The annual Combined Cycle Users Group (CCUG) conference and vendor fair, held in Louisville, Ky, Aug 27-30, 2018, proved once again to be an excellent barometer of what’s on the minds of those charged with making sure gas-fired combined cycles (CCs) start and stop when they are supposed to, make money for their owners, and attain or surpass the performance metrics expected of them.

Among the broad themes you’ll take away here:

-

- Staffing and expertise issues continue to plague the industry, especially OEMs.

- Need for flexible systems grows, as do the maintenance consequences of greater cycling imposed on plants not designed for it.

- Impact on existing facilities of the latest H and J machines coming online, as well as early storage units, is imminent. These new GTs are nimble and several percentage points more efficient than predecessor models. Batteries can, theoretically, respond for grid services close to instantaneously.

- Shift in regulatory burden from environmental to physical and cybersecurity.

The staffing issue was aired right out of the gate by the regional utility executive who kicked off the opening plenary session: “We’re about to lose 40% of our generation staff; while contractors are filling in, there’s a real skills gap.” More than one presenter lamented about the man-hours required to deal with NERC issues, yet another burden on already-lean staffs.

To dig deeper into the topics summarized here, access the meeting presentations on the Power Users website. If you’re an owner/operator and not registered to use the group’s library, sign up today online. Recall that Power Users is the umbrella organization for managing and coordinating the technical programs for the industry’s leading user groups—including 7F, Combined Cycle (CCUG), Steam Turbine (STUG), Generator (GUG), and Controls (PPCUG).

Highlighted plants

Some of the first Mitsubishi J-class gas turbines are now in early commissioning at a 2 × 1, 925-MW site, one of several new power stations equipped with the latest and largest GTs. According to the presenter, the J machine features a 5800-Btu/kWh heat rate in CC mode, and 63% cycle efficiency. Plant will run “totally merchant” at an expected capacity factory of 85%. Each unit can achieve 50% load in 30 minutes.

Somewhat astonishingly, the plant, once it goes commercial, is planning only one outage late in 2019 “to get warranty claims done.” That performance goal was even more stunning after hearing that “the OEMs and EPCs lack expertise with these machines, their outages, and the models used to control them.”

About 80% of the plant’s staff comes from coal-fired plants, as there is little gas-turbine experience available in that region. More than 500 resumes were received for 19 hourly positions, 24 total. “Everyone must be cross-trained,” the presenter said, implying that the staff is beyond lean, and “the plant manager is responsible for training, especially training hourly employees to be managers.”

In that vein, most of the presentation was focused on intensive training to recruit and retain employees even at the risk of losing them to the plant down the road. “The only thing worse than training employees and having them leave is not training them and having them stay.”

GTs + storage? One conclusion you might draw from a presentation on a UK facility is that the next asset plopped down at your CC may not be a GT, but a storage unit instead. According to this presenter, such a hybrid plant can meet all grid services—frequency response, spinning reserve, black start, energy arbitrage, and voltage regulation, as well as earn payments in the capacity market.

This five-year-old 1300+ MW, 3 × 1 facility added a 49-MW battery which started operating in the first quarter of 2018. The first revenue stream derives from delivering near-instantaneous response to frequency changes. Winning in the capacity-market auction provides a second revenue stream. Salient features of the battery: 34 MWh stored energy, 20-year asset life (battery cell replacement at 10 years), and 20 containers totaling 150,000 lithium-ion cells.

Lest you think adding storage to gas-fired plants won’t happen here, recall that the whole “dash for gas” originated in the UK in the early 1990s. Also, as the presenter mentioned, FERC 841, “Electric Storage Participation in Markets Operated by Regional Transmission Organizations and Independent System Operators” came out earlier this year, essentially intended to create a level playing field for storage assets in regional US electricity markets.

Outage best practices

One of the most enlightening items, coming under an informal session titled “Best Practices for Outages,” is the existence of the website, ISNetworld. Perhaps it is better placed under the heading, “the world is fully knowable” (at least on the Web).

ISNetworld, launched in 2001 with process industry clients as early adopters, is a source for managing contractors from one location. Like similar sites which aggregate performance data from facilities and redistribute it to the participants, this one aggregates reported information on contractor performance. Apparently, you can review stats, monitor performance, and research contractors before they are selected or show up at your site. From the website: “By collecting and reviewing safety, insurance, and regulatory information, ISNetworld streamlines the contractor qualification process for 550 hiring clients worldwide.”

