“Mastering Desuperheating and Attemperation,” Ory Selzer, IMI Insyt

Almost 200 slides long, this presentation could serve as a comprehensive training course on what can and does go wrong with two of the most vexing subsystems in the steam cycle, as well as solutions. Instructor sets the stage with numerous photos of component failures (Fig 6), then reviews function, theory, and fundamentals; available designs; most challenging designs; impacts from unit cycling; and two of the company’s attemperator solutions. Slides also cover turbine bypass systems (TBS) design, challenges, noise effects, TBS desuperheater applications, and solutions to common problems. Company has replaced over 400 attemperators in North America and supplies all the major HRSG vendors.

“LOTO Trap Roundtable Discussion,” Matt Barnes, MD&A

Outage work at legacy gas-turbine installations can be more prone to safety incidents because precautions and procedures may not have been updated over the years. This presentation opens with detailed safety incident report (lacerated finger in a rotating fan blade) from a 1975-vintage 7B gas-turbine site, a time when fan-guard maximum spacings were not published and turbine heaters were not part of LOTO if work was not scheduled in the area. The incident is well worth reviewing as a means of forcing evaluation of other potential situations in older plants. List of other “LOTO traps” is included.

“Turndown or Shutdown? Combating the Effects of Increased CCGT Cycling,” Jeff Schleis, EthosEnergy

Macro trends in renewable energy growth, electricity pricing, and CCGT capacity factors are reviewed, along with options and investments to extend turndown range and plant profitability. Results from a case study in Germany is included.

“Hydrogen as a Fuel for Gas Turbines in the Power Industry,” Gus Graham, CRDX-Carbon Reduction Systems

A useful table is provided showing firing characteristics for hydrogen/natural gas blends from 0 to 100% assuming a 7F.04 machine, along with basic information on H₂ properties, the H₂ “color rainbow” (the different sources and environmental attributes), and H₂ value chain. One useful fact on experience: One vendor reports that more than 100 gas turbines worldwide are now operating on H₂ blends.

