The annual conference of the Power Plant Controls Users Group was conducted online for the first time this year. The two-week event, exclusive to owner/operators, began November 10 with a program focused on user experiences and vendor presentations. The latter were limited to 30 minutes each and conducted in two half-hour sessions. Each vendor was assigned a “breakout room” and users were connected to their presentations of choice. While attendees could not participate in more than two vendor presentations during the live Week One program, all presentations—both user and vendor—are available now on the Power Users website, mostly in video format.

Highlights of the Week One user and vendor presentations, developed by the editors, are below.

Week Two (November 17 only) was GE Week, characterized by meaningful technical presentations, Q&A, and open discussion on topics of interest to the user community. Those presentations can be accessed through the OEM’s MyDashboard website. PPCUG2020 concluded end-of-day November 17.

PPCUG2020, Week One user presentations

User presenters wasted no time getting granular in reporting on their plant and portfolio level experiences with GT exhaust thermocouples (t/cs), corporate digital transformation programs, control system and logic mods to support deeper cycling automation, Mark VI control system upgrade, and steam turbine/generator initiated generator purge.

Exhaust thermocouples in 7F machines have been a source of operating issues and instrument failures for years. One combined cycle reported on multi-unit experience with a spring-loaded t/c replacement design. No failures were experienced for the first five years. After that, the plant experienced rapid failures on one unit, then another. You’ll have to access the presentation on the Power Users website to get the details. The plant has not “given up on the design.”

Digital transformation. Big owner/operators often implement big portfolio-wide programs. A representative from one of America’s largest electric utilities reported on progress with its digital transformation program. Truly massive in scale, it includes in-house built sub-programs for digitizing work optimization, work orders, lockout/tagout (LOTO), drone management, machine learning for critical assets, and a reporting, documentation, and comments platform organized to specific plant components and subsystems.

To head off heat-recovery steam generator damage from cycling, one plant reported on modifying the control elements and logic of its originally designed baseload combined-cycle unit to achieve greater automation and avoid the inconsistencies of manual operator intervention. Three focus areas are condensate removal through HRSG drains, attemperator sprays, and damage monitoring. Much of the work in the attemperator area was based on recommendations from an EPRI report.

In upgrading from a Mark V to a Mark VI to solve obsolescence issues, this combined-cycle plant, equipped with four gas turbines, also installed GE’s digital platform. Goals were to use the same control system for all the turbines onsite; make the logic easier to read and consume; minimize HMI changes; share EGD (Ethernet global data) signals; monitor, track, and document relevant test data and results; and automate frequent testing procedures such as lift oil system and emergency bearing oil pumps.

The GT generator remote auto-purge system at this plant never worked properly, and staff wanted to make it operate the way it was supposed to. Fortunately, engineers found a few unused contact outputs in the H2 controls cabinet, upgraded the firmware, added sensors for other purge gases like CO2, and integrated the purge sequence into a graphical interface. Once this was done, operators wanted a similar capability for the steam turbine/generator purge. The remote feature is especially needed in this location because of the frequency of severe weather events—such as hurricanes.

Some of the hair-raising in-field piping configurations, different from design, and discovered only when hardware mods were made, can only be appreciated from the presentation, available to users on the Power Users website. You probably guessed that when operators at other plants learned about the new ST/G remote auto purge system, they wanted one too, so engineers designed one for non-GE units.

PPCUG2020, Week One vendor presentations

Vendor presentations focused on flexibility strategies, small and large control system solutions for gas turbines, integrated control and monitoring solutions for older facilities, legacy controls support, and single-point-of-failure analyses.

Siemens Energy’s Galen George addressed a round-robin of options for achieving flexibility when a combined-cycle plant’s load curve shifts because of renewable energy coming online in the market or service territory. Siemens’ Jim Badgerow supplemented the discussion by illustrating how battery energy storage systems can work with traditional GT plants.

PSM reviewed how the company’s Autotune rack-mounted controls solution, now 10 years mature in version 3, can satisfy small goals, like saving minutes on a simple-cycle unit startup, and large ones, like customizing a unit for greater fuel flexibility, capacity augmentation, and better turndown. Autotune is a machine-learning solution—it captures data from successful and unsuccessful starts/load change events. Need for tuning decreases as learning progresses.

MD&A’s Michael Broggi, along with Craig Corzine, CSE Engineering Inc (MD&A purchased the rights to CSE’s IBECs HMI platform), touted IBECs ability to integrate disparate control systems in older plants—such as turbine excitation, continuous emissions monitoring (CEMS), vibration monitoring, gas condition monitoring, generator relays, auxiliary PLCs, and balance of plant. Critical areas for success focused on by the presenters are time synchronization, sequence of events, high-speed data transmission versus historian-type data rates, data export, encryption, alarms, and reports.