Other outage best practices noted during the session included the following:

-

- Warn contractors that nothing goes down the plant drains.

- Add 480- and 220-V receptacles (drops). Plants often are deficient in drops to minimize the installed cost.

- Add 480-V heat-trace panels in cold-climate locations.

- Map out laydown and layout spaces before the outage begins.

- Badge each contractor, and monitor and track them.

- Avoid background checks at low-impact NERC CIP facilities.

- Add physical security at the plant entrance. One site was said to employ a local cop—appropriately armed so he doesn’t get any lip.

Discussion topics

The open-discussion sessions at CCUG the last few years have featured a padded wireless mic “cube” tossed to the next person who wants to add to the discussion. The moderators are practiced at the toss, based on the accuracy of their throws. Here’s a punch list of topics, generally arranged in order of the animated discussion around them:

Attemperator inspections and frequency. One attendee said that this is one of the toughest services in the whole facility and few undoubtedly would dispute that claim (see below). One attendee with a “high-cycling probe-type attemperator” said they inspect it every two years. A second described a failure on the attemperator line at the sleeve, the root cause was leak-by. “It doesn’t take much water to cause stress and shock,” he said. A third said they had had poor experience with one OEM’s design. Remedies include revisions to the control logic to reduce attemperator cycling, doing external spray tests to check the spray pattern (only a few raised their hands to indicate they did this), and use of a specially designed rig offered by Fisher Valves & Instruments to do the spray tests.

HRSG liner failures/liberation. One attendee said his plant had significant HRSG liner failures in the first year of operation, and another responded that he’d been “dealing with this his whole career.” The liners are held in place by studs which tend to fret and fail from flow energy vibration. If this leads to cracks in the casing, you may experience problems with steam drum supports, he added.

Software/hardware for operator rounds. This essentially was a discussion about replacing paper with digital records; responses were all over the map. Several commercial products were mentioned, including RoundsKeeper (Instamation Systems), MAINTelligence™ (DMSI-Design Maintenance Systems), and eLogger (eLogger Inc). If you are gearing up for the switch, know that one plant rep said it “took months” to go from paper to electronic and another said it took a year. A few of the interesting comments include: “ledger books are no longer used at our plant, “we don’t have enough people to take reams of data by hand,” “even though we have electronic records, we still keep hard copy logs,” “we stress the training value of what the operators log,” and “still need operators to see and hear the equipment.”

Welding issues with P91. This is a perennial topic at this forum, and many others. One attendee cautioned that most of the P91 components come from Asia and you need to add hardness strength in the formulation to compensate for later repairs. Another attendee noted that you can weld repair P91 twice before you have to replace it. A third said his company had developed a qualification procedure for onsite welding of P91.

Obsolete equipment. A facet of the discussion addressed the fact that OEMs declare components obsolete when that may not be the case. One plant rep lamented that they had “lots of obsolete stuff even after only 13 years.” Control system software and hardware seemed to be a category unto itself. Another thread in the discussion was having spares in inventory. “Things can break when you do an upgrade,” someone said. And then a word of advice: “Replacing obsolete components requires management of change documentation!” Most plants probably wished they had this option, uttered by one attendee: “Declare it surplus and have purchasing handle it.”

Leaks from the top of HRSG casings. The discussion began with infrared (IR) thermography surveys, one attendee noting “from top to bottom.” Another said they use contractors for IR surveys but that “you have to work with them for HRSG roofs.” A third attendee pulled no punches: “HRSG designs are crap. They catch water, they have no railings, they pose all kinds of safety issues.” Another noted that you have to be a contortionist to access for welding repair. Be aware that it’s sometimes hard to see cracks as they can “seal up in cold weather” when materials contract.

Under–insulation corrosion. Most of this discussion centered around identifying problem areas in piping and vessels using an eddy-current “lite” program to “semi-quantitatively assess wall thickness through 8 to 10 in. of insulation for main steam piping lines. Because the technique does not distinguish between outside and inside loss, you have to follow up with a magnetic-flux leakage inspection technique to measure loss. The EC-lite technique helps avoid stripping insulation in places with no loss.

Film forming amines. The question was, is there any impact on the steam turbine when this technique is used to reduce iron transport? One respondent who had looked into this answered that they had found no impact.

