By Steven C Stultz, Consulting Editor

The third conference on Materials, Inspection, Monitoring, and Assessment (MIMA-3), conducted by UK-based European Technology Development Ltd (ETD) last October (2023), in London, focused on sustainable power generation. Discussions and presentations addressed challenges associated with fossil and nuclear power generation, low- or no-carbon fuels, and renewables technologies.

Highlights of the two earlier meetings—held in October 2020 and October 2022—were published in CCJ.

The 2023 event was coordinated by EDT Consulting’s Ahmed Shibli and chaired by Staf Huysman of Belgium-based Engie Laborelec, an organization similar in many respects to US-based EPRI. Note that ETD Consulting is a trading name of European Technology Development Ltd, Leatherhead, Surrey, UK.

As stated by Shibli, managing director of ETD, “The aim of this international conference is the exchange of knowledge and experience related to various plant issues including decarbonization, materials, inspection/monitoring, safe operation and condition/life assessment.”

MIMA conferences are attended by plant operators, owners, designers, fabricators, insurance companies, and service providers along with research institutes and universities from various countries.

Below are selected highlights from MIMA-3. Not all content is reported. The agenda and further details are available through enquiries@etd-consulting.com.

Hydrogen

Sessions began with the keynote presentation, Long-term impact of hydrogen combustion on gas-turbine hardware, by Kurt Boschmans, Engie Laborelec. The subtitle of this increasingly relevant topic was Building decarbonization pathways for Europe: Engie’s scenario.

Boschmans began with the basic concept: “By replacing methane with hydrogen, gas turbines can potentially be converted into low-carbon-, or even zero-carbon-, emitting assets. The CO2, formed during combustion of methane, is replaced by H2O.”

There is, of course, much more to the story, as he explained.

Some fundamentals from Engie’s perspective:

- Co-combustion of 30 vol% H2 can reduce carbon emissions by 10%.

- 80 vol% H2 can cut carbon emissions in half.

Boschmans then outlined Engie’s perspective on what he called “a few values,” which he supported with these examples:

- Higher adiabatic flame temperature of hydrogen will lead to higher NOx emissions, when combustion occurs in stoichiometric conditions (1:1).

- In gas turbines, the combustion system is typically based on dry-low-NOx (DLN) burner technology, in which acceptable NOx levels are achieved by combustion of a lean, premixed fuel/air mixture.

- The lower flammability limit for hydrogen suggests that even leaner fuel mixtures could still be flammable, in contrast with methane.

- The much wider flammability limits also clearly illustrate the importance of safety when dealing with hydrogen.

- For an existing burner design, the higher flame speed associated with hydrogen will make a flame burn closer to the burner (as it becomes richer in hydrogen).

- Difference in volumetric energy density suggests that the required volumetric flow of hydrogen to get the same power output as methane is nearly 2.5 times higher.

One example: Co-combustion of hydrogen up to 30 vol% was tested in Belgium operating an SGT-600 gas turbine. Looking closely at flame positioning, flame anchoring, and flashback, this suggests the need for burner design changes, with potential adaptation of DLN technology. He suggests a move toward modifications in size, shape, and/or number of injection ports, among other items.

Boschmans then looked closely at the influence of hydrogen on gas-turbine hardware, suggesting that “increased amounts of water vapor in the flue gas have a negative influence on the stability of the protective oxide scale formed on superalloy materials.”

Engie in Belgium is working with Cranfield University in the UK on various materials and environments.

He then turned to a few pilot projects operating in Europe, working with Siemens, John Cockerill, and others including—Ansaldo and GE.

His conclusions:

- Based on available information, hydrogen combustion in gas turbines is feasible. Co-combustion of hydrogen up to 30 vol% can be achieved without any noticeable negative influence on gas-turbine hardware.

- First demonstrator plants with industrial gas turbines are currently running to test production on pure hydrogen.

- Hardware to allow combustion of pure hydrogen in large F- or H-class heavy-duty gas turbines has not yet been fully developed. However, there is a clear commitment of the OEM suppliers to be ready by 2030.

