With the 33rd annual meeting of the 7F Users Group less than a week away in Atlanta, we take a look back to its first meeting many moons ago to provide some historical perspective on the humble beginnings of what has become the world’s largest fleet of heavy industrial gas turbines (likely to hold that title for many more years) and the most attended user group for a single engine model. Now, imagine it’s 1991 and you are one of the very first owner/operators of a 7F gas turbine…

Getting started, 1991

Getting started, 1991

The contributions of users groups to the commercial success of gas turbines cannot be overstated. These machines are relative newcomers to the power generation sector of the electric power industry and without a proactive and collaborative user community, the development of today’s large, efficient, reliable, low-emissions gas turbines certainly would have taken longer than it has.

It is even conceivable that a utility industry dominated by large steam plants might never have embraced gas turbines as an alternative to coal-fired and nuclear central stations had the dedicated user “pioneers” not been so successful in helping the OEMs correct early design deficiencies.

Historical perspective. The first industrial gas turbine commissioned for electric generation, rated 3.5 MW, began operating at Oklahoma Gas & Electric Co’s Belle Isle Station in June 1949—seven decades after generators driven by steam engines first produced electric power at Thomas Edison’s Pearl Street Station in New York City.

For the next 15 years or so, gas turbines were pretty much viewed as a novelty by regulated electric utilities, which produced about 90% of the nation’s electricity until deregulation of generation began in the 1990s. Prevailing attitudes on the value of gas turbines in an integrated electric system began to change following the Northeast Blackout in November 1965 when they helped boot-strap the grid back into operation. Until that time, gas turbines primarily were associated with non-critical peak-shaving applications.

One result of the blackout was a run on black-start units—mostly General Electric Frame 5s and Pratt & Whitney FT4s. That first market bubble lasted into the early 1970s, raising the profile of gas turbines and stimulating the development of larger machines. The design effort on GE’s Frame 7 series of engines began about a year after the blackout and the first unit was installed as the 1970s dawned. The MS7001A had a 1650F firing temperature and was rated 47 MW—about three times the output of the latest-model Frame 5s offered at that time.

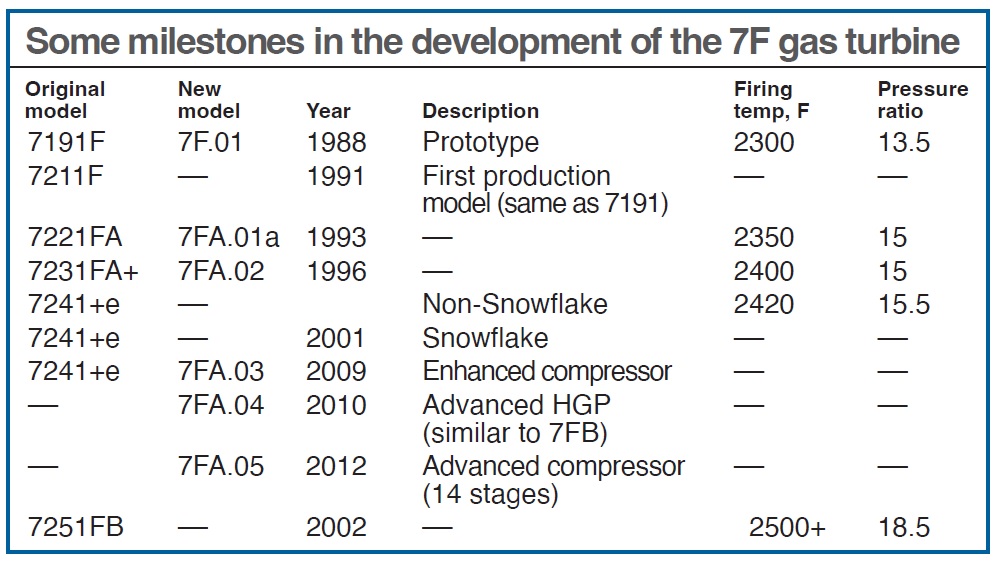

Design development and market acceptance of the Frame 7 product line proceeded rapidly. The nominal 75-MW 7E was introduced with a firing temperature of 1985F only 10 years later (1980). An even bigger step was taken in the ensuing decade. The first F-class machine, rated 147 MW and having a firing temperature of 2300F, shipped to Virginia Electric & Power Co’s (Vepco) Chesterfield Power Station in 1988; christened Unit 7, it was declared commercial in June 1990. Sister unit Chesterfield 8 began commercial operation in 1992 (May), the year the 159-MW 7FA was introduced with a 2350F firing temperature. Some early design improvements in the MS7001F that followed are summarized in the table.