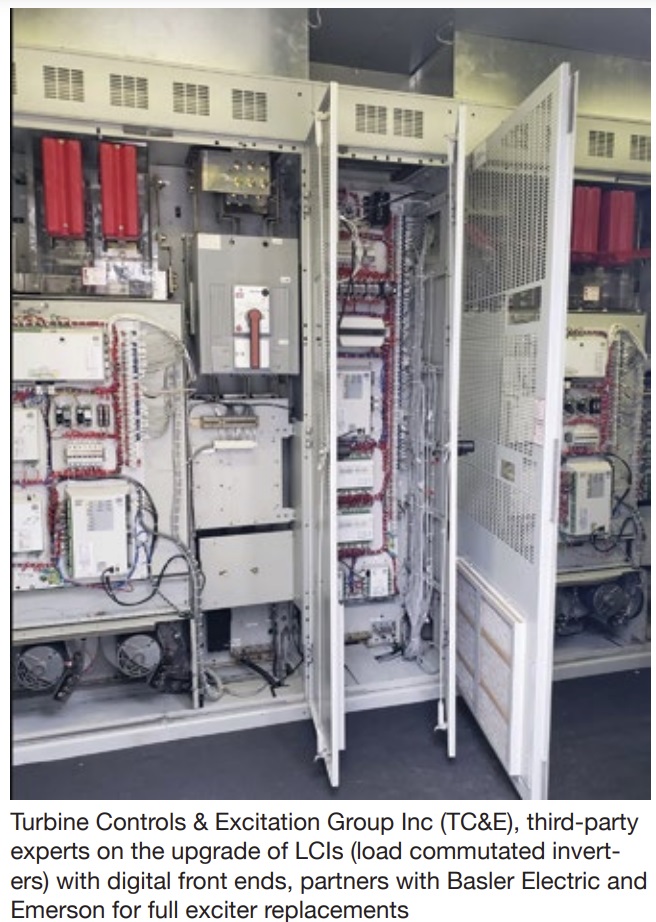

TC&E’s John Downing presented his firm’s capabilities with digital front ends (DFE) for exciter controls. The company boasts over 200 Innovation Series load commutated inverters (LCIs) with DFEs. TC&E has partnered with Basler Electric and Emerson for full exciter replacements. Some of the additional reliability scope can include water-cooled busbar and resistor components testing and replacement; check valves, 3-way pump valves, and other pump panel components, and Nato board replacement.

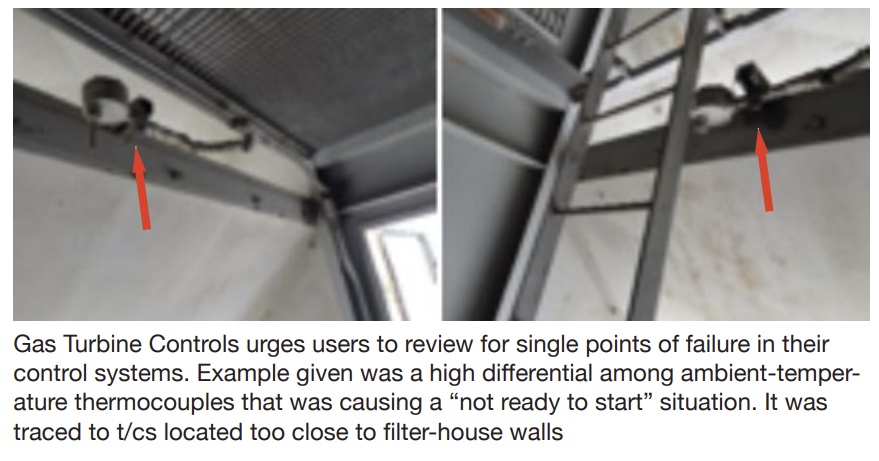

Gas Turbine Controls. Capping Week 1, Chief Engineer Abel Rochwarger addressed solutions for GE TIL-1524 (when one exhaust TC fails high) and GE TIL-1275 (high P2 pressure control), as well as for speed-pickup spikes, date cards from 1990-2001, and other cards in the Mark V and VI control systems.

Cemtek KVB-Enertec’s Gary Caccciatore discussed the benefits of using the company’s cross stack TDL/DOAS technology to measure O2, CO, CH4, NOx, and NH3 on gas-turbine inlet monitoring in pace of the typical extractive CEMS technology. Advantages include immediate response time, accuracy, and reduced CEMS maintenance and spare parts.