By Vignesh Bala, Vogt Power

Editor’s note: This is the first of three articles exploring the impacts of gas-turbine upgrades on heat-recovery steam generators (HRSGs). It examines the driving factors behind GT upgrades. Part 2 will focus on the concept of “re-rating” the HRSG after its upgrade. Part 3 will address implementing the HRSG mods onsite and the associated planning considerations.

Gas-turbine upgrades are becoming more prevalent due to a confluence of factors. There are three primary drivers behind upgrades. They are: growing demand for power generation, optimization of efficiency and heat rate, and flexibility or low-load operations.

Growing demand. The US experienced little growth in net demand for electricity between 2007 and 2017. Although there was a need for more power, efficiencies resulting from technological improvements accommodated most of the net growth in demand and consumption.

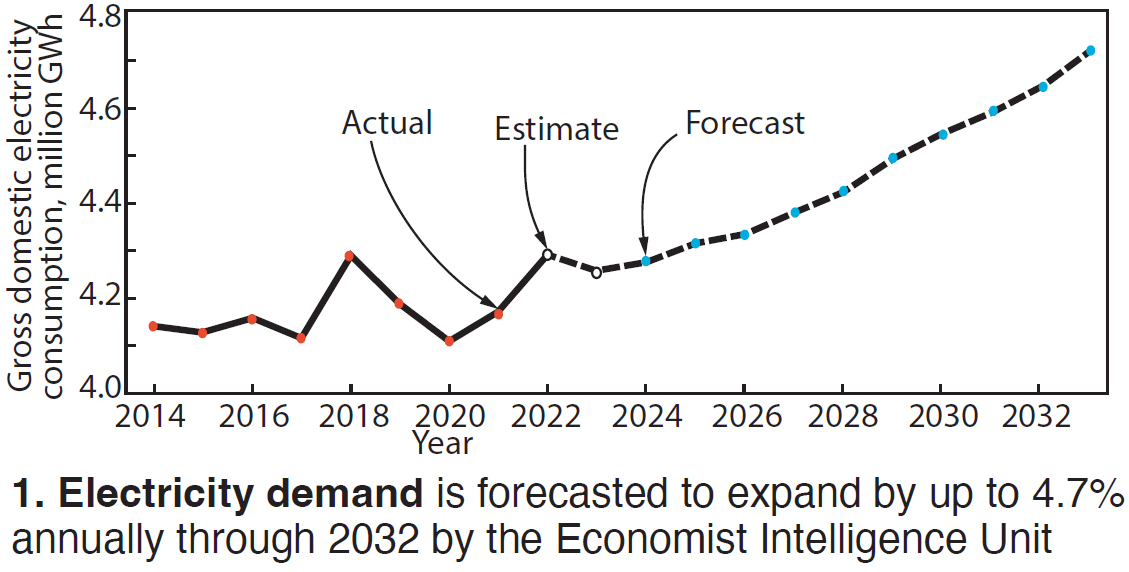

This has changed in the last five years, with the demand for electricity forecasted to expand by more than 4.3% annually over the next eight years (Fig 1). This growth is driven by data centers, cryptocurrency, the expansion of domestic industrialization, and proliferation of electric vehicles. More concisely, the demand for electricity in the form of “final energy” is increasing. By boosting the capacity of existing combined-cycle assets through GT upgrades, companies can increase generation with minimal economical and operational impact.

