Related Links

- What you shouldn’t miss at the upcoming Power Users Annual Conference featuring five user group tracks

- Power Users Annual Conference dives deep into emerging industry trends, concerns

- Combined Cycle Users Group: 2023 vendor presentation recaps

- Steam Turbine Users Group: 2023 vendor presentation recaps

- Generator Users Group: 2023 vendor presentation recaps

- Power Plant Controls Users Group: 2023 vendor presentation recaps

“Generator Stator Endwinding Tutorial,” Howard Moudy, National Electric Coil

Because endwinding reliability has been a source of concern for decades, the refresher offered here should never go out of style. Covered are function of endwindings; design, material, and process considerations and alternatives; sub-components; vibration and harmonics; bump testing; corona protection; and a case study of a harmonic-induced failure. Author stresses, the endwindings should “take a licking and keep on ticking.”

“Generator Monitoring,” Bill Moore, EPRI

“No other ‘non-essential’ sensor gives more information for so little effort and money” than the flux probe, insists author, who covers essential, “for-cause,” and online monitoring options. EPRI’s Generator Health Assessment Tool, which culminates in a weighted risk score for the unit, can assist with the latter.

“Stator Endwinding Impact (bump) Testing and Mode Shape Analysis,” Jason Sinkhorn, EME Associates

Topics addressed include: Consequences of resonance in endwindings; fundamentals of vibration; forcing function and response; end turn, phase lead, and global end basket testing; and addressing undesirable test results.