Desuperheater replacement. A plant rep who described replacing one manufacturer’s unit with that from another vendor reported performance was good but that they experienced packing leaks. They also relocated the positioners outside of the enclosure so they would not overheat and technicians could work on them more comfortably.

NH3 injection-grid mods. A California plant re-engineered the vertical manifolds by drilling extra holes on the edges to redistribute flow while plugging other holes. This reduced ammonia slip from 5.2 to 1.8 ppm. The original grids were not properly designed, the rep said, and that you need a system perspective to properly address SCR issues.

Remotely monitoring HRSGs and ST/Gs. One rep for a third-party operator said they had partnered with a consulting firm for daily monitoring and management of “PI points,” but that it was not real-time. Another referenced the owner’s remote M&D center staffed by two analysts who look at the data and hold weekly calls with the plants. “Most of what is caught are instrumentation issues,” he stated.

Online leak testing. One plant rep said they are doing this quarterly because “they find problems routinely.” Another said their company protocol was annually.

Human performance

Gas-turbine sites at one utility are participating in a company-wide human-performance initiative (HPI) to make reducing or eliminating human errors and organizational process shortcomings part of the company culture, much like safety programs. The rep noted that a study of “significant events” showed that 80% are caused by human error, and only 20% are because of equipment issues. A significant event is a forced outage, a derate of more than 20%, or a reportable safety or environmental incident.

Although no direct link to staffing and expertise was made in this presentation, it is clear that an HPI program can go a long way towards ensuring that plant personnel are properly trained and experienced and work processes don’t fail them.

Valve erosion

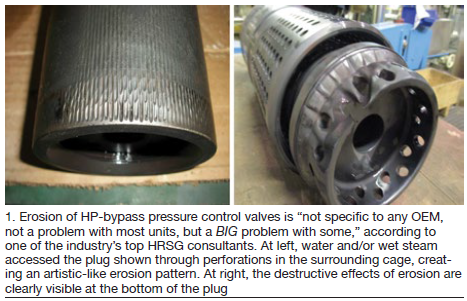

A renowned HRSG consultant tackled HP-bypass pressure-control-valve (PCV) erosion (Fig 1), opening his talk with “none of these valves can survive if you put water through them.” Magnetite entrained in the water, picked up in idle piping lines, will increase the erosion rate a hundredfold. Once erosion occurs on the plug and seat, steam will leak, overheating the downstream carbon steel pipe.

He offered three case studies, the first in which the HP-bypass PCV began leaking through after only a couple of early runs, although he conceded the plant endures some unique operating modes. In the second case study, leakage began in less than two years of operation, despite valve modifications to arrest erosion. In the third case study, it was discovered that the valve was opening at the wrong time in the start sequence.

“The bypass lets you control the ramp rates, but erosion and subsequent leakage is the probable consequence,” he stated. The presentation wrapped up with this question: Are there alternative methods of depressurizing under bypass conditions? An idea tossed out for discussion was an additional bypass around the original HP steam turbine bypass designed for mixed flow.

Attemperator failure analysis

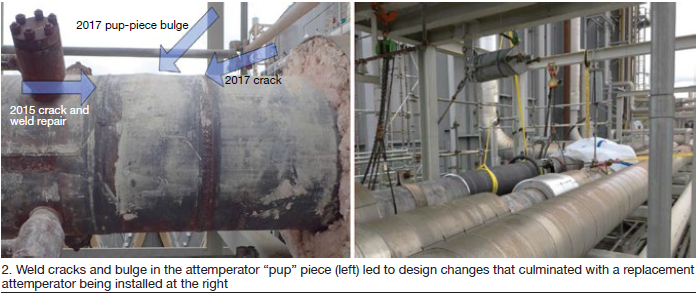

A rep from a 1 × 1 CC in the western US delivered the type of presentation attendees come to CCUG for: A detailed, richly illustrated (Fig 2) root-cause analysis of a hot-reheat final attemperator which failed twice, once in 2015 and again in 2017. Providence kept this from becoming a catastrophic failure event.

After reviewing the commercial and operating history of the plant, the presenter told how a foreman was milling around and saw steam pouring out of the main-steam-line lagging. Taking the plant down and removing the insulation revealed a bulge at the top of the attemperator “pup” piece (a length of Sch-60 straight pipe welded to the attemperator piece and the P91 main steam line) and a 4-in crack.