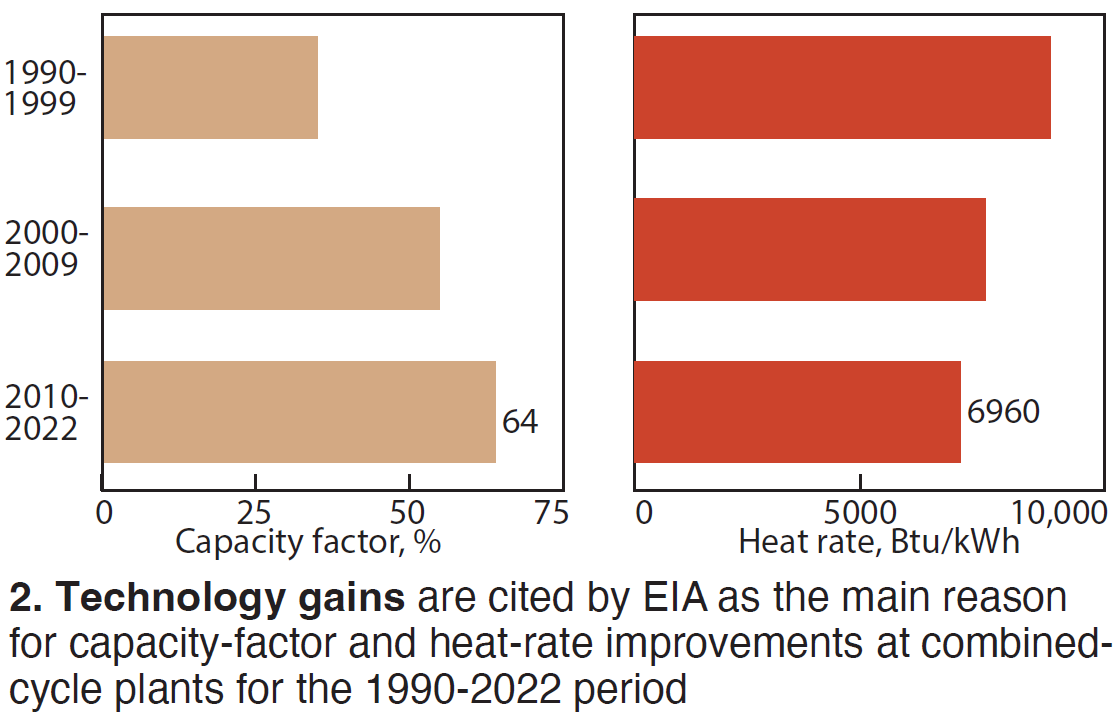

Increasing efficiency. In deregulated merchant states, power producers are burdened with fuel cost and motivated to find ways to maximize efficiency. Turbine upgrades are a good tool for increasing efficiency while boosting output at affordable cost and with minimal impact to operations. As GT efficiencies and heat rates improve, combined-cycle gas-turbine (CCGT) plants can produce more power at less cost. Fig 2 shows capacity factors have risen significantly since 1990, in part through GT upgrades.

Flexible or low-load operation. Renewable generating resources may cause CCGT plants to cycle (shutdown/restart) multiple times daily. Cycling is an inherently slow process and can increase the fatigue experienced by the unit and its components. Vogt Power’s field experience and customer feedback point to premature cracking and failure of pressure-part components, such as HP drums and superheaters.

To mitigate fatigue, GT upgrade packages are used to allow plants to operate at a very low load. This is a popular choice as operators decide how to best use their equipment to match demand and reduce the time need to ramp the GTs.

Many plants are performing GT upgrades because of the factors discussed above. However, the impacts of GT upgrades on the HRSG and the rest of the combined-cycle plant cannot be ignored because upgrades can result in significant changes in GT exhaust flows and temperatures. A detailed study is required to quantify the impacts of a GT upgrade on the HRSG and balance of plant. Regarding the HRSG, the impacts of GT upgrades can be classified into two categories: pressure parts and non-pressure parts.

Pressure parts impact the feasibility of the upgrade; therefore, this is a primary focus. The associated pressure parts most often affected are these:

- Superheaters and reheaters. The increase in HRSG exhaust temperature can mean higher operating temperatures for tubes and headers, and may exceed the design temperatures of these components. This can occur during low-load operation when exhaust-gas temperatures typically are high and exhaust-gas flows are low. Result: Low steam production at high temperature. This can be problematic because high temperatures increase tube operating temperatures and low steam flows mean less cooling flow to reduce the operating temperature.

- The economizer sections should be analyzed to ensure there is no steaming in them because of the GT upgrades. Steaming can disrupt flow through the economizer sections due to vapor lock. During low-load operation, low water flow through the economizer can cause buoyancy issues. These typically occur in downward passes of the economizer where velocities are very low (less than 2 ft/sec).

