With the 2023 Combined Cycle Users Group (CCUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of the CCUG recap series here.

- See part two of the CCUG recap series here.

- See part three of the CCUG recap series here.

Condenser explosion? Yes, you read that right

During an abnormal plant outage, and precipitated by faulty fuel isolation valves, natural gas accumulation in the steam turbine/generator condenser led to a catastrophic explosion which rocked a 2 × 1 combined cycle but fortunately did not injure or kill anyone, and caused only minimal equipment damage.

Before this event, no one at the plant imagined that fuel gas could build up inside the condenser. And if you can’t either, you owe it to yourself and your colleagues to view the slides.

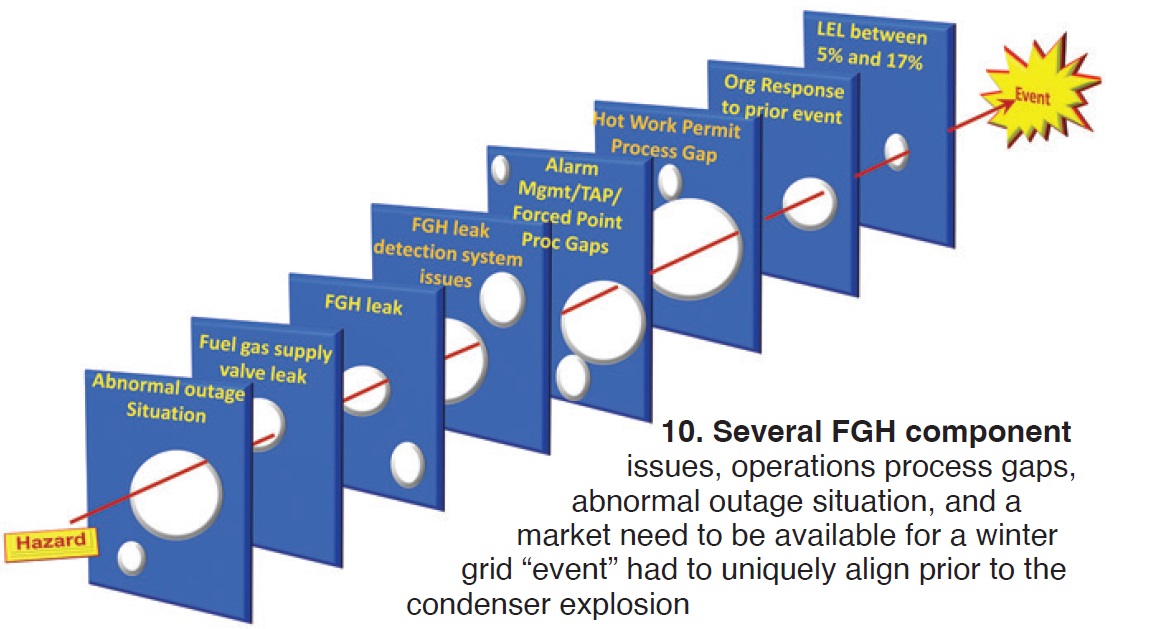

One of the unique aspects of the 11-day outage was that the gas turbines were being held in a state of readiness to support the grid during a period of extraordinary demand. That meant fuel-line pressure was being maintained up to the fuel-gas heater (FGH) valves. Unbeknownst to the plant staff, one or more of the heat-exchanger tubes were not plugged sufficiently, the heater’s fuel leak detector wasn’t working properly, and the isolation valve leaked (Fig 10).

When a welder came to repair a 1-in line on the outside of the condenser, the arc ignited the fuel in the condenser, six rupture disks on top of the unit blew out (and were later found strewn throughout the plant site), bolting holding the center LP turbine cover failed and the cover lifted about 6 in. The truly unfortunate factor in all this was that the fuel gas accumulated to within the relatively narrow explosive limit range of 5% to 17%.

This presentation should win an “all conference” award, not only for the clarity of the content but the owner/operator’s subsequent efforts to ensure that the learnings permeate the industry. The must-view slide deck will be especially instructive for anyone at plants with gas performance heaters getting the heat from the HRSG’s intermediate-pressure water supply lines.

You’ll be rewarded with a cogent list of a relatively large number of fleet-wide recommendations being undertaken by the owner/operator, which are then tailored to each individual plant—surely an excellent starting point for the many other plants with similar design features.

There’s gold in them thar gaps!