This was followed by Materials for H2-fired industrial gas turbines by Cranfield University, then by Technology adoption in fossil-fuel powerplants in the decarbonization era by TNB Power Generation, Malaysia. Fred Star, ETD consultant, also discussed Hydrogen: the backup for wind power.

Hong Wei Wang, ETD, wrapped up the session with Opportunities and technical challenges of H2 in combined-cycle gas turbines, an in-depth technical look at hydrogen production, storage, and transmission; hydrogen effect on materials—including pipelines, storage tanks, and CCGT systems; and a review of the opportunities and challenges.

Selected concluding remarks:

- Great potential but not there yet.

- Handling infrastructure needs to be developed (at scale).

- Increased capacity of water electrolyzers above 100 MW needed.

- Repurposing required for existing pipelines and gas turbines.

- Need research on new materials.

- Need new engineering codes and code-case materials as basis.

HRSGs

Keynote for Session 2 was Hydropower and integration of renewable energy by Maryse Francois, NFX Consulting, France. The presentation discussed how hydro power, including pumped storage, can contribute to grid stability. She used examples from China, Israel, Australia, Switzerland, and Portugal.

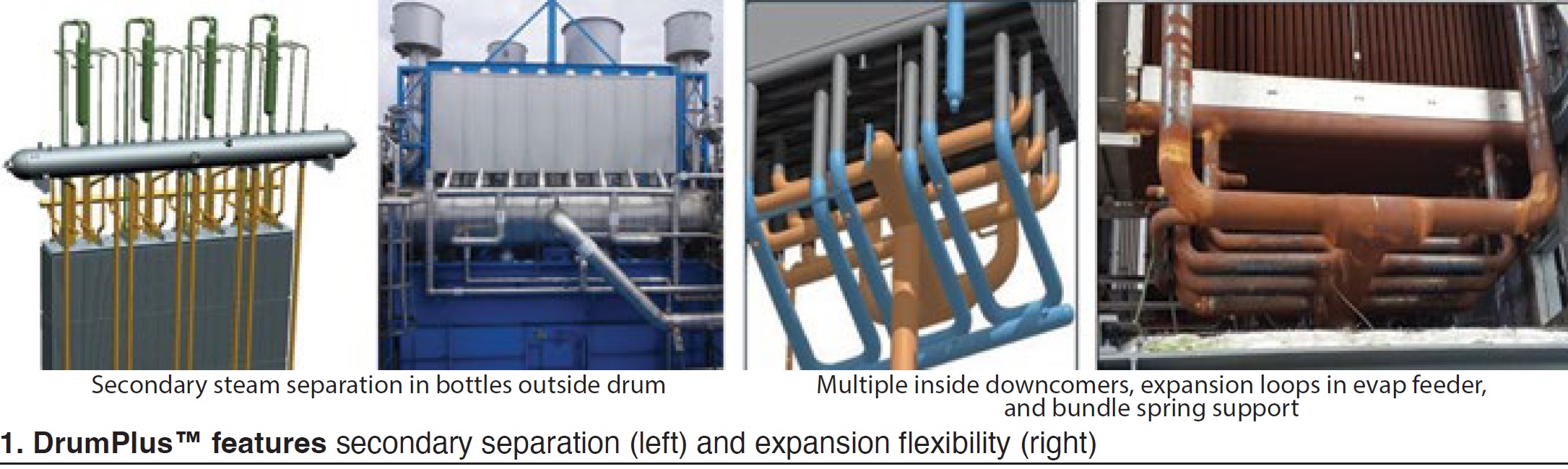

The second keynote was Flexible and future-proof HRSGs by Sebastiaan Ruijgrok, NEM Energy, The Netherlands, featuring NEM’s DrumPlus™ fast-start and cycling design work.

He first looked at lifetime impact of low-cycle fatigue and the impact of component expansion differences where dissimilar metal components are joined. DrumPlus features secondary steam separation in bottles outside the drum. Multiple inside downcomers, expansion loops in evaporator feed, and spring bundle supports enhance expansion flexibility (Fig 1).