When the 7F Users Group conducted its first meeting in November 1991, Chesterfield 7 was the only F-class machine running in the US. It had 9000 hours of operating experience. Four utilities were represented at that forum in Baltimore: Vepco, Baltimore Gas & Electric Co (BGE), Florida Power & Light Co (FPL), and Potomac Electric Power Co (Pepco). There were 14 attendees.

The meeting began with short reports by the utilities. Each had at least one gas turbine on order, with expected commercial operating dates ranging from June 1992 into the late 1990s (no specific year). Interestingly, all engines would have dual-fuel capability and only two of the nine gas turbines planned would be used in simple-cycle service.

The opening status reports indicated that two of the participating utilities were repowering existing steam plants to form their combined cycles. Also, that two companies were planning to install diverter dampers on their GTs to maximize operating flexibility. The first 7FA going into service would be equipped with dry, low-NOx combustors because of emissions restrictions where that plant was to be located. Gas turbine controls would be either Mark IV or Mark V; DCS systems were from Westinghouse Electric Corp, Foxboro Co, and Honeywell Inc.

Of considerable interest to attendees was the Vepco report on Chesterfield 7’s operating experience. Learning from the experiences of colleagues can save time and money, so this information was of particular value to anyone with a unit on order. For the first meeting that meant everyone in attendance.

Chesterfield 7’s performance numbers were positive. For example, the equivalent availability of the prototype engine since COD was 85.79%. Two clarifying points: The unit was “out of the money” for about half of its 3500+ non-operating hours. Importantly, half the hours Chesterfield 7 was out of the money, the fuel-gas compressor was unavailable, and the high cost of alternative oil was the reason for it being uneconomic to operate the unit.

The speaker noted, in particular, the unit’s run from the beginning of April until the end of October (1991) when Chesterfield 7 was dispatched right behind the nuclear units and ahead of all coal units—including three mine-mouth operations. The message was clear: F-class gas turbines were competitive mainstream generation assets right out of the box.

Compressor fouling and how to deal with it is a subject discussed at most user-group meetings. Vepco engineers reported no load degradation on Chesterfield 7 based on weekly performance tests. The unit was not equipped to perform online water washes and offline washes had been done only three times since COD. Interestingly, one of the utility participants had specified a coated compressor rotor for its gas turbines; the Chesterfield 7 compressor was uncoated.

Specific issues mentioned in the Vepco presentation essentially were of two types:

- Manufacturing and field errors/oversights unrelated to new technology—such as a generator rotor shipped from the factory with shorts in it and metal shavings found in the steam turbine because of an inadequate steam-line blow.

- Challenges presented by the higher gas temperatures and pressures associated with F-class technology and cycling operation, such as loss of turning vanes and cracking of vent piping in the heat-recovery steam generator (HRSG).

Engine vibration on startup and wear and tear on exhaust thermocouples were two more subjects that received meaningful discussion time. In its first year and a half of operation, Chesterfield 7 lost an average of one exhaust t/c daily; the unit has 27 thermocouples.

Over the last three decades the operating paradigm of the combined-cycle fleet has changed dramatically: Engines have gotten larger, firing temperatures hotter, emissions regulations more restrictive. Yesterday’s solutions generally are not adequate for today’s cycling regimen and higher gas temperatures and flows. Challenges persist and new solutions are necessary. A user group’s work is never done.

The maintenance session at the first meeting reflected very orderly utility thinking on overhauls in the days before deregulation and OEM long-term service and parts agreements. It’s an interesting contrast to the factors and formulas owners are governed by today. A Vepco participant noted that combustion inspections had been based on a yearly schedule and that was going to change to an 18-month interval because Chesterfield 7 was being dispatched fewer hours than originally thought.

One of the other utilities offered a firm schedule for maintenance outages based on best available information from the OEM. It called for an 8000-hr interval between combustion inspections, 24,000 hours between HGP inspections, and 48,000 hours between majors. The speaker noted that the company had developed a schedule that predicted parts replacements and refurbishments for 30 years. Recent meetings have reflected dramatically different maintenance schedules.

Here’s what was the1991 thinking on combustion inspections: A five-day outage would be sufficient with new spares on hand for immediate replacement. If reconditioning of parts was necessary, extend the outage by two weeks. A typical CI at Chesterfield 7 called for up to eight persons per shift—six working on the combustors, the others handling miscellaneous work items.