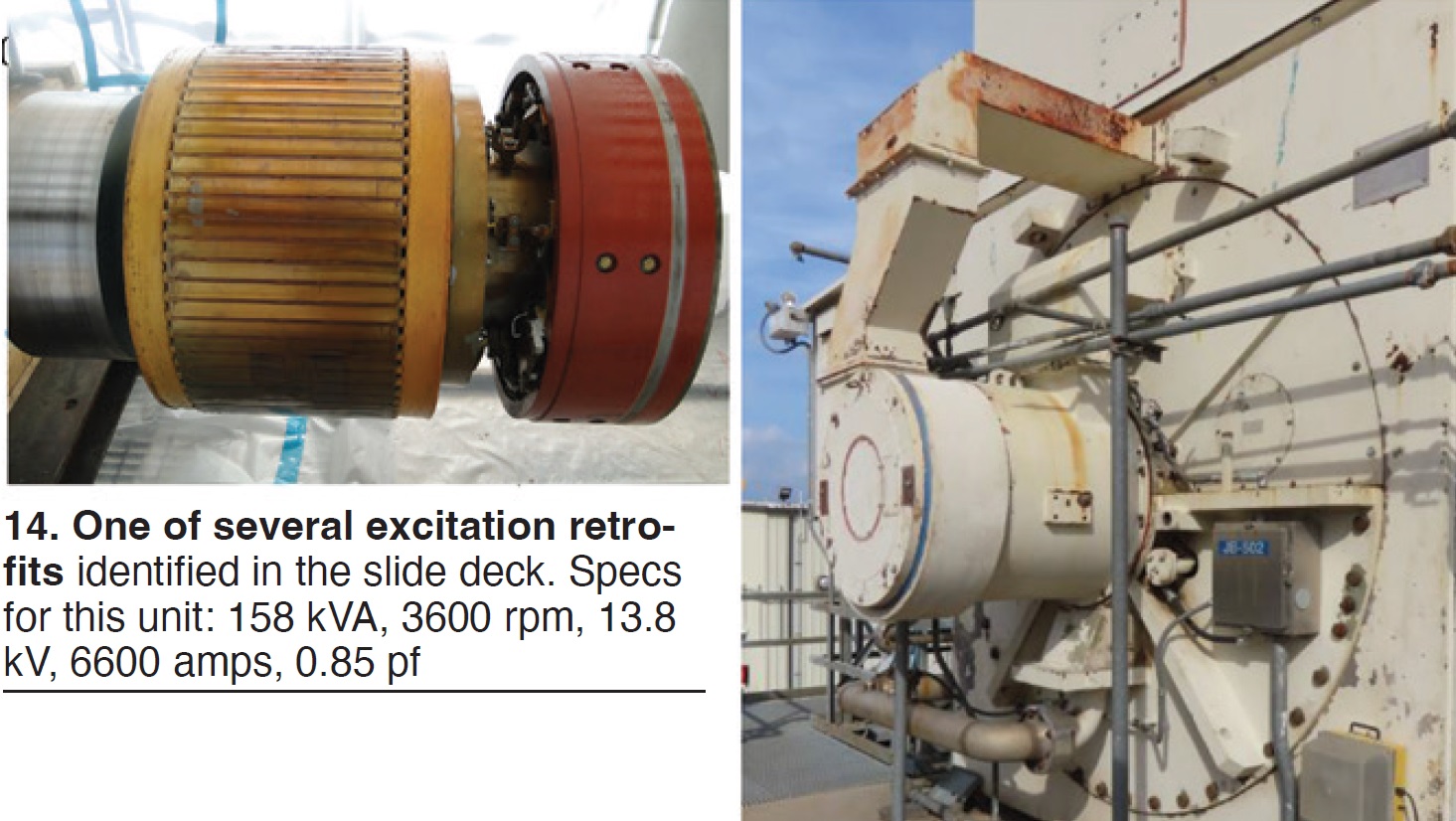

“Brushless Excitation System Overview,” Jacques Leger and Danny Besmer, Electric Machinery/WEG Group

Theory, design, construction techniques, failure modes, and testing methods are reviewed (Fig 14), with ample illustrations and graphs. Last twelve slides are a pictorial of excitation system retrofits and summary of benefits obtained.

“Advances and Case Studies on EMI Monitoring,” Kent Smith, Cutsforth

After some basics on, and rules of thumb for, electromagnetic interference (EMI), heart of the presentation are a description of the legacy continuous EMI monitor, the Cutsforth EMI Versions 1 and 2 (the latter including InsightCM), latest innovations, and case studies for a generator/transformer and a generator/exciter cable.

