By Steven C Stultz, Consulting Editor

The sixth annual IAPWS Conference on Film Forming Substances, held March 21-23 (2023) in Prato, Italy, was chaired by Barry Dooley of Structural Integrity Associates (UK) and David Addison of Thermal Chemistry (New Zealand). FFS conferences, sponsored by the International Association for the Properties of Water and Steam, are unique, as evidenced by the focus here on this narrow topic in cycle-chemistry control of powerplants and steam generating facilities.

Film forming substances consist of two main categories of chemicals using the internationally accepted nomenclature: amine-based (FFA, Film Forming Amine, and FFAP, Film Forming Amine Product) and non-amine-based (FFP, Film Forming Products) which are proprietary compositions.

There had been general confusion on the nomenclature, but these terms introduced by IAPWS in 2016 have quickly become the global standard. For background, see CCJ’s report on the Fifth International Conference and “Protection of metal surfaces: A wakeup call on film-forming substances.”

In 2023 the conference attracted 70 participants from 28 countries which included 20 plant operators/users and representatives from 11 FFS chemical suppliers.

As stated by Dooley, “The major activities at FFS 2023 were multiple presentations and discussion sessions outlining the current knowns and unknowns about FFS and their properties in relation to their application as corrosion inhibitors in fossil, industrial, nuclear, and other water/steam plants. Key research needs were documented by the conference attendees, which included the majority of global FFS suppliers, multiple users, research groups, and independent industry experts.”

Below are notes and background for owners/operators of combined-cycle and other powerplants, in particular those facing the increasing need to protect their equipment and systems during recurring on/off cycles and layup.

The launch

Dooley and Addison launched the conference with an overview and some significant timely points. Interest remains paramount on the following potential benefits of FFS:

- Shutdown protection under wet and dry conditions.

- Avoiding boiler and HRSG tube failures from under-deposit corrosion and corrosion fatigue.

- Arresting both single- and two-phase flow accelerated corrosion (FAC).

They also launched the proceedings with a clear picture of future fundamental work requirements, including but not limited to:

- Recognition that much current work is on metal surfaces rather than on the oxide surfaces.

- Effect of FFS on growth mechanisms of Fe, Cu, and Cr oxides in water and steam.

- Uncertainty of stability limit and decomposition products for all FFA and especially FFP.

- Information on changing from one FFS to another.

Again, this is only a partial list. The opening presentation gave relevant details of each.

Dooley ended the launch with two Cardinal Rules:

Rule 1. Make sure plant chemistry is optimized before application of an FFS.

Rule 2. Conduct a complete review (due diligence) before an FFS application.

Note that comprehensive guidance on the use of FFS is openly available through IAPWS. Go to http://www.iapws.org/techguide/FFS-Industrial.html. Section 8 of TGD8-16(2019), pp 19-32, provides operational guidance for operators/users on the continuous addition of an FFS.

An HRSG in Spain

Andre de Bache, Kurita, gave a brief history of Cetamine® leading to Cetamine G85X, a single-component FFA based on OLDA (Oleyl propylenediamine). He followed with a specific example of Cetamine treatment for a 400-MW HRSG in Spain facing continuous startups and shutdowns. The original baseload water-treatment plan was giving very poor corrosion protection.

The NEM HRSG was commissioned in 2005. As a direct result of cycling, inspection results between 2017 and 2020 revealed generalized FAC on various internal surfaces, and gradual wall thickness decrease from inside LP evaporator tubes.

FFS dosing began in 2021. Resulting cation conductivity reports, particle counts, and blowdown water consumption were reviewed in detail.

Bache’s conclusions: Cetamine G85X is offering beneficial protection during both cycling operation and preservation periods. It can be used as an additional treatment to conventional AVT or AVT+PT. It has reduced startup times and need for blowdown.

