By Jamie Clark, AGT Services Inc

A relatively common major repair encountered by generator owner/operators is replacement of the stator winding. There are two general methods for designing/constructing stator windings. They are:

- Conventional: It uses stator bars that are fully impregnated with resin and the resin is fully cured. The assembly materials—for example, fillers and wedges—are dry, thus there is no bonding between the slot contents and the stator iron.

- GVPI (global vacuum pressure impregnation): It uses stator bars on which the groundwall is “dry”—that is, essentially mica tape with no resin material applied. The wound stator is then placed in a large tank where a vacuum is applied to remove all moisture and air from the groundwall. Next, the tank is filled with resin and pressurized to force saturation of the groundwall with resin. Finally, the stator is removed from the tank and placed in an oven to cure the resin. With this system there is strong bond between the slot contents and the core iron.

There is a third type of winding sometimes used that is “almost” conventional versus GVPI. It is intended to reduce material and labor costs in the factory, but it does not consider repair complexity in the powerplant. In this system, the bars are installed fully cured, but there is a saturated “wet” filler in the bottom of the slot and between the bottom and top bars.

Additionally, during the stator wedging process, another layer of saturated felt is installed under the wedges. After baking, the excess resin in the wet fillers fully bonds the slot content to the core iron and the winding behaves as if it were GVPI’d. Adding wet filler beneath the stator wedges makes routine stator rewedging more complex and actually increases the risk of top-bar insulation damage. But that’s a topic for another time.

The replacement procedures for a conventional winding are well understood and straight forward—and stator rewinds have been routine for about a hundred years. GVPI windings became common on large generators recently, and because removal of a bonded winding tends to be very difficult, standard removal procedures have not yet been developed.

However, AGT has successfully rewound several stators with GVPI windings, and described its procedure for winding removal at the 501F Users Group’s 2020 Conference and Vendor Fair, last February, at the Hilton in West Palm Beach, Fla. A summary of that presentation follows:

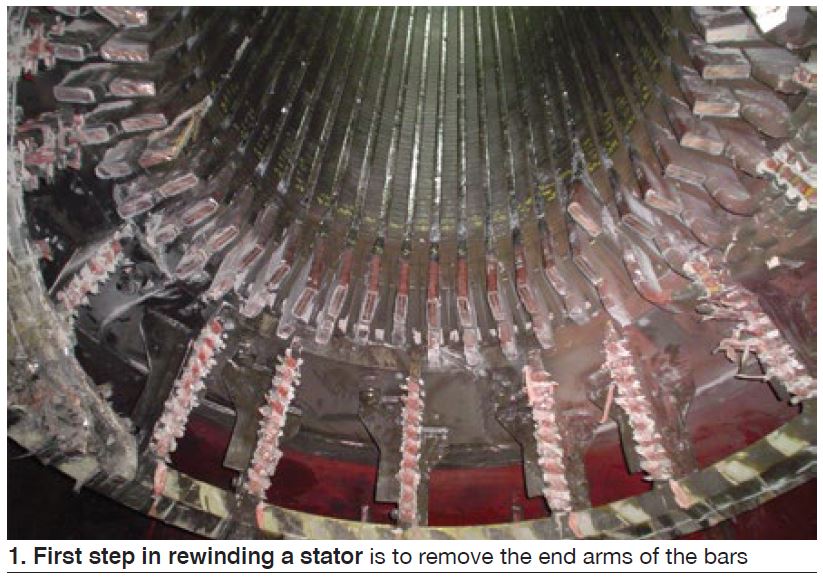

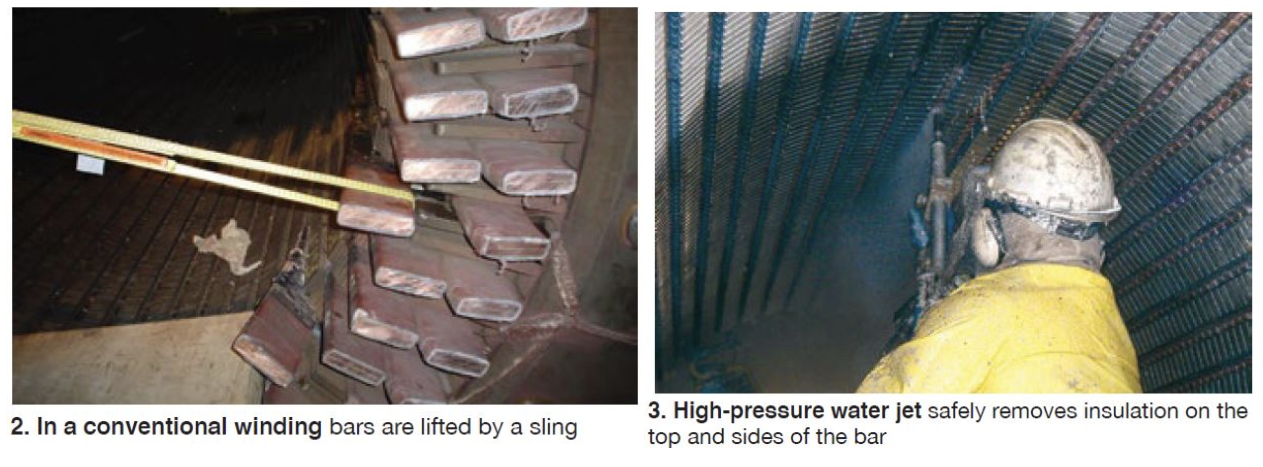

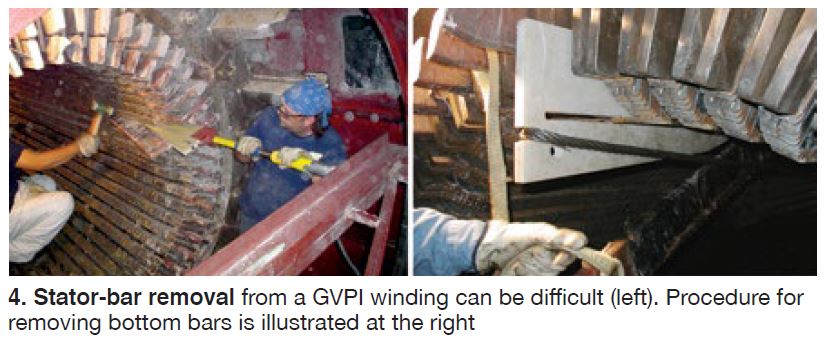

The first step is removal of the end arms of the bars (Fig 1). In a conventional winding, bars are lifted by a sling (Fig 2). But with a GVPI winding this succeeds simply in kinking the bar near the core end. However, it has been found that the insulation on the top and side of the bar can be safely removed using a high-pressure water jet (Fig 3).

Alternatively, but a bit more time consuming, the bar’s top layer of insulation can be destructively removed and the stator-winding strands can be “peeled out”, either in groups or one-by-one. Certain bar configurations may have single, wide strands simply layered on top of each other, much like a generator field winding. But generators with high ratings may have configurations of multiple-strands wide by many strands high—for example, six strands wide ×20 strands tall. Peeling is relatively easy in the first case, the second not so much.

It may be questioned that the core lamination insulation will be damaged by the high-pressure water jet, and it is certain that the insulation on the edges of the laminations will be impacted. However, the voltage is very low and industry experience with multiple methods of stator-core slot cleaning and repairs, followed by “suitability for service” testing to industry-acceptance criteria for core iron/insulation, confirms that interlaminar insulation remains unaffected.

The water jetting process is restricted to the slot sides and bottom, and both the water jet tip and pressures are specifically chosen to effect only removal of the epoxy. Since some slots are very narrow, this can complicate removal methods and, in some instances, use of a precisely selected rotating tool (specific wheel material, size, depth control, etc) may be required.

As with all stator rewinds, conventional or GVPI, once the process is completed, the entire stator undergoes standard acceptability testing—including high-flux and EL CID testing.

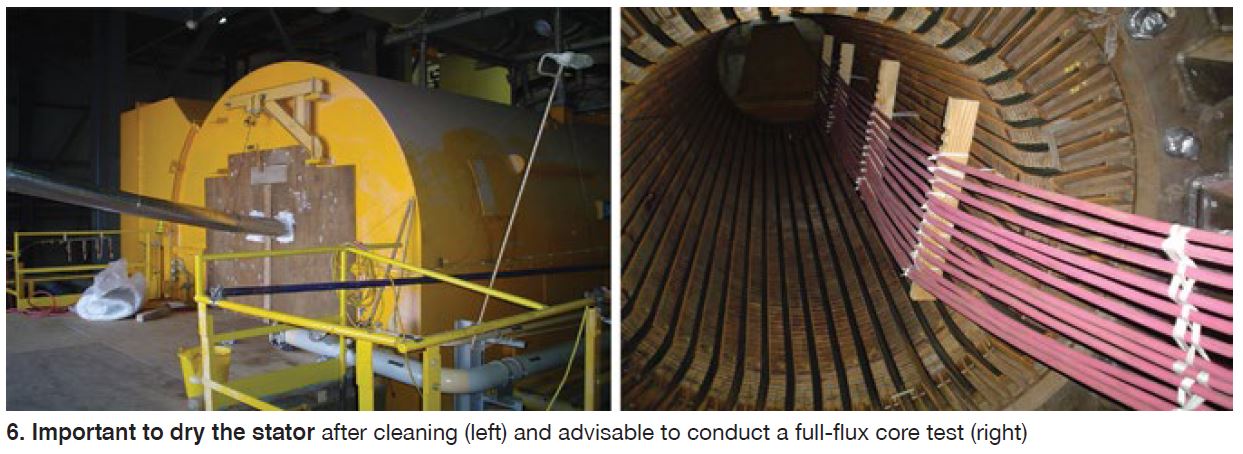

With the bar insulation removed, the bars can be extracted with some difficulty using procedures similar to those used on a convention winding (Fig 4). Once the bars are out, the core can be cleaned with dry ice, vacuum, and/or brushing (Fig 5). Dry out will be needed and full flux core test advisable (Fig 6).

After the core is clean and dry, and has satisfactory flux test results, winding installation can proceed as with a normal winding. CCJ

Acknowledgement: Clyde V Maughan contributed to this article.