Some lifetime improvement predictions were included for numbers of cold, warm, and hot starts. Two case histories were reviewed: El Segundo in California, and Lordstown Energy Center in Ohio. He ended with a look at HRSG readiness factors for hydrogen combustion.

ETD’s Shibli followed with a detailed review of ETD’s studies of fossil powerplant flexible operation in Europe, North America, and Asia: Technical and cost issues. This presentation, available through enquiries@etd-consulting.com, discusses the technical and financial benchmarking of conventional and combined-cycle plants operating in the cycling regime through statistical analysis, and assesses the relative impact of startups on a range of plant sizes, configurations, and age.

Nadeem Ahmed, ETD, followed with development of a reliability management framework and practical implementation ideas, including maintenance program adjustments and performance monitoring techniques.

Session 2 included Ahmed’s Powerplant cost impacts, cycling, and reliability issues, discussing “an embedded approach including integration of risk-based inspection and reliability-centered maintenance within an asset performance-management system.”

Wind

Session 3 focused in part on wind-turbine inspection and damage analysis. Sarinova Simandjuntak of Anglia Ruskin University, UK, opened with an overview on wind-turbine blade, column, and base inspections—including new sensor development.

Ilosta Ltd (UK) offered Enhancing the reliability of wind-turbine-blade inspection procedures using AI. This was supported by other turbine-blade evaluation discussions and the use of hyperspectral imagery for damage assessment by the University of Portsmouth and St. John’s Innovation Center, both UK.

Tee intersection and other failures

Session 3 then focused on materials development for creep modeling, material failures, and P91 inspection in fossil and Gen IV nuclear plants.

CCJ recently reviewed a January 2024 webinar featuring Jeff Henry, ATC, on premature failure of formed tees in high-energy piping. Also, EPRI has cautioned us about premature failures of these tee intersections, primarily because of creep damage. This topic was included in MIMA-3.

ETD’s David Robertson led a discussion on the consultancy’s Group Sponsored Project for early-stage creep cavitation detection in P91 tee pieces.

The premise: “Thick-section components generally have failed by Type IV cracking at the heat-affected zone (HAZ) of the welded components. The damage/cracking tends to start sub-surface and can only be detected by traditional NDE techniques at about 70% to 80% of consumed life, which means the damage cannot always be detected in time by standard inspection techniques (such as replication). This makes the structures potentially liable to failure before the next inspection.”

This is consistent with Henry’s webinar, and the topic continued in Session 4 (see below).

Specific Session 3 papers also included:

- Creep lifetime prediction method using the cavitated volume fraction approach, University of Huddersfield, UK.

- TP304H reheater-tube failure attributed to sigma-phase embrittlement, TNB Research, Malaysia.

Materials

The keynote for Session 4 was Enhancing integrity of P91 steel pipe in a supercritical thermal and Generation IV nuclear power plant by the Korean Atomic Energy Research Institute, followed by Transfusion: A project to transfer high-temperature materials technology from fossil to fusion energy by ETD’s David Allen and others, including the UK Atomic Energy Authority.

