It’s easy to forget about the “big box” selective catalytic reduction (SCR) unit sandwiched in your HRSG modules, even though it stands between you and compliance with your air permit, and your ability to operate.

At the 2017 conference of the Combined Cycle Users Group (CCUG), held in Phoenix the last week of August, Andy Toback, Environex Inc, did his best to remind users that SCR process parameters have to be re-evaluated when gas turbines are upgraded, plant operating tempos change, duct-burner operation is more prevalent or variable, and/or the latest G and H technology machines are being deployed. Otherwise, you may be leaving money on the table or setting yourself up for unexpected costs and performance issues down the road.

Toback’s main message is that you need to adjust the original design expectations for the SCR based on real-world operating data, the key to optimizing the process for new conditions.

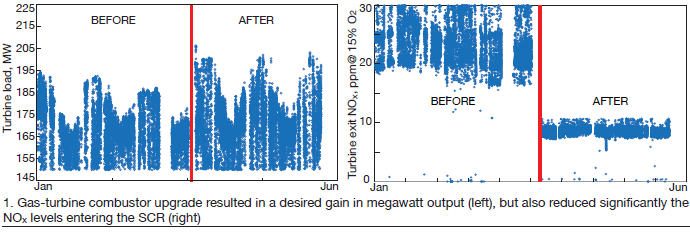

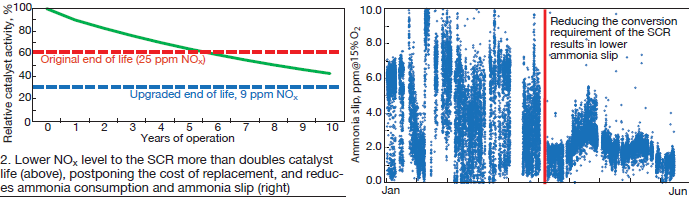

For an actual 7FB.01 to 7FB.04 upgrade, for example, the new combustors added 7 MW of output and lowered turbine NOx levels entering the SCR (Fig 1). Because the catalyst going forward typically will convert 9 ppm NOx levels from the turbine, compared to the original design of 25 ppm, the relative catalyst activity level, representing the expected end of life, can now be projected out beyond 10 years (Fig 2), compared to 5.5 years with the original combustors.

Ammonia consumption and ammonia slip at the stack also are reduced significantly because of the lower NOx conversion requirement for the SCR system. Due to the improved combustor dynamics, gas-turbine CO levels are not expected to change even though the NOx levels have decreased.

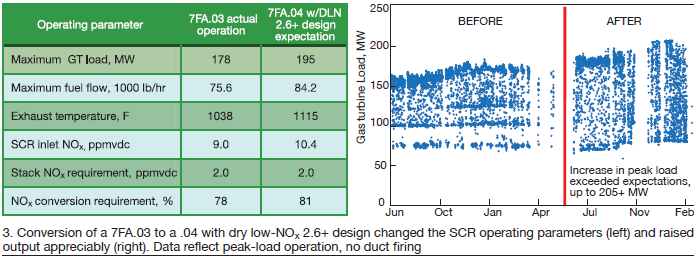

Toback’s second example is a 7FA.03 to 7FA.04 + DLN 2.6+ upgrade (Fig 3). The good news is that the megawatt output gain was higher than expected, another reason why actual measurements are important. However, peak-load fuel and exhaust flows increased accordingly, the turbine exit NOx levels did not change appreciably, but the SCR temperature increased by about 20 deg F after the upgrade.

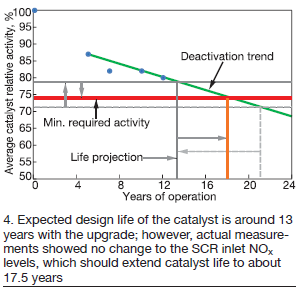

The original Dot 03-machine catalyst design life projection was about 21 years. The upgrade design expectation reduced it to around 13 years. Based on the actual operating data, however, the catalyst life should be more like 18 years (Fig 4). Both an expected increase in engine NOx from 9 to 10.4 ppm and higher exhaust flows impair catalyst life, but because the actual operating data showed no change in gas-turbine NOx levels, the minimum catalyst-activity requirement did not increase as much as anticipated.

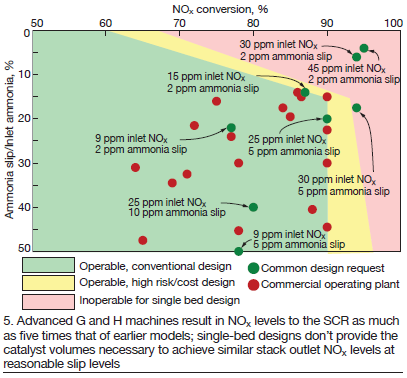

For advanced G and H machines, the news isn’t so good. Toback states, “We’re being asked to achieve the same 2 ppm NOx and ammonia-slip levels (typical of the toughest permits) even though these machines have five times the turbine-exit NOx levels.” Plus, they likely will be required to cycle and operate at less than design output for significant operating hours over their lifetimes.

Fig 5 indicates that for these performance specifications, you’ll either have to accept high operating and compliance risk at the ragged edge of the capabilities of traditional single-bed SCRs or resort to a more complicated and more expensive SCR design.

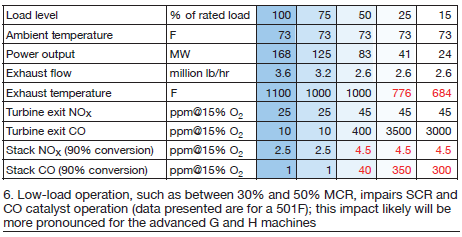

When you operate advanced-technology machines at low loads, you tap out the capabilities of the design (Fig 6). “The ammonia injection grid can’t handle both the NOx levels at the maximum design output and what would be typical at 30-50% load, because of the corresponding changes in mass flow, temperature, and mixing.”

Environex specialists believe owner/operators of G- and H-class machines will have problems because vendors are supplying SCRs with inadequate catalyst volumes. It’s also important to consider adding a permanent grid made of stainless-steel tubing within the HRSG housing which allows you to periodically take 2-D distribution-grid measurements for NOx and NH3 and more accurately tune the AIG distribution valves.

Such capability nominally adds about $50,000 to the budget, a sum that looks paltry compared to the penalties of non-compliance. The high NOx conversion requirements for these systems coupled with low ammonia-slip limits decrease the tolerance for non-ideal ammonia-to-NOx distribution. You should expect this to increase the required frequency for ammonia-grid tuning.

Duct burners, of course, are another source of NOx and CO which must be accounted for through real operating data. SCR inlet NOx can more than double at design GT output and full duct firing and the SCR operating temperature can climb by 50 to 100 deg F. Inlet CO, meanwhile can decrease. During interim periods as duct burners come up to full capacity, or remain at part load, NOx and CO emissions can be quite variable. These impacts can be quite striking if your unit was designed for baseload operation.

Generally, Toback concludes, increases in exhaust flow to the SCR impairs catalyst life, while decreases in SCR inlet NOx and CO emissions and increasing SCR operating temperature extend it. If your machines are no longer operating the way the SCR was designed, it’s time to consider a program to acquire the operating data needed for optimizing the SCR process for new conditions.