Steam condenser efficiency

Later in the day, Mahesh Budhathoki, Veolia, discussed steam-condenser efficiency improvements in a combined cycle using FFAs. This presentation began with descriptions of Polyamine Plus’ (PAP) potential advantages to power producers—including the following:

- Offers a beneficial layup method when not using nitrogen.

- Allows faster startups.

- Reduces chemical cleaning expense.

- Provides general corrosion and FAC protection during operation.

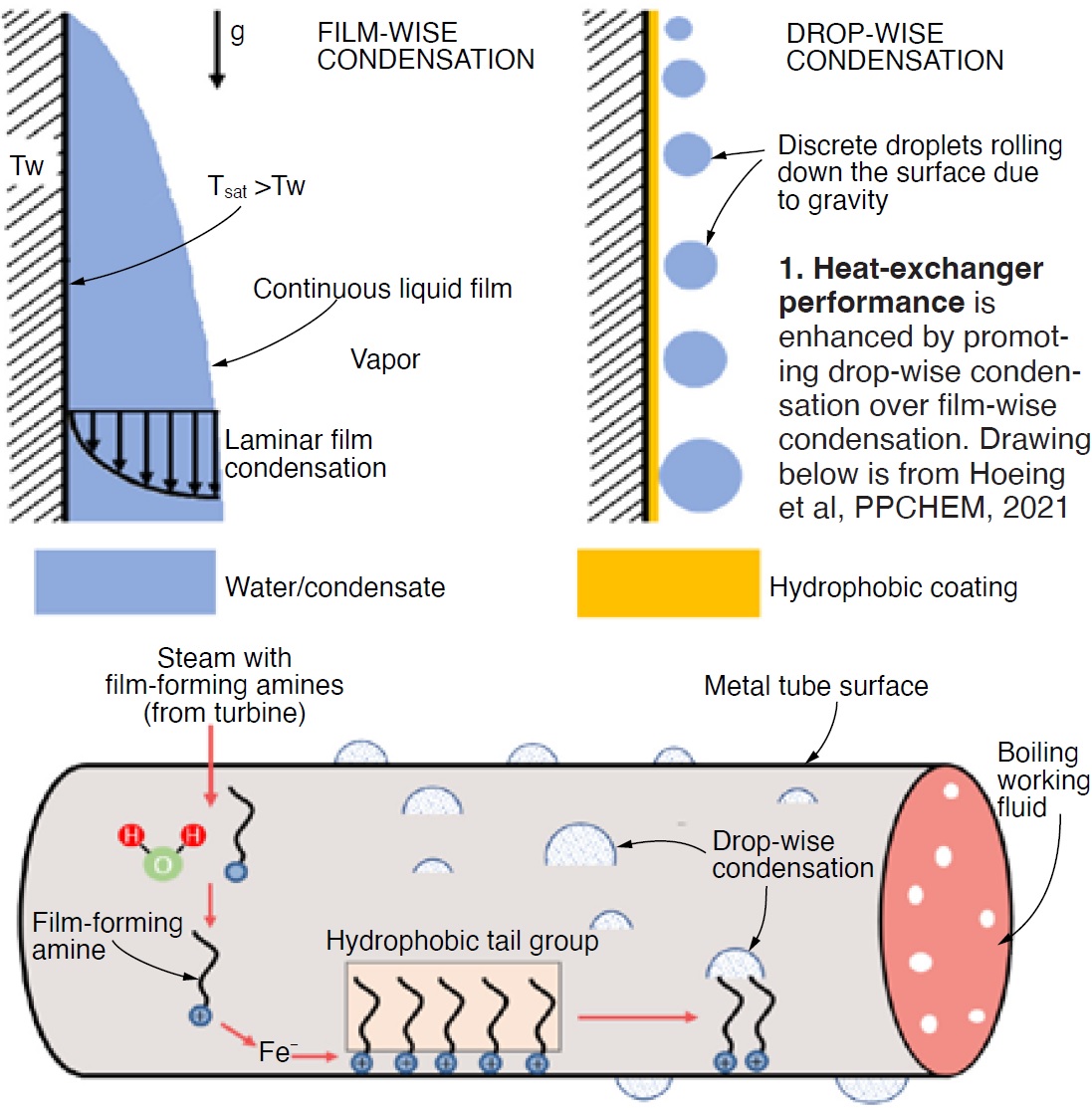

Case study premise: The method tested allows complete system protection from a single feed point and improves condenser performance and efficiency. A driving factor seemed to be an increase in dropwise condensation (Fig 1).