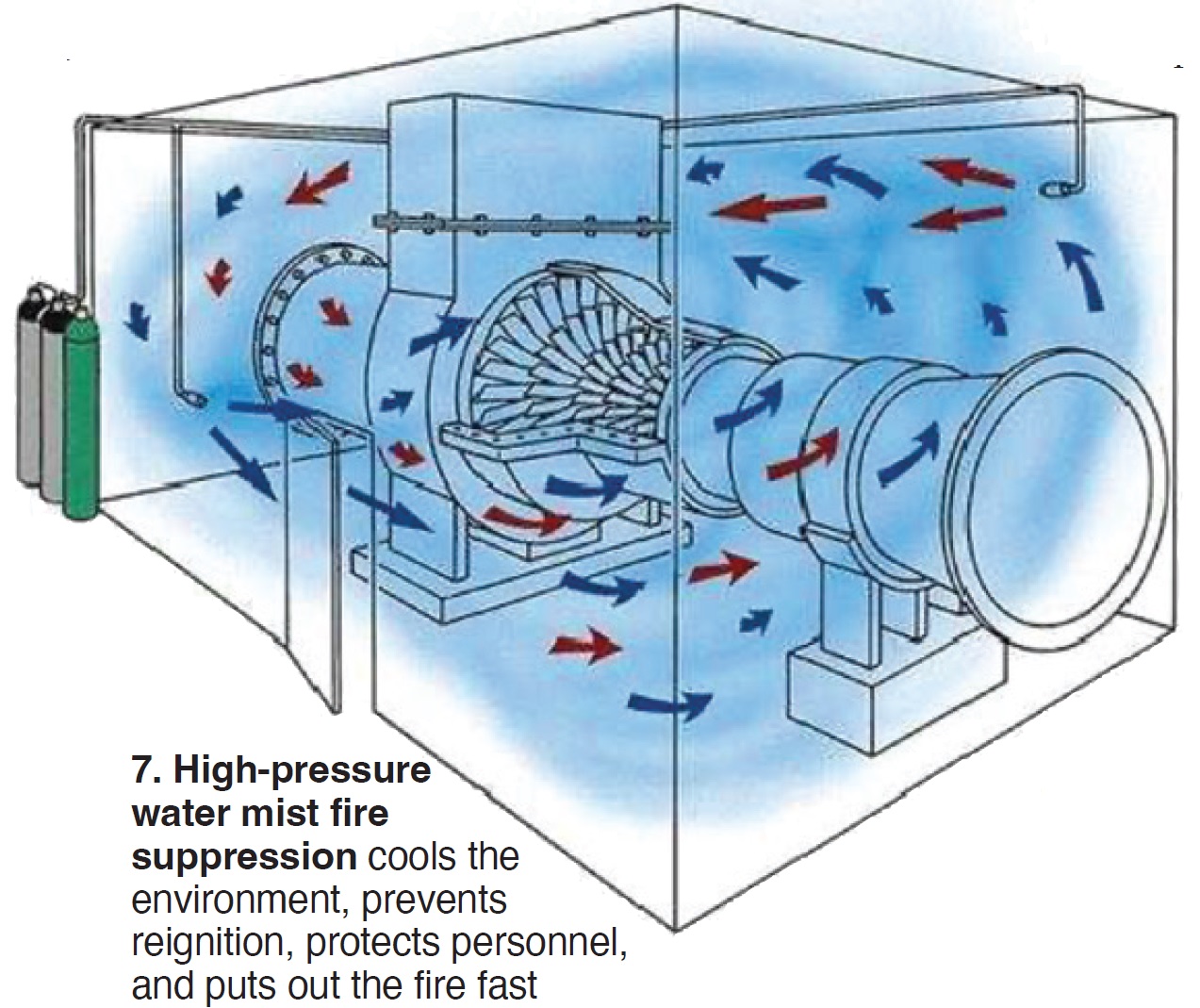

“Water Mist Fire Suppression System for Power Generation,” Jonathan Ingram, Marioff NA

Most everything you need to know about high-pressure water mist systems (Fig 7) as an alternative to low-pressure water mist, Halon, CO₂, dry chemical, and other options. One statistic (from a leading insurer’s technical report) that may may drive you to examine these slides closely: “A study of fire protection in gas-turbine installations reported a 49% failure rate for total flooding Halon or CO₂ systems…” One important advantage cited is that high-pressure mist is not compromised by an enclosure open door.

“Enhanced SCR and CO System Management for Today’s Operational Challenges,” Andy Toback, Environex

A variety of operating changes—among them high ammonia slip, CO catalyst behavior, turndown, and H₂ fuel blends—lead to high NO₂ emissions at the turbine exhaust. Bulk of the presentation addresses the impacts of this on SCR and CO systems, as well as general maladies affecting performance. Presenter advocates for full system analysis, including an engineer on site for inspection and sampling, testing multiple catalyst samples from each unit, and analyzing plant operating data.

“Process Chemistry in Combined Cycle Power Plants,” Andy Howell, EPRI

Textbook-like chapter in slides covers water chemistry and treatment for plants with water- and air-cooled condensers.

“Supply Chain Challenges 2023 and Beyond,” Bob Wasik, Voith US

Learn from company’s challenges and solutions in servicing torque converters and maintaining an exchange program to address your supply-chain issues. Two software platforms mentioned in the slides as contributing to company’s ability to manage supply are SAP and Microsoft Navision.

“HRSG Duct Liner Design and Installation,” Samir Baydoun and Bill Kitterman, SVI Bremco

Take a journey that includes a functional explanation of a duct liner, design parameters, failure mechanisms (replete with excellent photos), considerations for repair and replace decisions, and field construction (also with excellent photos).

“Gas Turbine SCR in the Changing World,” Dan Johnson, Cormetech

If you don’t need a primer in SCR function and design or gas-turbine market trends leading to increased cycling, start with slide 45, where you’ll learn about new catalyst designs you can consider if you need to add catalyst to further reduce CO and/or NO₂ or improve performance.