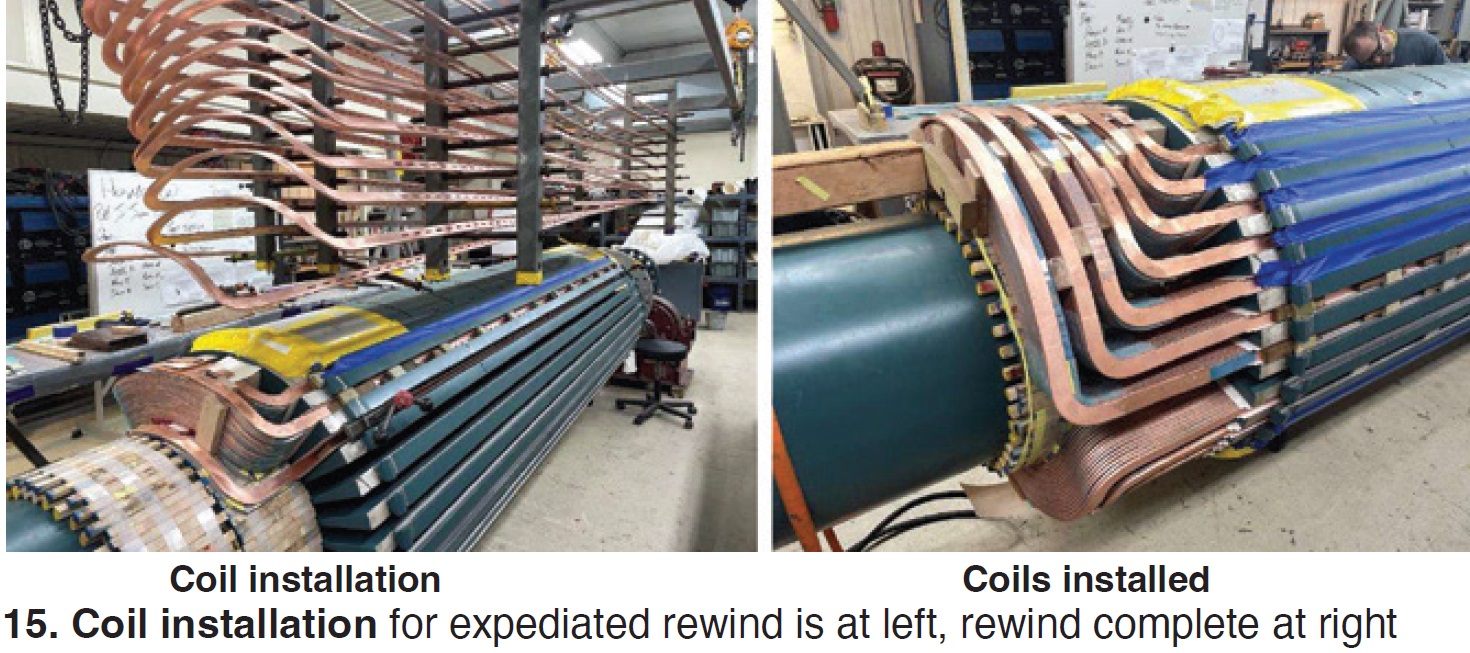

“7A6 Field and Stator Expedited Repair Solutions,” James Joyce, MD&A

Meat of the presentation is an illustrated journey through the rewind of a generator (Fig 15) with dozens of shop photos.

“Turbo-Generator Rotor Rewinds: Maximize the Value of Maintenance,” Rob Rettler, Toshiba America Energy Systems

Why rewind your generator? That’s the question addressed to kick of this series of slides, which then covers considerations in project scope, NDE (especially rotor-coil retaining rings), conductors, insulation materials, and final testing and verification.

“Generator Field Issues: Thermal Sensitivity and 9A4 Bore Copper Looseness,” Jamie Clark, AGT Services

Bulleted scope considerations for standard field and stator testing make up the first slides, followed by details for field vibration and thermal sensitivity indicators and testing; a case study involving a GE 6A2 unit—including rating info, O&M history, and photos of internals, ventilation provisions, shorted turn, contamination under retaining-ring insulation (Fig 16), block displacement, and other findings; and ending with dramatic photos of a field ground caused by loose bore copper connection and repair.

“Generator High Speed Balancing Case Studies,” Keith Collins, MD&A

Included here are general characteristics of balancing, component balancing (including the often-forgotten collector end balance cap), operational speed testing, and “the case [study] of the speed-induced short.”

“Generator Rotor Concerns,” Howard Moudy, National Electric Coil

Contamination and moisture contamination are two of the concerns mentioned, but the slides’ core material is focused on distress from speed and load cycling, with a photo-driven case study of damage areas and subsequent repair.