The case history focused on shell-and-tube condenser cleanliness factor (CCF) using Steamate™ PAP7010 at an 885-MW US combined cycle equipped with a 395-MW steam turbine (Fig 2). Over a three-month period, CCF increased by 1.6%, and condenser backpressure was reduced by 0.6 in. Hg. This led to “improved condenser performance, lower fuel consumption, and (therefore) reduced carbon emissions.”

The study was based on research that suggests:

- The FFA investigated can enhance the performance of heat exchangers constructed of various metal surfaces by promoting dropwise condensation (DWC), and importantly,

- DWC may not be achieved if FFA levels in steam and on the surface are not properly balanced.

Closed cooling system

One presentation focused on FFS in auxiliary closed cooling-water systems in Israel. The presentation by Yitzhak Nussbaum, Ezom, discussed various components comparing traditional treatment versus FFS. This complex site contains many systems, equipment from many OEMs, many materials, and a wide range of piping sizes and velocities.

Previous application was NaNO2/sodium nitrite from 2015 to 2018. FFS began in 2018.

This detailed presentation concluded the following:

- FFS is a reliable anti-corrosion treatment in closed cooling-water systems.

- Working with FFS, especially in the early stages, requires patience and careful monitoring.

Food industry lab study

Discussing the food industry, Julia Jasper, Kurita Europe, addressed what she called the next generation of water treatment. Boilers in this industry have either direct or indirect steam contact to food, are either shell or watertube boilers, and traditionally use softened, RO, and demineralized makeup water.

Jasper’s presentation covered details of corrosion rates in condensate and boiler water during laboratory tests using coupons. Her predictions based on FFS laboratory experience:

- Reduced blowdown and water discharge.

- Energy savings.

- Protection against corrosion and scaling.

- Single-component product solution.

A related presentation, by Ricardo Valezquez, Fineamin, evaluated the effectiveness of Fineamin® 39F use in Mexico, highlighting advantages of the product specifically formulated for the food and beverage industry. This application is designed to prevent corrosion and buildup of scale in low-pressure, softened water systems.

Other industrial

There was an interesting presentation by Flow-Tech Chemicals (Israel) on the use of heat-recovery boilers in the fertilizer industry, and application of ODA-based FFAP in a combined-heat-and-power (CHP) facility.

The sulfuric acid plant (Fig 3) uses boilers and shell-and-tube heat exchangers to recover heat from the chemical process and provide steam to the plant. Occasional leaks in the heat exchangers allow acid into the steam/condensate.

A blend of OLDA and alkalizing amines had been in place for 10 years. Field trials on a change to ODA-based FFAP for two boilers (15 and 25 MW) took place in 2022. Results of this FFS change were presented based on conductivity, pH, and iron transport.

Initial testing showed a substantial reduction in iron concentration of boiler water, well-protected steam and condensate lines, and validation of lab simulations for reduced short-loop condensate conductivity. Both heat-recovery boilers are now transitioning to Odacon®, a film-forming amine product by Reicon.

Nuclear

NPP Cernavoda in Romania consists of two 700-MW CANDU-6 nuclear units commissioned in 1996 and 2007. Unit 1 plans a midlife component refurbishment project in 2026 to include reactor fuel channels, calandria tubes and feeder, and HP turbine internals.

Unlike similarly aged plants, NPP Cernavoda will not replace the steam generators, given the improved tube materials and increased corrosion resistance designed into these units. Outage duration will be between 24 and 30 months, carrying high risk of standstill corrosion adversely impacting non-alloyed and low-alloyed carbon steels.

