Gas T

urbine Powerhouse

Development of the power-generation GT at BBC/ABB/Alstom

By Prof Dr-Ing Dietrich Eckardt

De Gruyter, Oldenbourg, 498 pages, $85

Reviewed by John F D Peterson

The fact that you are looking at this page in Combined Cycle Journal gives me high confidence that you are not only familiar with gas turbines but interested in them as well. If, from time to time, you also wonder how in the world these magnificent machines came to be. . . .then you are my target audience.

Gas Turbine Powerhouse is a story of heavy-duty gas turbine development and manufacturing from the point of view of Brown Boveri & Cie a/k/a BBC, a Swiss company that once stood foremost among the industry’s giants. Perhaps you have not heard of BBC; but if you are familiar with basic gas turbine history, or remember gas turbine fleets before 1990, then the name Brown Boveri is not new to you.

Some of you may even recall that in Neuchatel, Switzerland, in late 1939, the first gas turbine in power generation service began operation. That engine, designed and built by BBC engineers and technicians, is now an historical landmark, recognized in 1988 by the ASME and the Swiss Engineers and Architects Assn as the first commercially successful gas-turbine driven-power generation installation in the world.

The book follows BBC’s history of gas turbine development and manufacture from the early 1900s through the company’s official end in 1987 but includes substantial information on further development by its successor companies. These (at first a newly formed Asea Brown Boveri–ABB, followed by Alstom) continued to manufacture the engines with substantial technical innovation and improvements along the way. Anyone interested in gas turbine technology will benefit from this account.

For me, however, the greatest value of this story is the historical account of successes and failures, both within the company, and without, between the years 1900 and 1940. This period had been a mystery to me, and especially so because of my previous perception of the “sudden” appearance of an efficient axial compressor on the Neuchatel engine.

This magnificent component of turbomachinery, a high-flow, high-efficiency, axial air compressor, an indispensable part of every heavy-duty gas turbine operating in power generation today, didn’t just spring, fully formed, from its inventor’s head, did it? Well, no, it didn’t.

Around the turn of the century (1900-1906) Sir Charles Parsons struggled to develop an efficient axial blower for the purpose of coal mine ventilation. Both compression ratio and efficiency were very low.

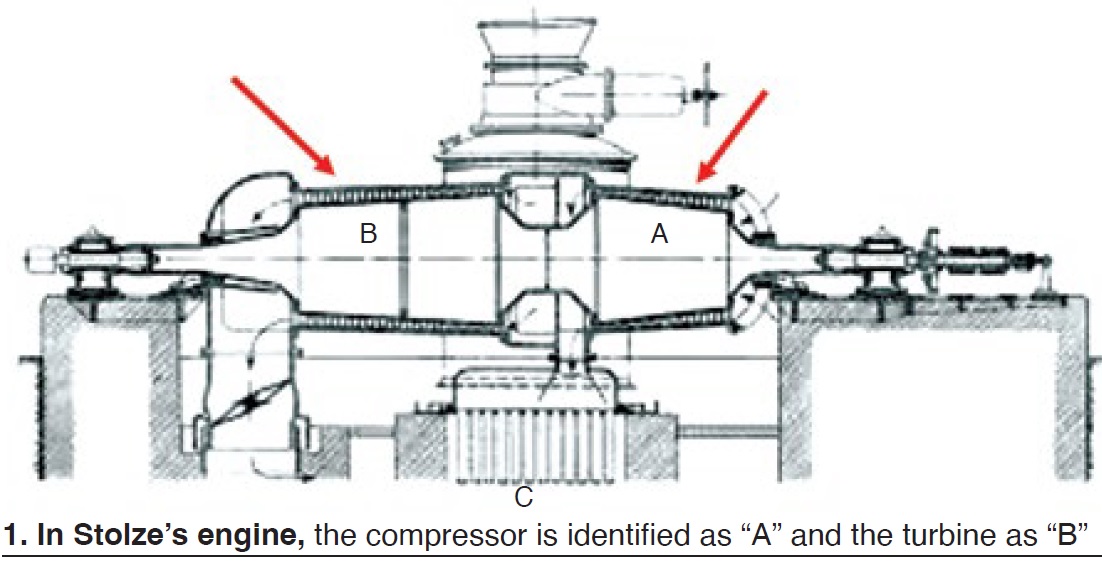

Another engineering pioneer of that same period, Franz Stolze, built an experimental gas turbine with axial compressor and axial turbine, but the combined inefficiencies of the two components prohibited a self-sustained operation of the engine. In the cross-section of Stolze’s engine (Fig 1) the compressor component is identified as “A,” and the turbine as “B.” One can see at a glance that the usual ratio of compressor stages to turbine stages, from, say, 5 to 1, or 6 to 1, is not followed, but is more the inverse. Nevertheless, this early experimental engine is ingenious, and has many familiar features found on successful gas turbines today.