After reviewing the commercial and operating history of the plant, the presenter told how a foreman was milling around and saw steam pouring out of the main-steam-line lagging. Taking the plant down and removing the insulation revealed a bulge at the top of the attemperator “pup” piece (a length of Sch-60 straight pipe welded to the attemperator piece and the P91 main steam line) and a 4-in crack.

It turned out that the attemperator had no liner (thermal sleeve); it was significantly oversized, along with the temperature control valve; there were pipe support issues; the post-weld heat treatment (PWHT) was too long and violated code; the original Type-422 stainless steel nozzles were replaced with Inconel nozzles; and metallurgical lab analysis showed that pipe cracking was caused by thermal shock.

A redesigned attemperator was specified with three nozzles rather than four and a body length of 9 ft instead of 3 ft (to eliminate the pup piece and reduce the overall number of welds). All piping with PWHT was removed and replaced. Unfortunately, two years later, weld failures recurred. After grinding out the area and weld repairing, staff began to get concerned about the number of heat treatments and creep life.

A third ring-type attemperator replacement was specified and installed during an outage this year. Even during this work, issues arose with prolonged PWHT, purge dam failing, coordinating large radiography test (RT) crews, and more weld failures prior to PWHT. This may be yet one more example of expertise issues plants are grappling with.

Such experience is common. The presenter mentioned another user he was familiar with which had five attemperator failures early on in plant operation. He offered these lessons learned:

-

- Health and safety. Hexavalent chrome may be present during grinding and welding.

- Involve site personnel in determining RT site exclusion zones.

- Maintain strict control over RT crews and schedule.

- Attemperator lead times are long; even an expedited delivery took 20 weeks.

- Limit P91 heat treatments to three or less.

- PWHT and welding of P91/F91 are poorly understood by many in the industry. Verify procedures!

- Hardness testing may not be accurate in predicting material condition.

- Have a contingency plan for purge dam issues.

- Problems maintaining vacuum will show up at the attemperator piping.

- There is value in performing pre-PWHT weld inspections.

Glycol sleuthing in cooling water

If you ever detect glycol odor emanating from your storm water drain, you might want to request this presentation from a plant in the northeast. After operators noticed the closed cooling water (CCW) system tank levels dropping (despite refills), and detecting glycol odor in the system (water/propylene glycol mixture), sampling at the stormwater drain and the downstream retention pond confirmed presence of glycol. Unfortunately, at this unit, around 3000 ft of the CCW piping is underground.

The situation turned into an environmental event: Biological oxygen demand (BOD) at the water discharge to the receiving body was permitted at less than 30 ppm, but the leaking glycol drove it two orders of magnitude higher.

Troubleshooting included walking down all the above-ground CCW piping and equipment, isolation of supply and return lines, acoustical analysis (not helpful), hydrostatic testing with pressurized air, and even invasive digging in the HRSG area. But the critical clue turned out to be that the CCW temperature was found to affect leakage rates; lower temperatures, less glycol.

By driving the temperature as low as it could possibly go, the plant located CCW fluid coming from the ground around the CW piping associated with the GT lube-oil cooler. Maybe you guessed it: The piping was located under the turbine floor. A 24-in hole was bored into the floor and the leak was discovered on the supply side of the cooler. The CCW system was taken out of service, a larger area of the turbine floor was removed, the entire system was drained and a permanent repair was made. All of the glycol-tainted pond water had to be treated as well.

Formal high-energy-piping assessments

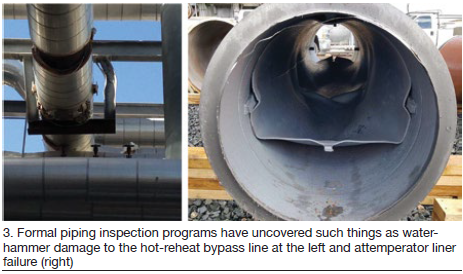

An attendee from one of the largest owner/operators of gas-fired power stations in the US described the evolution of his company’s centralized high-energy covered piping system (CPS) program, adhering to or exceeding ASME B31.1 Power Piping Code requirements. The program includes flow-accelerated corrosion assessments and NDE recommendations. Primary program elements include these:

-

- Baseline assessments conducted within three years of COD, preferably in the first year.

- Five-year follow-up hot and cold assessments of balance-of-plant, non-boiler external, and boiler external piping 2.5-in and larger (code requires 4 in. or larger); main steam, hot reheat, cold reheat, and boiler feed water; and piping that operates above 750F or 1025 psig.

