By Clyde V Maughan, Maughan Generator Consultants (retired)

This historical perspective on turbine-driven generators, in four parts, is based on Clyde Maughan’s recollections from a 72-year career in turbine/generator design, manufacturing, and service—half that time with General Electric Co, the remainder as an independent consultant.

Having joined GE in 1950, and having worked closely with the “old timers” of that day, his direct knowledge base goes back into the teen years of the 1900s—a span of over a century. No guarantee is offered that all the information is exactly correct, but the essence should be acceptably close to give a general understanding of the difficult evolution to the present designs of generators.

Having joined GE in 1950, and having worked closely with the “old timers” of that day, his direct knowledge base goes back into the teen years of the 1900s—a span of over a century. No guarantee is offered that all the information is exactly correct, but the essence should be acceptably close to give a general understanding of the difficult evolution to the present designs of generators.

Because the major OEMs of the day kept pretty close (informal) watch on each other, the industry was generally well informed on the designs, and troubles, of each. Thus, the information here on non-GE machines should be reasonably accurate.

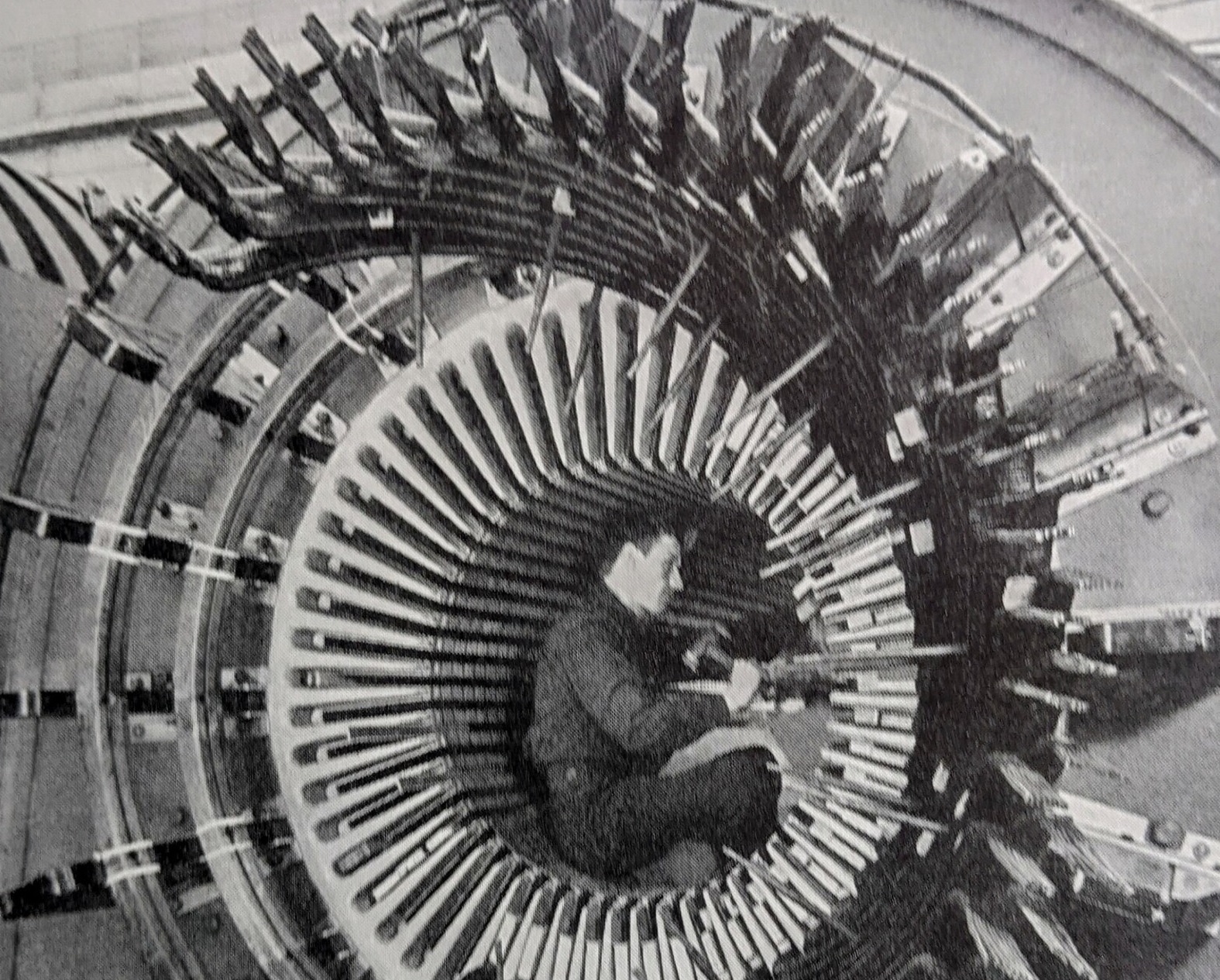

The focus of this article is on the materials and structural configurations, and associated service issues, of generators installed from about 1960 onward, with little insight provided as to why specific materials were selected or why the configurations were needed.

This information should be of particular value to owner/operators of GE Frame 5, 6B, and 7B-EA gas turbines, some of which date back to the late 1950s, as well as to users at combined cycles equipped with steam turbines repowered from mid-century coal-fired powerplants.

Summaries of recent presentations by owner/operators and vendors at meetings of the Generator Users Group, as well as of the Steam Turbine Users Group, the Combined Cycle Users Group, and the organizations serving the legacy Frame 5, 6B, and 7B-EA GE gas turbines are only a mouse click away in CCJ No. 71.

Generators Table of Contents

Intro: Generators, a brief history

Part 1: Electrical insulation systems

Part 2: Winding support systems

Part 3: Generator cooling methods