General corrosion could be caused by the presence of water on surfaces of systems and components, and oxygen which may be diluted in water or be present by air ingress. Selective localized forms of corrosion (specifically, pitting) could also occur. There is also the threat of corrosion transport during subsequent operation.

The presenter, from Framatome, suggested that standard layup methods, both wet and dry, have limitations. Therefore, the site has chosen FFS technology.

A project roadmap was presented on incorporating FFS into other outage activities, looking at all components and subsystems of the primary heat-transport system and water/steam cycle, plus all linked standby and auxiliary systems. FFS will be included for the feedwater system, reheater stage section after the HP moisture separator, steam generators, condenser, and deaerator. Updates on this important project will be presented at a future IAPWS conference.

Steam turbines

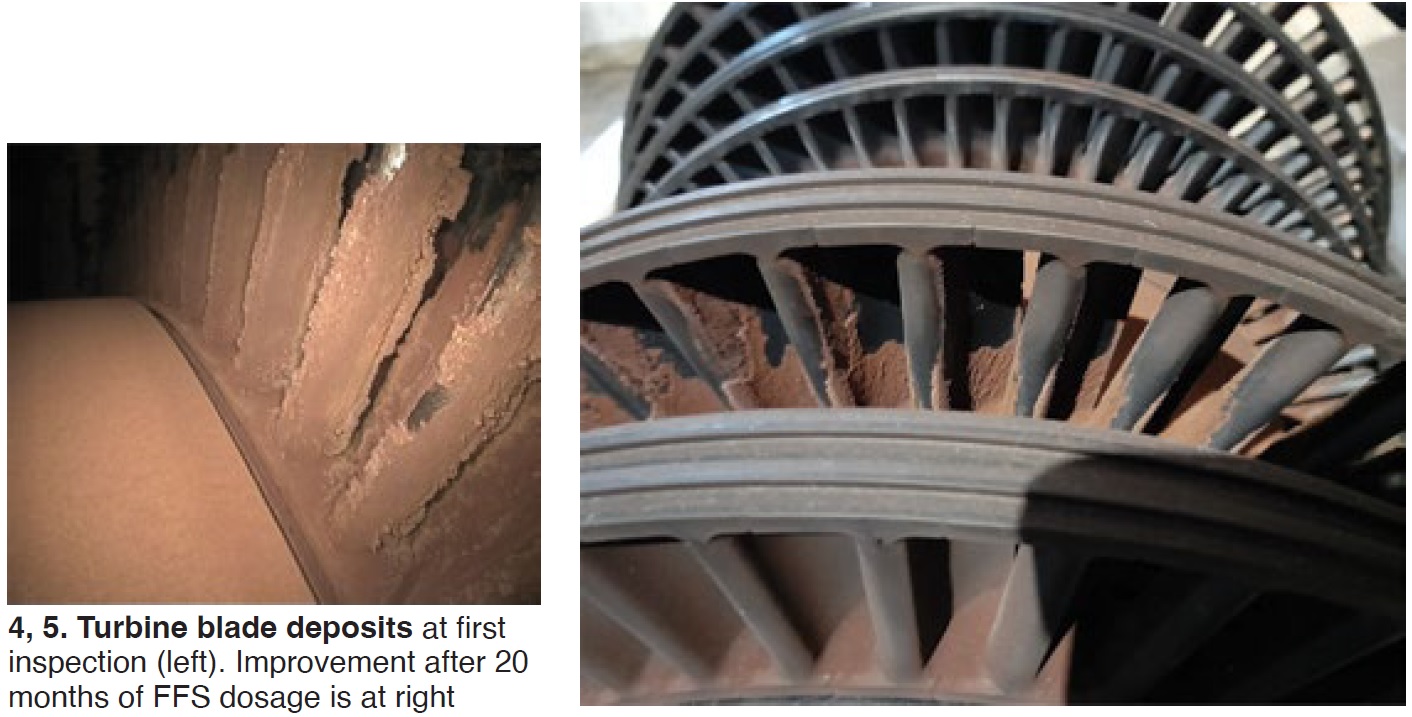

Jörg Kallweit discussed a biomass CHP plant in Luxembourg, highlighting its 8.4-MW turbine that was first examined and samples taken in 2020 (Fig 4). First option was online acid cleaning, second mechanical cleaning. However, the latter required turbine removal. A third option was online cleaning with FFS (amine-based FFA). Plant water treatment began in August 2022.

After 20 months, the following results were revealed:

Positive. Turbine output increased from 7.8 to 8.3 MW, with noticeable improvement in blade cleanliness (Fig 5).