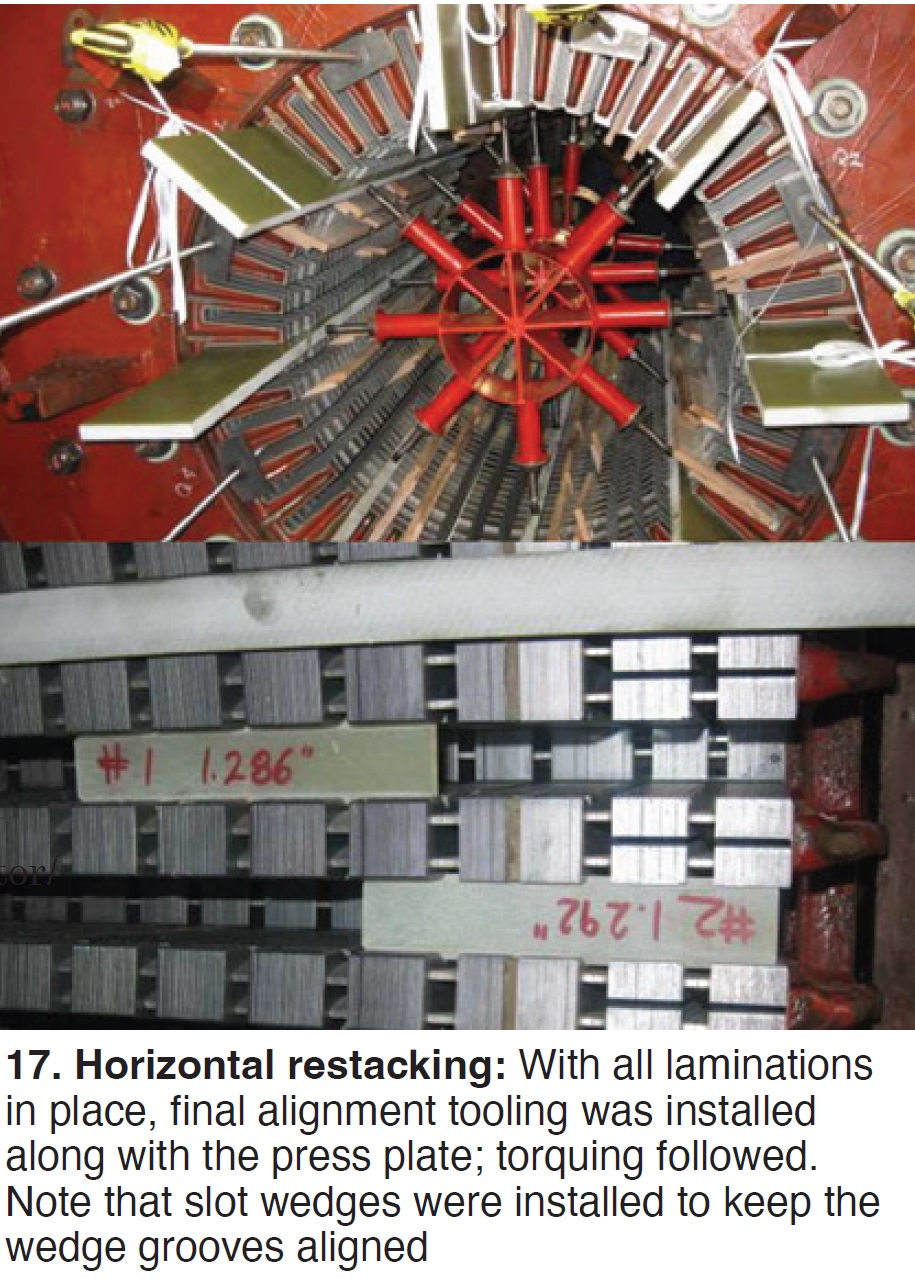

“Core Restacking in the Horizontal Position,” Antonio Flores, EthosEnergy Generator Services

The original scope for a 38-MW Westinghouse air-cooled generator (outdoor unit) was testing and inspection, but after multiple hot spots were identified and corrective measures proved unsuccessful, decision was made to conduct an innovative full-core horizontal restacking. The photo journey comprises the balance of the slides. Notable are the new core-support tools manufactured to complete the project (Fig 17).