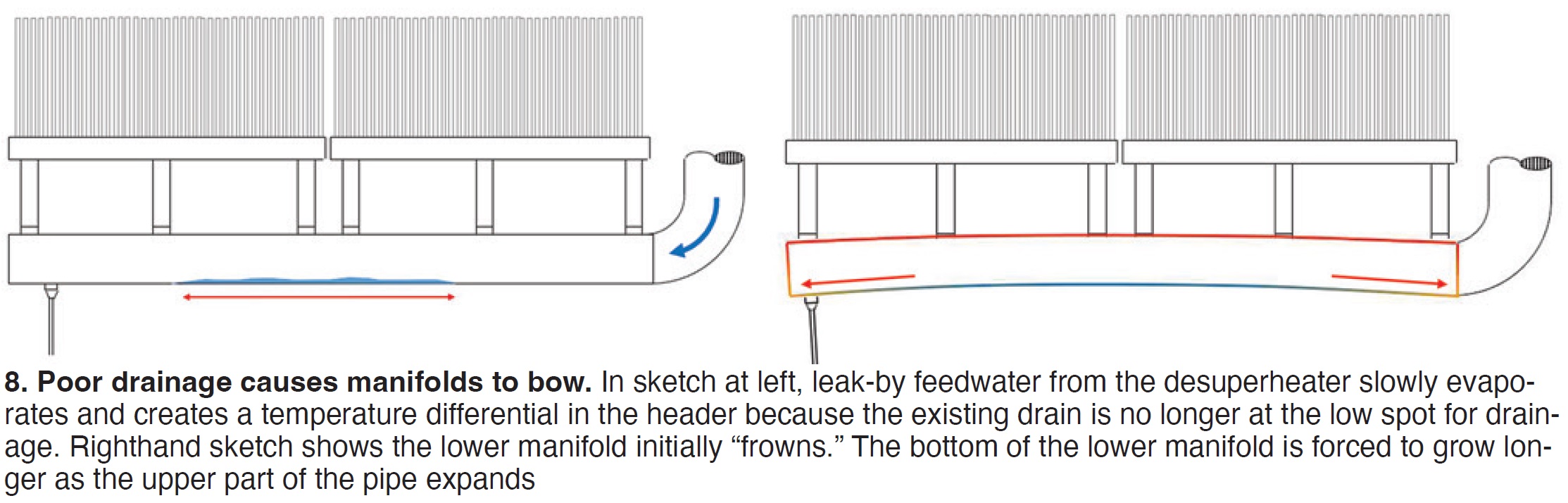

“Effects of Cycling Operation and Superheater and Reheater Link Piping and Manifolds,” Edgar Castro, HRST Inc

Presentation specifically covers inspection, maintenance, and redesign for what is described in the title for the Aalborg reheater tube panel and desuperheater (DSH) manifold and the Alstom superheater and reheat “straight shot” interstage DSH. Slides include clear and concise diagrams and excellent photos of damaged components (Fig 8).

“Duct Burner Issues and Flame Monitoring—Lessons Learned,” Lester Stanley and Anand Kumar, HRST Inc

Slides cover turbine exhaust-gas bypass affect on burners, structural failures in burners and potential retrofits, fuel-line corrosion and nozzle plugging, and flame-monitoring strategies and best practices. Regarding the latter, because burner problems can cause expensive, collateral damage, presenter advises you to “get familiar with your flames” by maintaining your viewports, correctly positioning them, replacing them with better designs, and/or mounting video cameras so flames can be monitored in the control room.

“Steam Drum Inspections,” Amy Sieben, consultant

Everything you always wanted to know about steam drums, first in generic terms, then by individual vendors Aalborg/CMI, Alstom, Deltak, Foster Wheeler, Nooter Eriksen, and NEM.

“Moving Goal Posts—What Is Insurance Looking for Now?” Chris Black, Lockton Companies

Presentations from Insurers tend to sober you up but this one may get you to quit drinking. Costs and allocations are escalating; market conditions are terrible; equipment normally not on the insurer’s radar, like steam turbine/generators and transformers, are experiencing more catastrophic failures; new gas-turbine models are problematic; business interruption is growing because of delivery delays; and climate change impacts are being priced in. And that’s just for starters. Some insurers are even developing their own GT equivalent operating hours calculations. Conclusion: Plants must objectively differentiate themselves to enhance their insurability.

“Detecting and Mitigating Damage In Attemperators/Desuperheaters,” Tom Sambor and John Siefert, EPRI

Relevant sections include diagnosing problems with historian data, attemperator diagnoses with additional instrumentation, mitigation strategies, and a bypass desuperheater case study including metallurgical analysis and findings, review of operating data, and recommendations. As routing data to the DCS/historian can be difficult, “EPRI has developed a low-cost solution for data collection and retrieval.”

“Header End Cap Failure Case Studies,” John Siefert, EPRI

Based on five failures occurring worldwide between 1991 and 2005 and a “recent” incident at a coal-fired plant, EPRI recommends that plants institute an integrated life-management plan for this component.

