relatively inexpensive: dissolving tank, electrical agitator, chemical transfer pump, and associated piping and mixing nozzles. Treating in the evap pond the equivalent of a tanker batch of wastewater costs about 10% of what transportation and offsite disposal would have been.

The precipitation process has met expectations at affordable cost (Fig 8). No water has been discharged from the plant with iron above the permit level.

In-house operator rounds tracking

Nevada Cogen, a 3 × 1 LM2500-powered combined cycle, had used a fee-based third-party software and hardware solution for years to capture and store operator rounds data. It worked well until support was necessary. Issues with this platform included the following:

-

- If a handheld device had to be replaced, the cost was substantial (more than $1500).

- If there were backend database or program issues, vendor support essentially was non-existent.

- Retrieving data was cumbersome and frustrating.

Solution for Plant Manager Howard Forepaugh and his staff was to use 7-in. Android tablets on rounds and Excel for data storage. Most tablets have Excel or a compatible program pre-installed, and the unit cost (around $250) is significantly less expensive than the third-party device.

On the company server, Excel rounds were created with macros to automatically retrieve data from the tablets. The simplicity of using this solution allows for greater customization and doesn’t require outside contractor support if issues arrive. Using the data for trending is simple and the information readily accessible.

The tablets have been used for more than three years with positive results. There have been no problems with data corruption or loss, and the tablets are much more user-friendly than the earlier handheld device.

Fuel-flexible burner reduces aux-boiler O&M cost

AES Levant, a 250-MW Jordanian generating station powered by 16 reciprocating engines, was designed to run at peak load on natural gas, light fuel oil (LFO), or heavy fuel oil (HFO). The plant’s purchase power agreement requires the facility to be available to operate on any of these fuels at any time. This means heat always must be maintained on HFO tanks and pipes.

Two LFO-fired auxiliary boilers were provided to supply the heat required to maintain the HFO system ready to operate when the plant was not producing power. Plant staff was challenged to reduce the cost of using expensive LFO as a boiler fuel.

Project personnel, led by Plant Manager Peter Kuijs, identified and evaluated three possible solutions:

1. Insulating some lines and tanks.

2. Burning HFO in the boilers rather than LFO.

3. Replacing the burners with dual-fuel burners capable of firing natural gas or LFO. At the plant location, gas was less than half the cost of LFO on a heating-value basis.

A standard four-box evaluation matrix was established with “effort” along the horizontal axis and “impact” on the vertical axis. The engineering team found the third option as requiring the least effort and having the greatest impact.

Equipment specs were developed in-house and a burner that met the plant’s requirements in terms of compatibility and cost was identified. The project was completed two weeks after contract signing; performance tests were completed successfully.

This was an extremely worthwhile project from a financial and operations perspective. The cost of the burners was $72K and the fuel saving was $93K from August (when the burners were installed) to year-end 2017—a payback of less than five months. A saving of $170K was forecast for 2018.

CHP generates electricity, melts snow for muni

This could be every CCJ ONsite subscriber’s Best Practice: Replacement of a half-century old coal-fired unit with a modern combined-heat-and-power system powered by late-model gas turbines. Here are the details:

The city of Holland’s 60-MW coal-fired generating station, built in 1939 along the city’s waterfront, was not able to meet the municipality’s growing demand for electrical energy and for the thermal energy required by its expanding snowmelt system.

The Holland Board of Public Works (HPW) initially considered modernizing the facility, but there was no support for more coal power at the state level. However, it was important to maintain the underground snowmelt system, which serves about 13 acres of downtown sidewalks and roads.

The region experiences an average annual snowfall accumulation of over 70 inches. Use of snowplows, trucks, and salt for snow and ice removal is a considerable expense with some undesirable side effects—including pavement wear and tear and the negative impact of salt runoff on water quality.

In 2011, Holland conceived an innovative Community Energy Plan to provide a guideline for securing a reliable and independent power supply far into the future. Consequently, when planning for a new power station, HPW took into account environmental, health, and social implications as part of its Sustainable Return on Investment analysis.

The city, Siemens, and several design/engineering firms teamed up to develop a sustainable, fuel-efficient powerplant that uses natural-gas-fired combined-cycle technology. The result was a cost-effective and efficient solution.

Two Siemens SGT-800 gas turbines power the combined cycle. A side stream of circulating water exiting the condenser serving the SST-400 steam turbine is pumped into the city’s snowmelt system. The water leaves the plant at approximately 95F and returns at about 75F—enough thermal energy to drive a heat pump at the plant for building heat.

The CHP plant produces 125 MW of electricity in summer and 145 MW in winter while reducing CO2 emissions by 50% and virtually eliminating emissions of solid-particle pollutants.

Holland has the largest snowmelt system in the US. It is capable of melting one inch of snow per hour in ambient temperatures of 15F to 20F.

Holland Energy Park, directed by Plant Manager Dave Koster, is a world-class power generating plant, complete stunning architecture, a visitor center, and walking trails—a landmark for residents and tourists. It received the first ever Envision® Platinum designation for a powerplant from the Institute for Sustainable Infrastructure.

Plant attributes that helped city officials drive the migration to the cogeneration system included the following:

-

- Reduced fuel costs using less expensive (than coal) natural-gas supplies.

- Increased revenue from the expanding industrial consumer base.

- A revitalized downtown district that is accessible throughout the winter months.

- Holland expects the new facility will maintain the city’s 30% rate advantage to residential customers compared to competitor power producers.