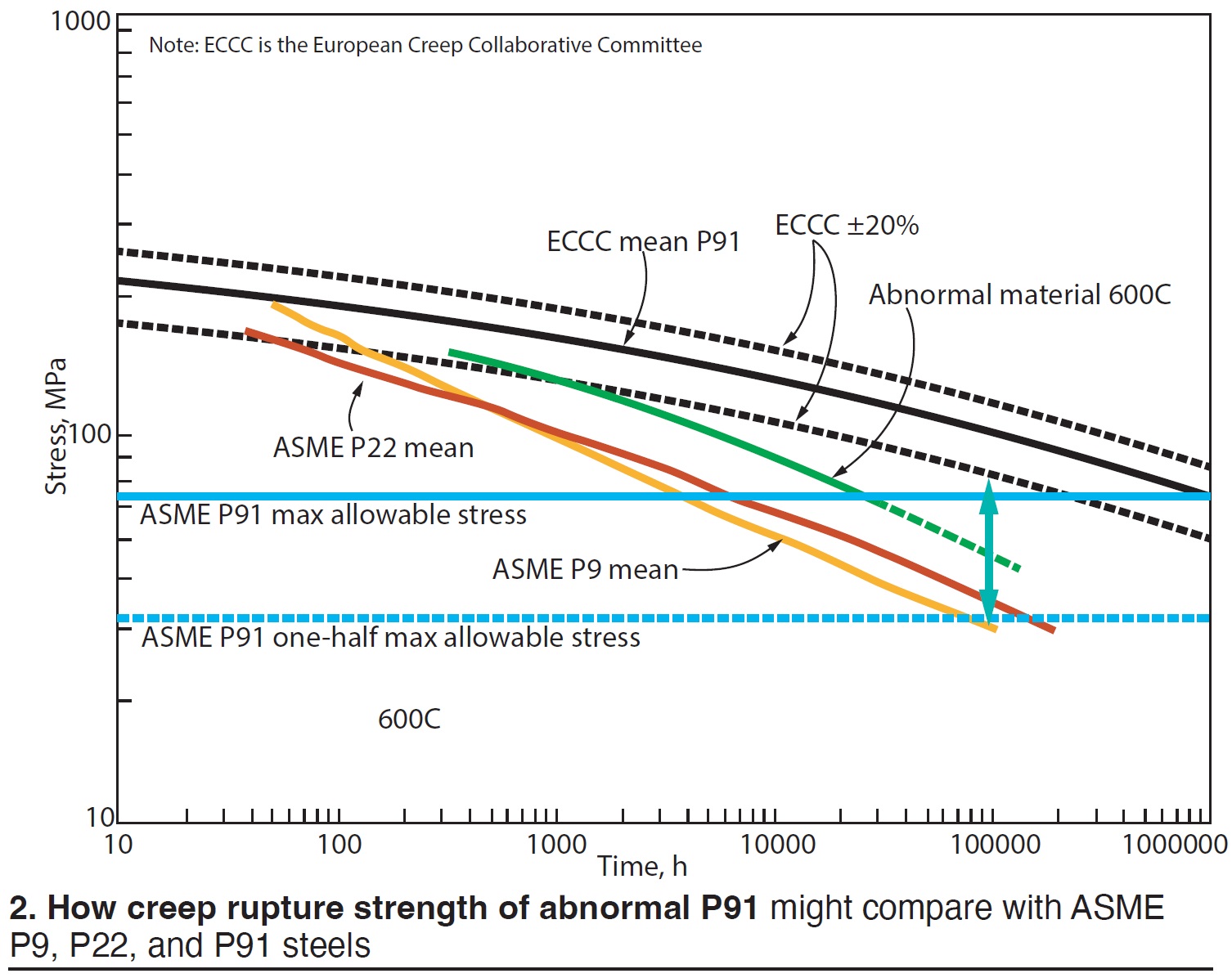

Robertson, along with Engie Laborelec, Belgium, and the Central Research Institute of Electric Power Industry (CRIEPI), Japan, then presented Long-term creep testing of aberrant P91 materials for component life prediction.

This offered an investigation of different abnormal heat treatments, welding procedures, and repeat weld repairs commonly experienced globally.

Robertson’s starting points:

- Many utilities worldwide have been discovering abnormal (aberrant) P91 base metal and welded joints in their plants.

-

- Heat treatment is critical to achieving full strength in high-Cr martensitic steels, but many material suppliers, manufacturers, and welding companies have failed to realize this criticality.

- Hardness below the acceptable limit and/or the microstructure was not in the correct, fully martensitic condition.

- Deviations from optimal chemical composition can also result in abnormal microstructural conditions.

-

- Many abnormal P91 components/welds have only been found some years after entering service.

-

- Not all abnormal components/welds can be replaced immediately; some may have to remain in service.

- Plant owners/operators do not know how to manage these components in the absence of long-term creep strength data for aberrant materials (Fig 2).

-

This project offers a comprehensive review of test programs with creep rupture test data of up to 40,000 hours and beyond, produced from project sponsors in Europe and Japan. Additional sponsorship opportunities can be discussed through enquiries@etd-consulting.com.