Yet another interesting attempt in the first decade of the 20th century was the Holzwarth Explosion Turbine. This design avoided the need for efficient compression by using a repetitive sequence of confined combustion events. Low-pressure air from a blower was sufficient, along with injected fuel. Valves would open to admit the air and fuel to a chamber, then close to confine the combustion process within the chamber.

After each combustion event, a third valve would open, allowing the chamber of hot, high-pressure combustion gas to vent through a nozzle and bladed turbine wheel. These curious monstrosities actually achieved limited commercial success despite their single-digit thermal efficiency and complex machinery.

This obvious “work-around” used in the Holzwarth Explosion Turbine achieved through pulses of hot gas with a constant-volume combustion process what the “dreamed of” steady-state constant-pressure combustion process had been considered unable to do.

Whether known or unknown by Holzwarth and his team, a more conventional machine had already succeeded in achieving the steady-state, constant-pressure process several years before. Aegedius Elling, a Norwegian engineer, designed and built what many believe is the first truly functional, self-sustaining gas turbine in history. The year was 1903.

The engine used a six-stage centrifugal compressor, steam injection, and radial turbine to generate 11 hp. The fact that the compressor was of a centrifugal design instead of axial does not take away from the magnificent achievement of this gas turbine pioneer.

Elling continued developing his concept with a recuperated engine producing 75 hp, but for some reason ceased his experimentation a few years later. His farsighted intuition is revealed in these two predictions that he made in those early years of gas turbine technology:

- There was no practical reason why a gas turbine might not make a million horsepower.

- The gas turbine engine could be a made-to-order aircraft powerplant.

I do wish I knew more of Aegedius Elling and his work. For some reason, many histories neglect even a mention of Elling, and Gas Turbine Powerhouse commits only a paragraph to his work. Nevertheless, despite the lack of attention to this Norwegian engineer’s contributions, I consider Elling’s 1903 engine to be properly described as the first functionally successful gas turbine in history.

Three years after Elling’s initial success, two Frenchman, Charles Lemale, and Rene Armendgaud, built a much larger engine using a Brown Boveri 25-stage, multi-casing, centrifugal compressor, one of the world’s largest at the time. With steam injection, and a water-cooled, two-stage “Curtis wheel” turbine it produced about the same power as Elling’s, at an efficiency estimated to be 2% to 3%.

The story continues through the second decade of the 20th century with improved Holzwarth Explosion Turbines, and the introduction of turbochargers for various applications. Rapid development of these two product lines (particularly the turbocharger) led eventually to the Velox boiler after 1930.

These are especially interesting since they bridge the gap between the Holzwarth success and true constant-pressure gas turbines. BBC intended the Velox boilers to be capable of a high steam output for their size (think locomotives and marine applications), with the ability to start and ramp up quickly.

The Velox concept utilized high-pressure combustion in reinforced furnace structures, resulting in very high volumetric heat release. Energy recovery from the high-pressure exhaust gas, via a turbocharger, boosted the combustion air pressure, reducing (or eliminating) input horsepower for the forced-draft fan. Functionally these Velox boilers were gas turbines producing steam.

At this point, if you are still reading, you wonder: “Well, great! But what about axial compressors? Where did the Neuchatel gas turbine’s air compressor come from?” This, as you recall, was my own question from the very start, and here Gas Turbine Powerhouse began to deliver. It turns out that most Velox boilers, after about 1933, utilized multi-stage, axial flow compression and expansion in the turbocharger pairing.

Even more astounding, in 1934, another BBC project included a 13-stage axial compressor for supersonic wind tunnel testing at an aeronautical research facility in Zurich. I know I am running out of room to write, but I will also mention BBC’s Mondeville 10-stage test compressor rotor, complete one year earlier (1933), the first commercially available axial compressor in the world, with a pressure ratio of 2.6 and an adiabatic compression efficiency of 83%.