Negative. An increase in acid conductivity in steam. The solution is to increase silica in the condensate. If conductivity remains high, boiler blowdown will be increased.

Some research details

Dooley explained in the conference launch that there is now a wide range of FFS products and mixtures from at least a dozen vendors globally. This increasing range makes research, derivation of common guidance, and solutions difficult. Most importantly, research is focused on the properties of adsorbed films.

Deni Jero represented a consortium from Université de Toulouse, Odyssee Environmental, Université Paris-Saclay, and Université de Bordeaux, for an in-depth look at adsorption kinetics in the presence of a reducing agent by electrochemical impedance spectroscopy. From the industrial perspective, the goal is to understand FFS barrier formation as a function of temperature in absence of corrosion products, and to provide a methodology for monitoring adsorption and corrosion kinetics.

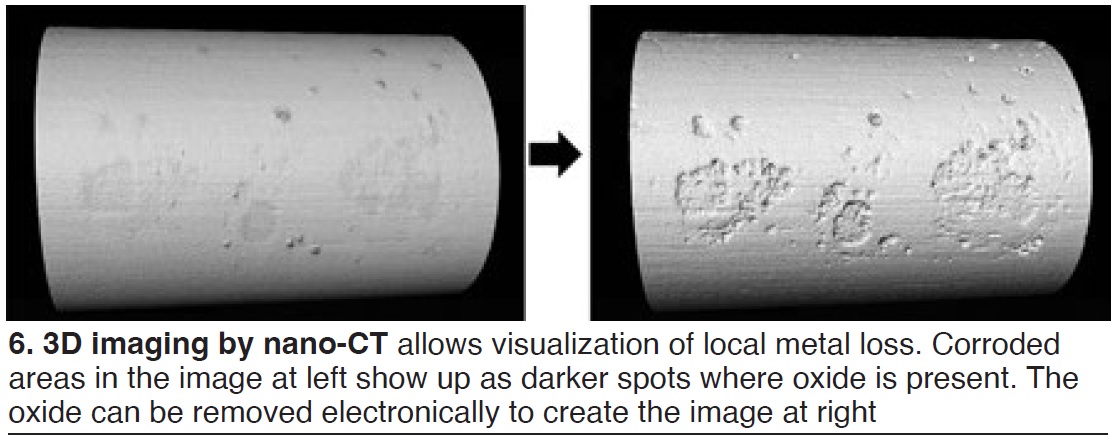

Andy Howell represented EPRI and gave details on tools that could characterize and evaluate the effectiveness of FFS in laboratory test projects—including scanning electron microscopy, X-ray spectroscopy, and other methods. He also discussed nano-computer tomography and analysis which can quantify local corrosion and visualize metal loss (Fig 6).

Universally, the presentations on applications of FFS to powerplants indicated reductions in the measurement of feedwater total-iron corrosion products. Some examples showed increase of CACE (conductivity after cation exchange). Mobilization of impurities (sulfate, for example) also was noted in some examples.

