Faribault Energy Park

Owned by Minnesota Municipal Power Agency

Operated by NAES Corp

265 MW, 1 × 1 7F-powered combined cycle equipped with a GE A10 steam turbine, located in Faribault, Minn

Plant manager: Shawn Flake

Challenge. Combined-cycle powerplants have changed their operating profiles to accommodate grid demands for flexible generation. Example: MISO territory has a significant amount of wind energy in its portfolio, requiring Faribault to cycle daily because of excess wind generation overnight.

Faribault Energy Park primarily covers intermediate- and peak-load requirements. Today’s energy market has required the plant to provide faster starts and reduce startup costs while maintaining equipment health and reliability over its lifetime.

The cyclic profile of the steam turbine has increased rotor low-cycle fatigue which must be properly managed to reduce the unit’s life consumption per start. Objective is to operate well beyond the typical 30-yr lifespan that plants typically are designed for. Historically, turbine OEMs have provided startup guidelines and ramping practices that were conservative but didn’t manage stress properly.

Solution. Faribault implemented steam-turbine Agility starts for its A10 machine with the primary goal of providing faster combined-cycle starts while consuming rotor life at a rate commensurate with, or less than, baseline consumption. The ST controller calculates the optimal steam temperature to minimize startup times based on the rotor’s warming profile. Rotor cyclic stress is minimized at the same time.

The calculated steam-temperature value is input to the gas-turbine control system and steam-attemperator logic. The GT acts as the primary steam-temperature controller by varying turbine exhaust temperature to the HRSG. Attemperators act as a secondary steam-temperature controller, minimizing—often eliminating—the need to use spray water during startup.

Results. Succinctly, implementing ST Agility starts has decreased fast-start time while reducing rotor stresses that consume life.

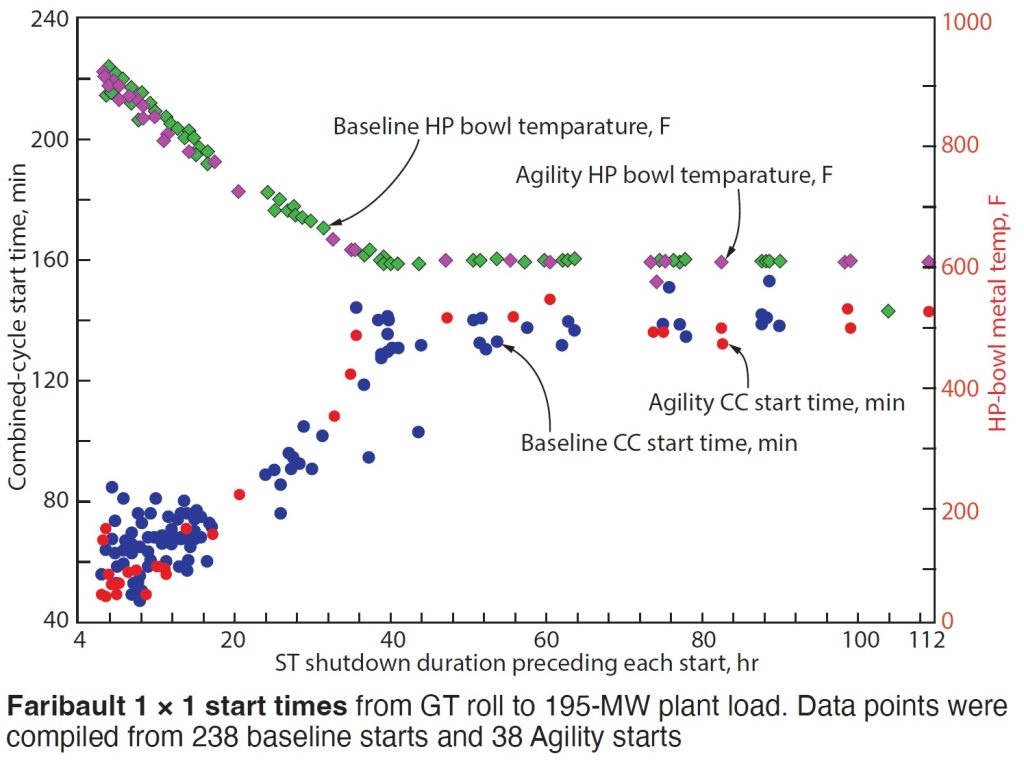

More specifically, combined-cycle start times, after a shutdown duration of 16 hours or less, have been reduced by nearly 10 minutes consistently (figure). Typically, with daily cycling, the shutdown duration is eight hours. Faster starts make the plant more responsive to grid needs while saving fuel. Shorter startup times are achieved by releasing the gas turbine at the optimal time to ramp to market based on steam-turbine rotor stresses.

Rotor stresses have been controlled by creating a stress “budget” for each startup. Stress targets, measured in kilopounds per square inch (ksi), are used to reach minimum and maximum stress limits, allowing each start to consume a budgeted amount of life.

Prior to the upgrade, rotor stress trends on warm starts had several peaks and valleys throughout the warmup phase. Controlling the steam temperature to hit plant’s ksi targets has removed the peak and valley effect of a traditional warming cycle. Rotor stresses now reach the peak target, hold peak stresses through warmup, and release on the back end creating a plateau effect.

Project participants:

Shawn Flake, plant manager

Scott Lowe, operations manager

Tim Mallinger, lead operator