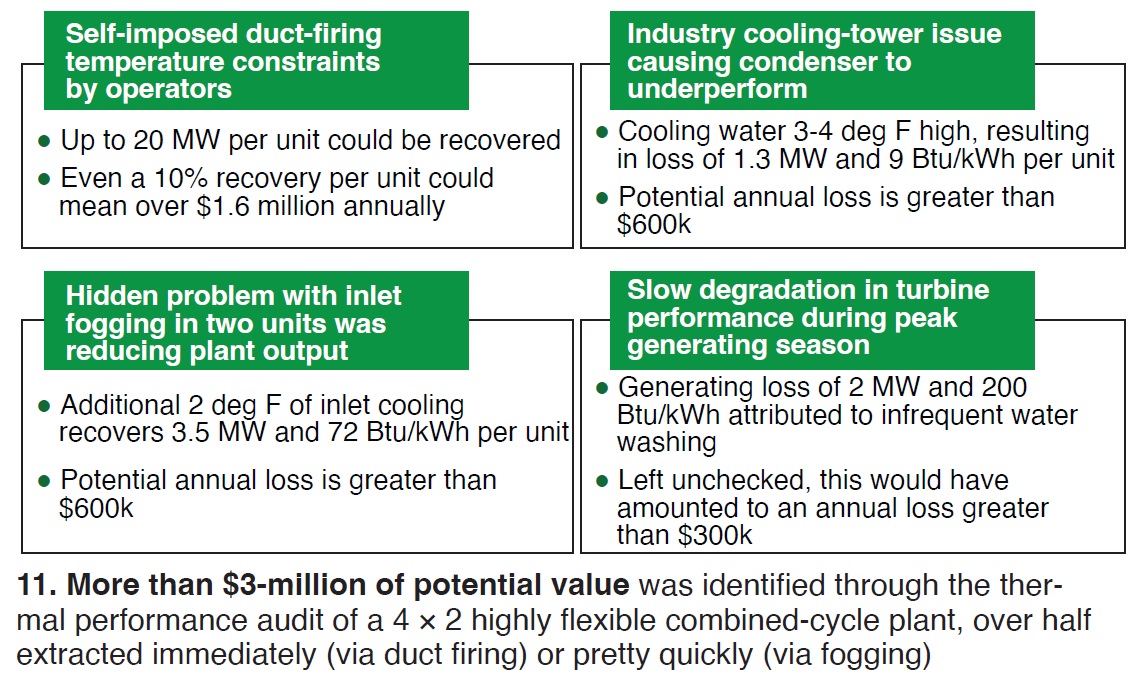

Hidden value can be unlocked through a thermal performance audit and addressing gaps to restore performance, stressed Jeff Schleis, EthosEnergy. Case study results reveal valuations from $300,000 to $1.6-million annually (Fig 11) by undertaking the modest actions recommended in the report issued to the client. Assessment is based on interviews with plant staff, six months of operating data (with remote access to the historian), and plant design data.

“CCGT Performance Is Key to Net Zero”

ST/G valve issues, repair strategies

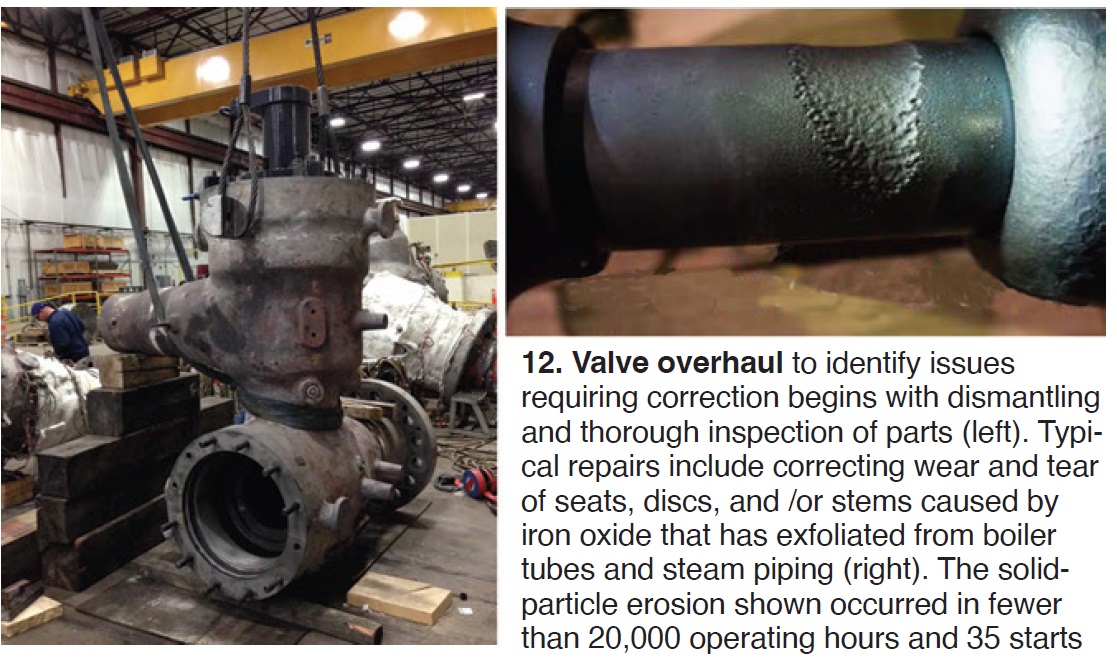

If you have main steam valves approaching three to five years in age, or 25,000 hours of operation, MD&A’s minimum recommendation for inspection and repair, you owe it to yourself to view these slides presented by Dale Gould and Dean Casey. This is especially true if you are past the first five years of plant operations, when valve issues begin to rise. There are no industry or independent maintenance practices, only OEM guidelines, for these valves in combined-cycle facilities, making presentations like this one even more valuable.

Generally, inspection and repair are targeted at: restoring clearances to OEM specs—such as bushing removal and replacement, hardened inserts, and scale removal; achieving concentricity, so that the valve operates precisely on its centerline; sealing and resurfacing to ensure no steam cutting; and attending to foreign-object barriers, such as strainer baskets. Case studies replete with photos drive home main points.

“Steam Turbine Valve Common Issues”

HGP parts—understanding, mitigating risks

All hot-gas-path (HGP) components for life extension have associated risks, Mechanical Dynamics & Analysis’s Jose Quinones, stressed, whether they are OEM new, OEM repaired, third-party repaired, third-party new, or originating from other users. His overriding message is that there are options to evaluate and mitigate these risks, illustrated with “quick” case studies showing how three third-stage blades from three different GT models were assessed, and how two led to successful life extension and one (not cooled internally) did not.

“Unintended Reliability Risk Through Part Replacement/Obsolescence”