Scott Tucker, Hach, offered practical methods and best practices for monitoring iron-transport products and FFAs on a parts-per-billion basis, cautioning that “the lower you measure the more effect propagation of error will have on the results.” He added that “the sample is usually the greatest limiting factor in obtaining a true or representative result, especially at low-ppb values.” He presented Hach methods, equipment, and procedures with a focus on determining total iron.

Moving forward

On the third day, Thermal Chemistry’s David Addison began with a summary of the science and the unknowns, and a pathway to an IAPWS ICRN (IAPWS Certified Research Need) by the IAPWS Power Cycle Chemistry Group. When developed and issued, the ICRN hopefully will stimulate additional research related to FFS. See Dooley’s wrap-up analysis below.

Addison recapped the perceived and known benefits of FFS but was careful to point out the amount of work remaining.

Later that day, Wolfgang Hater (Germany) reiterated this with “Research needs for film forming substances applied in water/steam cycles,” tracing published research (primarily FFAs) back to the 1940s.

He summarized positive research developments by looking at these effects:

- Surface layers.

- Heat-transfer improvements in boilers and condensers.

- Droplet formation.

- Corrosion protection, copper and aluminum.

- Cleaning effect, mass transport.

- Ion-exchange resins, membranes (not yet conclusive).

He noted the remaining lack of reliable and conclusive data, suitable test concepts, and benchmarking.

Dooley’s wrap-up

In his review of the event, Structural Integrity’s Dooley included the following, pointing to the future publication of the ICRN by IAPWS. He stated:

“Overall and in the conference conclusion it was clear that the understanding of FFS application has improved worldwide since 2014 but that there is still a large amount of fundamental work needed to understand the mechanisms of the now wide array of FFS available for plant application. Up to now most research work has been addressed to ODA followed by OLDA; the secrecy associated with some of the FFP products remains an impediment for the industry.”

The following represents an outline of the research requirements which will be published in an IAPWS ICRN:

- Effect of FFS on growth mechanisms of Fe, Cu, and Cr oxides in water and steam. Better understanding will help to explain the effects of surface roughness and overdosing of FFS.

- Relation between surface coverage and degree of corrosion protection.

- Effect of FFS on boiler and HRSG tube failures (under-deposit corrosion and corrosion fatigue) and stress corrosion cracking.

- Film formation, kinetics, structure, equilibrium and stability (film thickness and porosity on water- and steam-touched oxide surfaces) for all FFS especially FFP.

- Thermolysis and decomposition products for FFA, and especially FFP, under oxidizing and reducing potential conditions.

- Uncertainty of adsorption onto oxide surfaces for all amine and non-amine FFS and how films are affected by other additions to the FFS. Characteristics of film layers and correlation with surface protection.

- Whether protection of superheated steam surfaces can be achieved for all amine and non-amine FFS.

- Increased steam-turbine performance for amine-based FFS (ODA) has been illustrated but research is needed to determine if FFS other than ODA reduce the surface tension.

- Can FFS improve steam-turbine efficiency and whether FFS, in general, can clean deposits from PTZ surfaces.

- Can FFS improve heat transfer in feedwater, boilers/HRSGs, and condensers.

- Impact of FFS on EDI and RO membranes.

- Impact of FFS on ion-exchange resins.

- Compatibility of FFS with other chemical additives (for example, chemical cleaning agents and dispersants).

- Relationship with any reduction of emissions.

FFS 2024

The FFS conferences are developed and supported by the International Association for the Properties of Water and Steam (IAPWS). FFS 2023 was arranged in Prato by Mecca Concepts (Australia) and the Combined Cycle Journal (US). The sponsors of FFS 2023 were Kurita Europe GmbH; Nalco Water, an Ecolab company; and Termanox Water Treatment Solutions.

Next year, the seventh FFS conference (FFS 2024) will be held March 26-28, also in Prato, Italy.

Contact Barry Dooley (bdooley@structint.com or bdooley@iapws.org) for further information on FFS and the IAPWS FFS conferences, or visit https://filmformingsubstances.com/ for more details.