The University of Science & Technology, Beijing, discussed life evaluation of 9Cr steels in ultra-supercritical powerplants followed by the KTH Royal Institute of Technology (Sweden) looking at creep at very low stresses.

Huddersfield University offered a cavitation-based method for creep lifetime prediction using Cu-Zn-2PB material followed by a modeling method from its School of Computing and Engineering.

CLP (Hong Kong) presented Dosing-layer quality monitoring in condenser tubes. Next was Challenges and parameters effect of wire-arc additive manufacturing (WAAM) of nickel-based alloys by the Belgian Welding Institute and Engie Laborelec. Altrad Babcock (previously Doosan UK) followed with a discussion of cracking in 15NiCuMoNb5 marine- and power-boiler drums.

TNB Research, Malaysia, followed with TP304H finishing reheater tube failure due to sigma phase embrittlement and the University of Huddersfield ended the session with Creep damage and creep lifetime prediction: Correlation or causation?

Inspection, monitoring

The keynote for Session 5 was DX (digital transformation) of plant maintenance with online monitoring and AI, by Japan’s Best Materia Co.

Portable scanning force microscopy (SFM) for early-stage creep and fatigue damage then was presented by Andrea Tonti of Italy’s INAIL and ETD’s Cheng-Jung Lin.

SFM can detect creep cavities from a few nanometers to microns in size, allowing detection and monitoring of early-stage creep in martensitic steels using this portable device (Fig 3).

ETD has used SFM onsite in Italy, France, Poland, Malaysia, and Philippines for early-stage creep detection in P91 martensitic and low-alloy steel components. One recently tested application is onsite NDE and life assessment of gas-turbine blades, significantly reducing owner/operator inspection costs.

A few conclusions:

- Creep damage in P91 components can be detected at a very early stage (about 20% to 30% of life), quantified, and used for life assessment.

- Damage detection is of much higher quality than replication.

- Portable SFM can also be used for in-situ nondestructive microstructural damage deterioration and life assessment of gas turbine blades.

Kobe Material Testing Laboratory (KMTL) and CRIEPI, both Japan, followed with a discussion of ultra-miniature specimens for life assessment in older powerplants, followed by EDF Energy (France) looking at more effective use of plant inspection and monitoring data.

Further developments in ETD’s CrackFit software for the assessment of cracks in boilers and turbineswas discussed by Stuart Holdsworth of Switzerland’s EMPA, working as ETD’s consultant and with other ETD experts. Defect-assessment procedures and software are applied to defect assessment of components and welds. CrackFit is now being enhanced for turbine rotor steels, gas-turbine blades, and disc forgings.

CrackFit includes extensive creep and fatigue crack initiation and growth data for most commonly used plant materials, including base and weld metals and HAZ.

Scanning electrical pressure drop (S-EPD) for online and offline NDT determination of remaining life in P91 pressure vessels and welds was shown by Adam Wojcik, Matelect, and University College London (offline component testing), working with ETD.

Magscan-2 is a rapid scanning electromagnetic tool for quality assurance of P91 and P92 plant components and scanning for aberrant microstructure. Its background, fundamentals, and use were described by the University of Manchester and ETD. Some of the samples presented were supplied by EPRI.

Daniel Omacht, Vitkovic (Czech Republic), discussed a portable instrumented indentation machine and software for more accurate interpretation of test results for fracture toughness and other properties. This work is conducted jointly by Vitkovic, Kema (Netherlands), and EPRI (Shenyang, China).

Ilosta Ltd ended the session with an Advanced data-analysis procedure for improving failure assessment of cracks in pipes, also covering pressure vessels and crack growth over time.

Sponsors for MIMA-3 included Altrad, Matelect, AGTec (Austria), and Spectrographic (UK).

Future conferences

Discussions on the last day of MIMA-3 considered several topic possibilities for future consideration by the conference organizers—including renewables, nuclear power, drones, robots, hydrogen updates, ammonia plants, decarbonization—with added emphasis on the economics and political drivers of new developments. Thoughts? Please share by writing to enquiries@etd-consulting.com.