With the 2023 Generator Users Group (GUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website. See part one of this GUG recap series here.

Stator-bar failures traced to insulation voids

Stator-bar failures traced to insulation voids

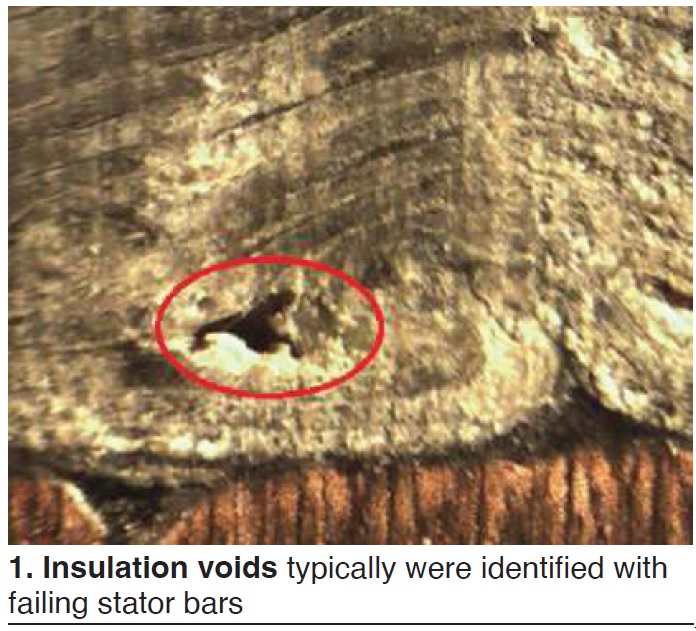

A member of the GUG steering committee spoke about his company’s experience regarding premature failures of stator windings attributed to manufacturing issues. Of particular concern was that some failures occurred even after all electrical tests had been passed. Resulting lost production obviously had a negative impact on the bottom line.

Most of the failed bars had voids in their insulation (Fig 1)—typically in the transition/bend area. Speaker reviews the types of tape available and the pros and cons of using each, plus proper taping procedures, electrical testing, etc. Rewind issues at two of the utility’s plants contribute to the learning experience.

“Stator Winding Manufacturing Issues”

Learn from experience gained by colleagues

Learn from experience gained by colleagues

A major utility’s four-person generator brain trust shares its findings on the topics below—nuggets for virtually every owner/operator.

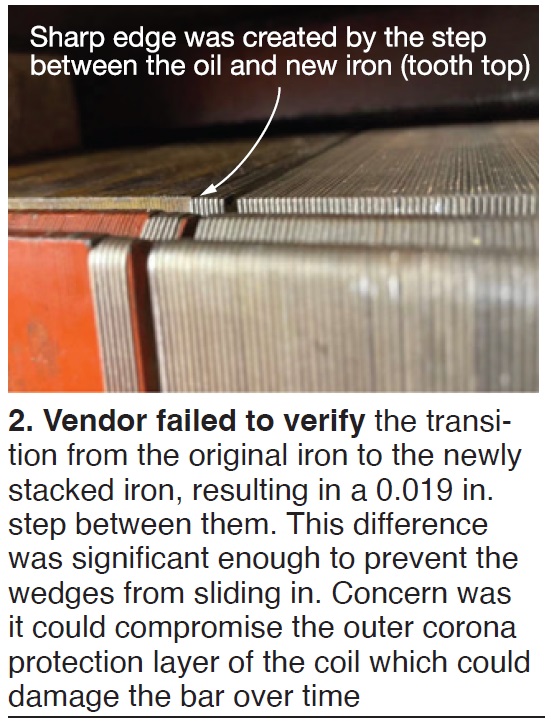

- Stator rewind lessons learned: winding support-cone findings (misaligned phase-lead banks), step found between new and existing iron after restack (Fig 2), bottom coils damaged during installation, modified wedges to prevent partial blockage of core vents, FME event.

- Partial rewind resulted in a full rewind: OEM used third-party winders. Their lack of experience and familiarity with winding design contributed to extensive growth in project scope, plus work quality issues. Bar and tie damage were a result.

- Use of improper materials: Capping compound used for series connections was of an older formulation than used today, with lower thermal transfer properties. This resulted in specialized online monitoring post rewind and potential derate of the machine. The fix requires installation of a new inner nozzle shield to increase cooling.

- Bar manufacturing issues, in particular a lack of consistency in the shape of replacement bars which caused tolerance, alignment, and bar-to-bar spacing issues.

- Non-seg bus phase-to-phase fault.

- Generator terminal and PT-cabinet water intrusion.

Why proper alignment is critical to rewind success

Speaker provides a valuable backgrounder on the importance of correct alignment of stator-endwinding support system components during a rewind and follows with a case history of what went wrong on the rewind of a 7A6 generator when new connection rings were not properly supported during installation. Key elements of the presentation include the following:

- A review of the stator winding support system, including core iron/frame and slot components (filter materials and slot wedging system). Plus, endwinding support components.

- A review of the purpose of the support system, including: mechanical support the stator winding, allow for thermal expansion/contraction, and minimize/restrain dynamic forces during normal operation and fault events.

- Imperative that the endwinding support system is correctly aligned prior to winding installation. Challenges such as the complex 3-D shapes of stator bars/coils are covered. Points to remember: The installed position must accommodate thermal expansion without binding, provide adequate spacing to prevent the risk of voltage stress, and assure a uniform and symmetric endwinding assembly to withstand operational forces and fault events.

“Importance of Correct Alignment of Stator Endwinding Support System Components During Rewind”