These revelations push axial-compression R&D efforts at BBC into the mid to late 1920s, earlier than I would have ever imagined before reading this amazing story. One ingredient in BBC’s formula for success regarding axial compression was the introduction of airfoil theory. This factor had been unavailable (and unknown) to the earlier pioneers of turbomachinery leading to their ultimate lack of success, notwithstanding their otherwise ingenious inventiveness.

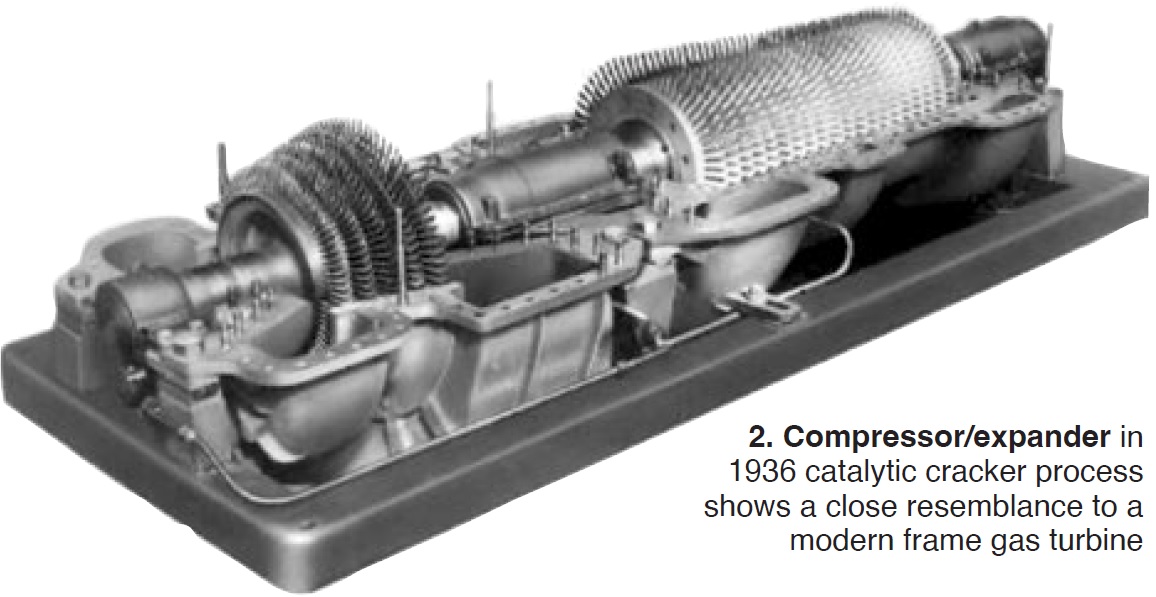

Leaving wind tunnels and Velox boilers behind for a moment, I must mention one more surprise in the BBC story during the pre-war period of axial-compressor development, and one much closer to home. In 1936 the first commercial operation of a fixed bed catalytic cracker for petroleum refining began operation at the Sun Oil Refinery in Marcus Hook, Pa. This was the Houdry Process, named for its developer, Jules Houdry, and the heart of its gas circuit was a gas expander, and air compressor. Fig 2 shows the combined unit on the half shell.

Doesn’t this look a lot like a modern heavy-duty gas turbine? In fact, it is by anyone’s measure a genuine gas turbine, with axial compressor and turbine. The combustor was the catalytic cracker itself. Apparently, also attached to the machinery string was a generator to make electrical power from the excess shaft power.

Move over Neuchatel, here is another heavy-duty gas turbine “first” to command a share of our admiration!

Several names stand out during this period of axial-compressor innovation at BBC: Jean von Freudenreich, Georges Darrieus, and Claude Seipple. This last individual was a 28-year-old just back from an assignment in the US. Herein lies a mystery, and one as-yet untold in the story. The young engineer/inventor, Seipple, returned to Baden in 1928 and became a very important figure in BBC’s axial-compressor development as well as in Germany’s axial flow aircraft engine development.

The author of Gas Turbine Powerhouse promises the rest of the story in a second book, Jet Web, which I just received. It too is available at Amazon. Be looking for another book review sometime soon to learn the rest of the story.

John F D Peterson, who graduated from Georgia Tech in 1970 with a BS in Chemical Engineering, recently began his 53rd year as a process engineer at BASF’s Geismar (La) chemical production site. Although retired as a direct employee of BASF, he continues part-time as a contract engineer in the company’s Utilities Dept. Plus, he provides troubleshooting, training, and performance assessment/optimization services to gas-turbine owner/operators nationwide.