- Annual O&M piping inspections conducted by plant personnel: Visual assessments from casing to casing—including piping, supports, and in-line components (flow meters, valves) for overall integrity, evidence of water hammer, improper slopes, etc.

- Each site has an assigned CPS program coordinator.

- Documentation includes just about anything that might impact the condition of the piping, from original P&IDs to records of transient events and operational data.

- Standardized reporting format using hyperlinks from spreadsheets (home-grown system).

- Consistency in selection and use of third-party contractors to perform the work.

- High stress areas for NDE assessments are prioritized.

- Subset, but separate, program for P91/Grade 91 components.

If you want to understand the value of such a formalized approach, look at the Fig 3 photos; they illustrate what you might expect to find during such assessments. By the end of last year, this owner/operator had conducted a baseline assessment and at least one follow-up assessment (five-year interval) of all plants in a fleet which includes 92 gas turbine/generators and HRSGs and 47 steam turbine/generators.

Vendor thumbnails

For those suffering with economizer issues, an HRST Inc expert told the audience about its Shockmaster® economizer, an all up-flow single-pass design that can be installed in two weeks or less. It solves the problem of pass-to-pass temperature differences. The first unit went into service in 2007 at a site experiencing numerous economizer failures. Since the replacement only one failure has occurred. Numerous other units have been installed since then.

HRST also offers its return-bend economizer support upgrade. Among the pearls of HRSG operating wisdom dispensed during the presentation were rapid cooling of steam drums does more damage than rapid heating; small numbers of cooler tubes among many hotter tubes leads to numerous failures; warped tubes can still last a long time; and economizer drains should be blown down at 50 to 100 psig once per month before the cold season.

AAF International explained its GT inlet heating system to expand the lower end of the GT operating range from 35% to 30% turndown and achieve greater flexibility. Heating the air intake by 24 deg C will improve part-load efficiency (though at the expense of an increase in parasitic load). Plants can avoid cold starts by remaining at the minimum emissions compliance level (MECL) for several hours or overnight. There’s a significant savings in fuel consumption, too. A two-year payback for the inlet heating system was reported by a plant in Italy.

A representative from Ansaldo Energia/PSM addressed plant needs for flexibility and optimization, and minimizing operator variability, with solutions that don’t require gas-turbine hardware upgrades. The company’s AutoTune product, which replaces the OEM’s tuning expert who typically shows up seasonally, can be used with Mark V and VI, TXP, T3000, and Ovation control systems. Importantly, it does not override the GT controller.

More than 50 Autotune systems are operating today, said the rep. PSM also works with Emerson, provider of the Ovation automation platform, to address balance-of-plant issues, new sensors, and valve response issues.

Siemens spent part of its allotted “Siemens Day” describing its exhaust-gas attemperator, which “decouples the GT from the steam cycle” if there is no bypass stack available. Simply, water or air is added into the exhaust which improves peak shaving, enhances cold-start performance and efficiency, decreases startup fuel and emissions, and enables GT operation above the limits imposed by the HRSG. Note that the water option will consume demineralized water and one attendee observed that care must be taken that no water impinges on the downstream SCR catalyst.

The physical configuration involves eight attemperators distributed along the circumference of the exhaust duct downstream of the thermocouples. Each attemperator has five water injector nozzles.

Both Siemens and GE, during each OEM’s respective session, emphasized system-wide optimization strategies and digital-based solutions. GE’s top service guys dwelled on FieldCore, their field-service company, described as a “work-in progress,” and a “massive new organization” intended to make up losses in revenue from new-build with field-engineering and outage-management services.

GE-supported options delineated to the audience included OpFlex AutoTune, Variable Load Path, and Turbomax for ST/G stress control automation. Most of these involve modifications, enhancements, changes, and/or refinements to the control strategies, hardware, and software.

Physical options, described in CCJ previously, include heating blankets and ST/G shell warming (with hot air, those units with double shell). Clearly, both behemoth OEMs are seeking to drive more revenue from facilities with performance consulting around enhanced monitoring, analytics based on digital software and new sensor technologies, financial and weather forecasting models, equipment health advisories, startup advisors, dashboards with key performance indicators, and digital “twins” (simulator capabilities to test and diagnose control strategies, anticipate issues, etc).