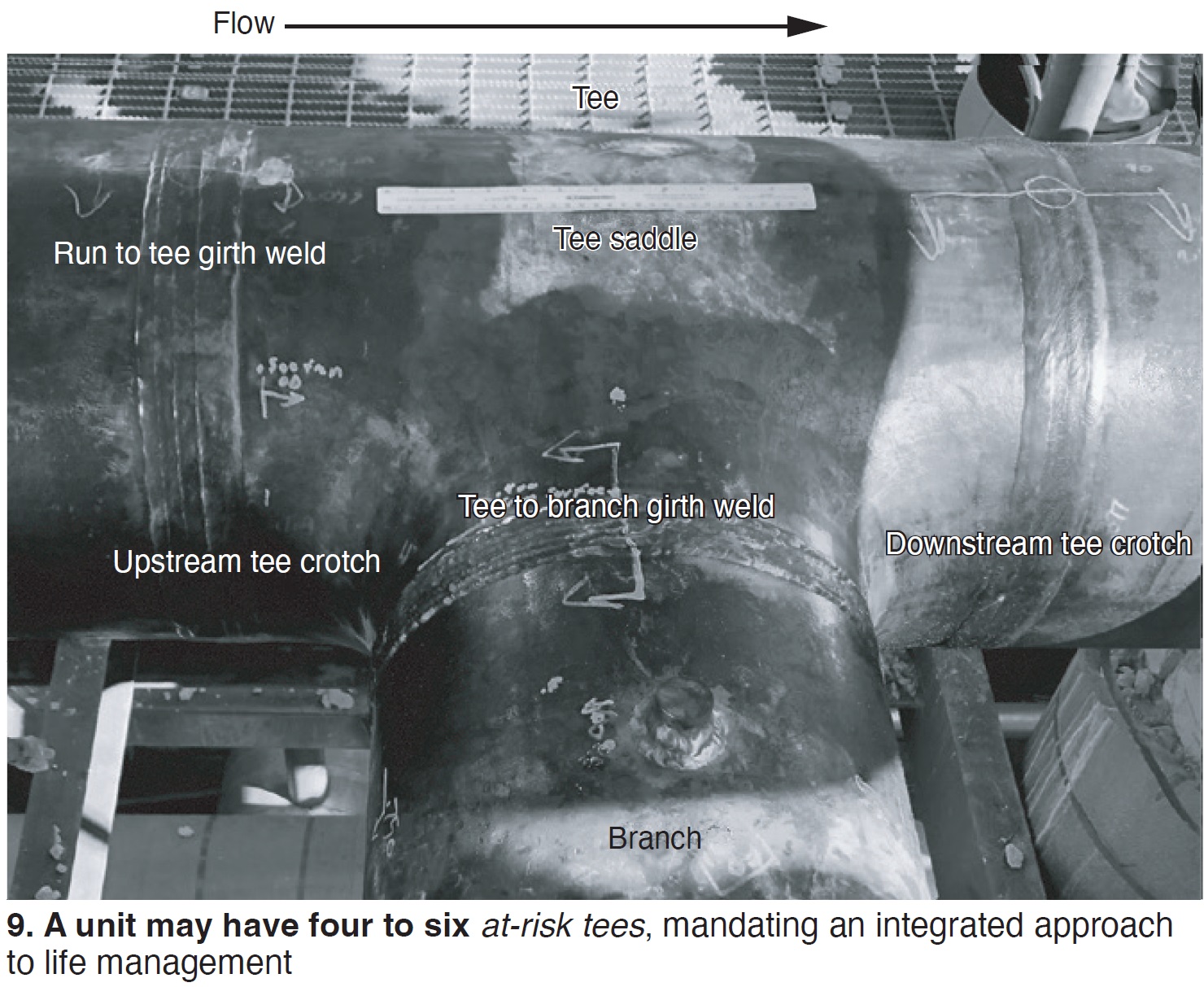

“Steam Leaks in High Temperature Intersections,” Tom Sambor and John Siefert, EPRI

“The race to the bottom has created substantial uncertainty and financial exposure” so say the presenters, with respect to the inadequacies in documentation, fabrication, codes and standards, and materials development for tee piping intersections made of grades 22, 91, or 92 alloys. A single unit may have four to six “at-risk tees” (Fig 9). This “mandates an integrated approach to life management.”