Furthermore, during low-load operation there also can be issues with the distribution of water within the header: Water sometimes flows to tubes directly below piping connections instead of being distributed through the header. This can result in some tubes operating with very little or no cooling flow and hence expanding differently than tubes with flow, thereby causing undue stress on tube-to-header welds. - If exhaust flows increase because of a GT upgrade, drum internals must be evaluated to ensure there are sufficient cyclone separators and/or chevrons for steam/moisture separation. Undersized drum internals can result in moisture carryover into the superheater, which can quench and damage the tubes. Note that carryover also can cause undesirable steam-turbine deposits.

If exhaust flows increase significantly because of the GT upgrade, drum retention time also must be evaluated to ensure there is no risk of the evaporators running dry during an upset condition. - The need for attemperation can change significantly if a GT upgrade results in higher exhaust-gas temperatures. Analysis is required to properly size the control valve for the new range of flows. If increased attemperation flow is needed, the type of attemperators in operation (probe versus ring type), as well as downstream straight-length requirements, also must be analyzed to ensure there is no moisture carryover into the downstream superheater tubes (Fig 3).

- Safety relief valves may require replacement if the design pressure of the system is increased and the entire system is “re-rated.” New safety valves also may be necessary if there is a significant increase in steam flow because of the GT upgrade.

GT upgrades often are performed to increase plant capacity or efficiency and these result in increased GT exhaust flows and temperatures which, in turn, increase steam flows. In a sliding-pressure unit, the higher steam flows result in higher pressures. Units with supplementary firing may require limits on the maximum firing rate so the maximum design pressure of the system is not exceeded. While these measures allow implementation of the GT upgrades without needing system re-rates, such firing limits also curtail power production and must be considered when evaluating the total capacity increases of GT upgrades.

Regarding non-pressure parts, the following also could be affected by GT upgrades and should be inspected periodically:

- Liners in the diffuser duct and inlet duct are sometimes damaged after a GT upgrade—especially if there are significant changes in flows or exhaust-gas profiles.

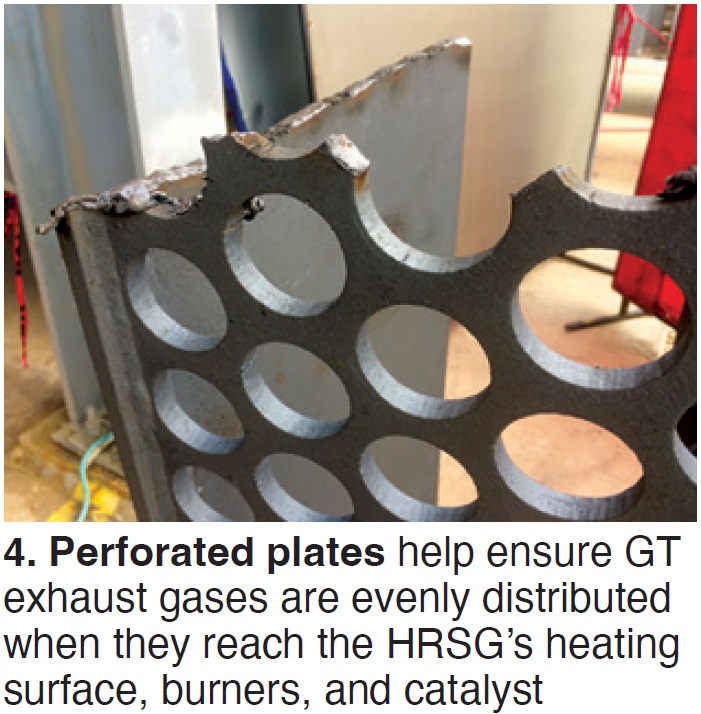

- Distribution grid (a/k/a perforated plate) helps ensure GT exhaust gases are distributed evenly when they reach the HRSG’s heating surfaces and burners, and catalyst. However, a GT upgrade could change the exhaust-gas profile or flow rates, which can damage the grid (Fig 4).

- The temperature of the exhaust stream at the catalyst could change because of a GT upgrade. This could affect catalyst reactivity and should be analyzed.

About the author

Vignesh Bala is VP HRSG Services at Vogt Power, a Babcock Power Inc company. He leads a group providing cutting-edge analysis and retrofit solutions for combined-cycle powerplants to increase capacity and reliability in support of a changing power market. Bala and his team conduct studies, inspections, and turnkey retrofits, and provide parts for HRSGs manufactured by all OEMs.