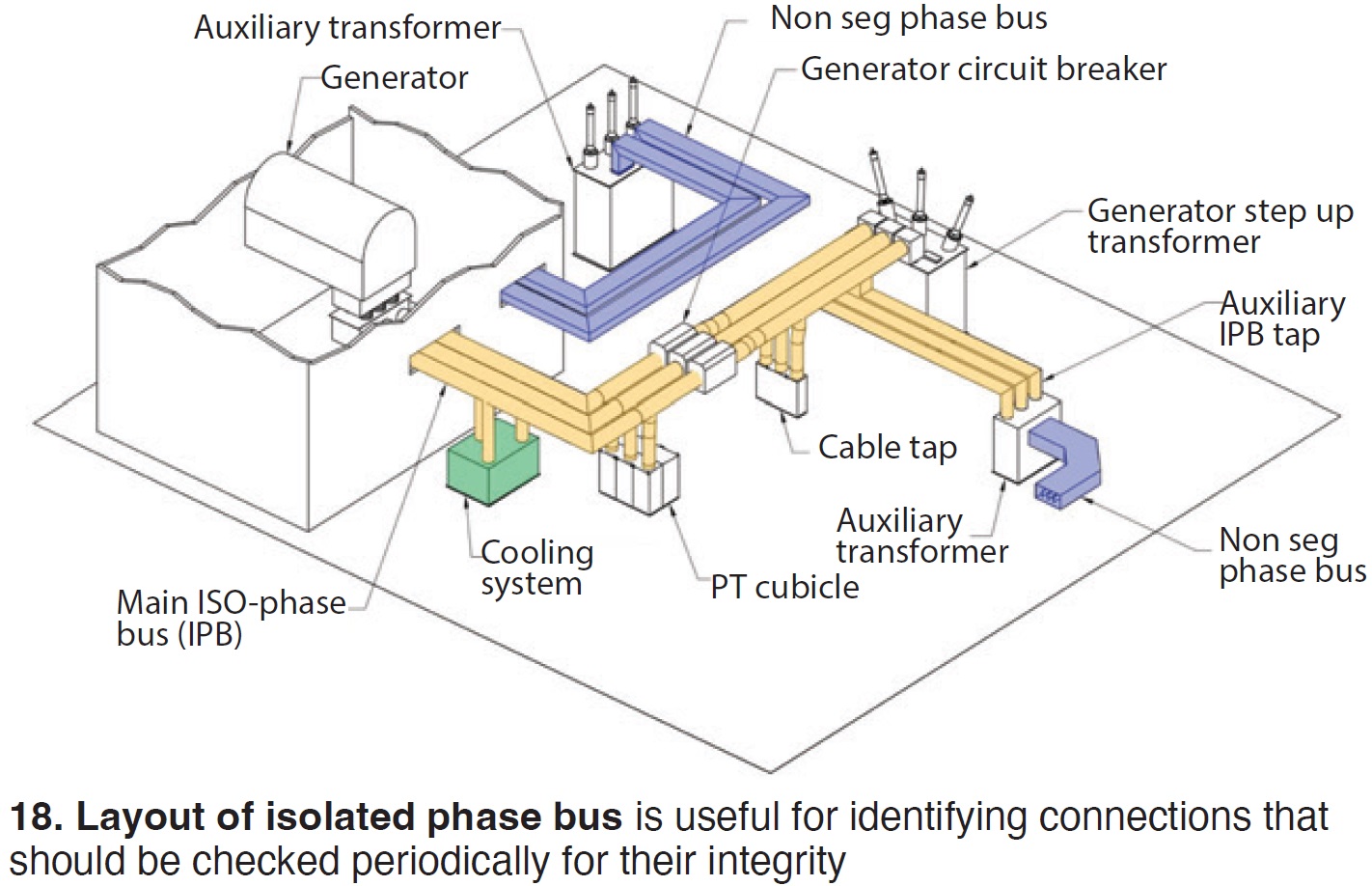

“Isolated Phase Bus Circulating Currents and Overheating Issues,” Mohsen Tarassoly, Electrical Builders Inc

Isolated Phase Bus design and construction basics are reviewed, then causes for overheating are listed, especially for bolted connections at major equipment terminations. Circulating currents caused by damaged or degraded component also lead to overheating. Maintaining the integrity of the original design (Fig 18) and appropriate grounding are two good ways to avoid overheating.