By Vaughn Watson, Vector Systems Inc

The efficiency and long-term performance of an SCR depends largely on several key design considerations regarding various system components. When complex NOₓ reductions on combined cycles are required, there are critical values related to the fluid distribution in the system which must be addressed to ensure success.

While the SCR catalyst often gets all the credit, and all the blame when performance declines, careful study of catalyst design, and of the entire system, can alleviate or prevent many of the top factors that contribute to SCR issues.

SCR system performance is largely dictated by ensuring adequate distribution of the exhaust gas to meet the catalyst volumetric sizing. The distribution metrics typically are the following:

- Velocity (at the catalyst face), ±15% RMS.

- Temperature, ±25 deg F.

- NH₃/NOₓ, ±10% RMS.

SCR catalyst design itself is crucial to the effectiveness of the emissions control system. Catalyst volume, formulation, and pressure drop, must consider the totality of operating scenarios the combined cycle unit will encounter. This evaluation should include each load level the combined cycle unit will operate within and consider all ambient conditions expected as well the fuels burned. Consideration of multiple fuels and blended fuel streams is especially important.

Your evaluation must include all operating cases from the combined-cycle OEM, plus interpolation of existing plant DCS data trends. Don’t overlook unit turndown: It too must be evaluated because the NOₓ produced typically is higher at lower loads, and the decrease in exhaust temperature will limit SCR catalyst efficiency.

Stratification and speciation of the NOₓ also are important. Ideally, the NO/NO₂ ratio should be 50% or less NO. Additional testing to ascertain the NO/NO₂ speciation may be necessary because a high NO₂ speciation can be a major issue for SCR efficiency and require specific catalyst formulations to achieve NOₓ reductions.

Catalyst bypass can greatly affect NOₓ reduction and ammonia slip. Bypass must be limited to less than 1%. The catalyst support structure and perimeter seals should be inspected during outages for any areas that may have exhaust-gas and ammonia bypass. Catalyst modules must be well packed to ensure no ammoniated exhaust gas is flowing unreacted through gaps around the catalyst bed. On a high-performance SCR, small amounts of bypass can drastically add up to the inability to meet emissions limits.