Learning on the job. Cracking of nozzle tips at around 4000-5000 hours was one of the early problems at the first Frame 7 plant, thereby preventing Chesterfield 7 from achieving its desired CI interval. One of the first lessons learned was that all fuel nozzles are not created equal. Station personnel did not realize the OEM balanced the entire set of 84 nozzles to optimize machine performance until they swapped out cracked nozzles with new ones and experienced higher-temperature exhaust spreads.

Unit operation. Vepco shared with the group its startup procedure, which took about an hour when the gas turbine was cold: Fire the GT, synchronize at 10 MW, match boiler steam and turbine metal temperatures prior to rolling the steamer. Gas-turbine ramp rate was 8 MW/min.

Transferring from gas to oil at full load was no problem, the representative said. It took about two and a half minutes to complete. However, switching from oil to gas was more difficult and required up to about twice as long for a successful transfer than going from gas to oil. Speaker said the gremlin probably would be found in the regulator in the gas main—possibly the valve was too small or its response time too slow. On a gas-compressor trip, the unit flamed out before the transfer to oil could be completed.

“Comparing notes” is a big benefit of user-group participation. One participant began talking about the two atomizing-air coolers provided with his package for redundancy. Someone else said GE had eliminated the second cooler in their package. Interesting, because there really did not appear to be sufficient operating experience to support such a decision. Why not err on the conservative side so early in the lifetime of F-class units? First participant jumped back into the conversation noting that the OEM had not run separate drains off the coolers and cautioned against linked drains. Ganging of drains is well known for causing major issues on HRSGs.

Thermal shock in steam-turbine bypass lines was recognized as a potential problem at the dawn of F-class units. One utility avoided the possibility of this occurring by maintaining steam flow through the bypass at all times.

Sharing is a big part of the user-group value proposition. Every plant needs procedures—startup, operations, and maintenance. The three utilities that soon would be starting up their first F-class units acknowledged a desire to work collaboratively in the development of procedures not yet available. An action item taken was for each of these companies to develop a list of procedures available together with a list of those still required and by when.

Then the participating utilities agreed to extend an openness toward helping each other develop construction and startup schedules as well as cost estimates. Finally, a master contact list was developed with names, titles, and phone numbers (email came later) of people at every project with responsibility for scheduling, cost control, procurement, engineering, and general project information.

Staffing and personnel development and training generated significant discussion as you might imagine. It takes years of experience with a new engine model to right-size your staff. Today, 7FA owner/operators may be running their plants with 20 or fewer permanent personnel and would chuckle at the thinking in 1991—before deregulation, as noted earlier.

One of the utilities had six people on a shift for two 1 × 1 combined cycles; another planned to have four per shift (2 × 1 arrangement) and was considering a maintenance staff of 40 to 45. A utility planning two 2 × 1s focused on five operations shifts of four people for each unit and 40 to 45 total staff for the first combined cycle and an additional 15 to 25 when the second unit was completed.

Closely related to the then-and-now staffing comparison is personnel training. During a discussion on that topic one participant noted that his company had a training program for operators that ran 39 months. That was typical for regulated electric utilities back then. At user-group meetings in the deregulated era you often hear considerable angst over the retirement of senior personnel and the lack of suitable candidates to fill open positions.

One reason for the shortage of qualified operators, electricians, instrument techs, mechanics, etc, is that small independent power producers don’t have the financial resources or the time—and in some cases, the inclination—it takes to develop personnel qualified to operate and maintain today’s high-tech turbines. It is not unusual for some investors to flip their generation assets in less time than it would take to train a qualified staff.

As the first 7F Users Group meeting closed, it’s reasonable to assume no one in the room could have imagined that three decades later:

- The organization would still be in existence and that its annual conference and exhibition would have grown to become the world’s largest venue for F-class technology and business discussions.

- Three of the four utilities represented at the meeting would no longer be in the business of electric generation under the names they had in 1991.

- Unregulated generating companies, which did not exist in 1991, would control about half of the nation’s power-production capability and more than 60% of all gas-turbine-based generation.

- One of the 1991 attendees would participate in the 20th anniversary meeting and two participants would be serving on the steering committees of other gas-turbine user organizations at that time. Continuity of technical leadership is vital to progress. That’s service user groups like the 7F provide the electric power industry at no cost.

End note. Only one of the participants in that first 7F meeting is still active in the industry, based on CCJ research. The well-respected Pierre D Boehler, employed by Pepco at the time, is now senior SME (subject matter expert) for gas turbines in NRG Energy’s Engineering & Technical Services Group—the result of mergers that absorbed plants and people from GenOn, Mirant, and, of course, Pepco. He provides technical support for a fleet of GE and Siemens Energy units, ranging from aging Frame 7s to late-model F-class engines, on matters concerning maintenance overhauls, operating issues, upgrades, etc.