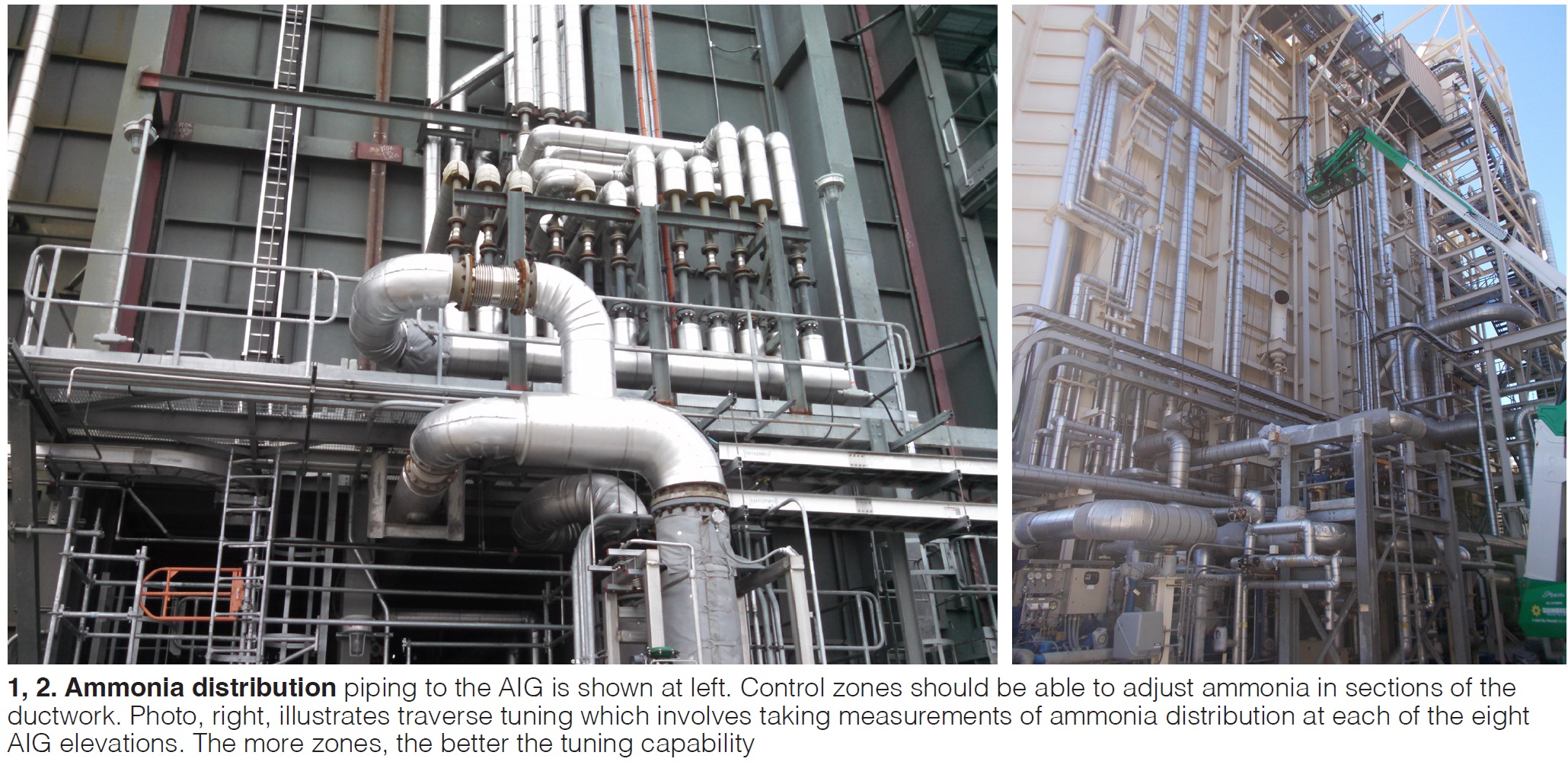

Ammonia distribution within the exhaust gas cross-section is a huge factor in the catalyst’s ability to properly reduce NOₓ levels (Figs 1 and 2). This important part of the system largely falls to the design of the ammonia injection grid (AIG). It must consider both the amount of ammonia and diluent required to inject and mix with the NOₓ present in the exhaust gas.

Careful consideration of injection pressures, mass flow, and density change along the length of each AIG lance are essential for proper distribution and mixing. AIG design for advanced NOₓ control must consider orifice size, spacing, and angle of injection necessary to ensure the proper distribution. This is critical to ensuring the NH₃:NOₓ distribution is matched to the volume of SCR catalyst.

SCR catalyst and the AIG should be inspected during every outage to ensure there is no significant plugging, which can have a major effect on SCR performance by impacting ammonia distribution. Recall that catalyst fouling masks the active pore sites on the catalyst substrate. If you find plugging, eliminate it immediately and determine the root cause. Finally, remember that AIG design can be improved for better distribution and performance, and help provide significant resilience against frequent plugging issues.

Ammonia purity. Specifying the correct purity grade of ammonia is critical. For aqueous systems, reagent-grade ammonia is the best option. The key differentiation lies with the purity of the water in the solution. Avoid water with soluble minerals that can plug, foul, erode, and damage SCR equipment. Such impurities can lead to vaporizer fouling, AIG plugging, and potential catalyst performance problems. It only takes one bad load of reagent to experience the headaches associated with ammonia impurity.

Backpressure effects on distribution. Velocity profiles are critical for SCR catalyst performance, and all catalyst guarantees have a velocity-profile requirement associated with the SCR design. Ductwork often does not have sufficient pressure drop through the components in the gas path to “flatten” this profile. The result is high velocities in the center and excessive stack emissions. In today’s world of emission requirements (2 ppm NOₓ and 2 ppm ammonia slip) the effects of not having sufficient backpressure become very evident.

In some of the advanced SCR catalyst designs being implemented, there is insufficient backpressure to promote the degree of mixing required. In many cases, an existing AIG cannot adequately distribute and mix the ammonia and NOₓ with the reduced backpressure of a modern catalyst.

SCR and CO catalysts typically operate at 25% to 40% below their manufacturer-guaranteed pressure-drop numbers, at least early in their lives. In recent years, suppliers have developed an ultra-low-pressure-drop module design. These are good for retrofits into existing sites, but recent experience suggests new installations may suffer if these components are not applied properly. Even designs based on CFD models of gas-side flow can miss the mark by as much as 30% to 40% based on field measurements.

Recently, the author had the opportunity to examine two units at a site that had just replaced its SCR catalyst. Unit 2 was failing emission guarantees right after changing its catalyst. By contrast, Unit 1 was running better on a 13-year-old catalyst than Unit 2 with the new catalyst.

Site personnel blamed the catalyst vendor. However, it was clear after evaluating the operating data, that while the site was saving almost 2.2 in. H₂O of backpressure on the gas turbine, the new catalyst had changed the flow distribution through the SCR. The AIG was marginal back in the day, but the backpressure of the old catalyst was flattening the flow and allowing for adequate mixing. Redesign of the AIG and a relatively simple retrofit has the site back up and running with a highly efficient SCR system. Both pressure drop and ammonia consumption have been reduced.

End note: By ensuring the design factors discussed above are considered in your SCR and ammonia systems, and addressing problems when they are discovered, you’ll have an efficient SCR system capable of advanced NOₓ reduction.