With the 2023 Generator Users Group (GUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

- See part one of this GUG recap series here.

- See part two of this GUG recap series here.

- See part three of this GUG recap series here.

HV bushings—inspection, testing, failures

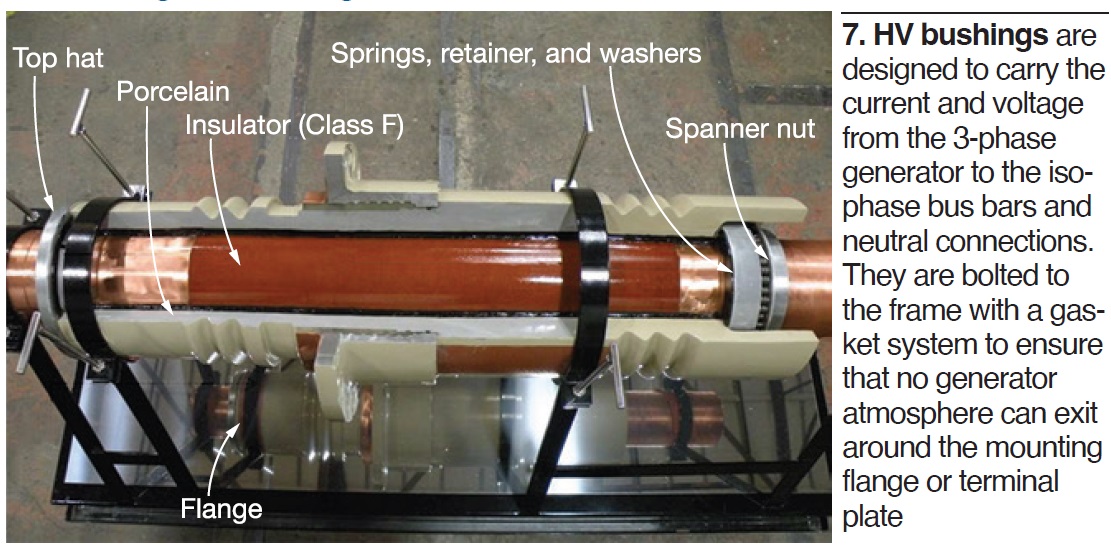

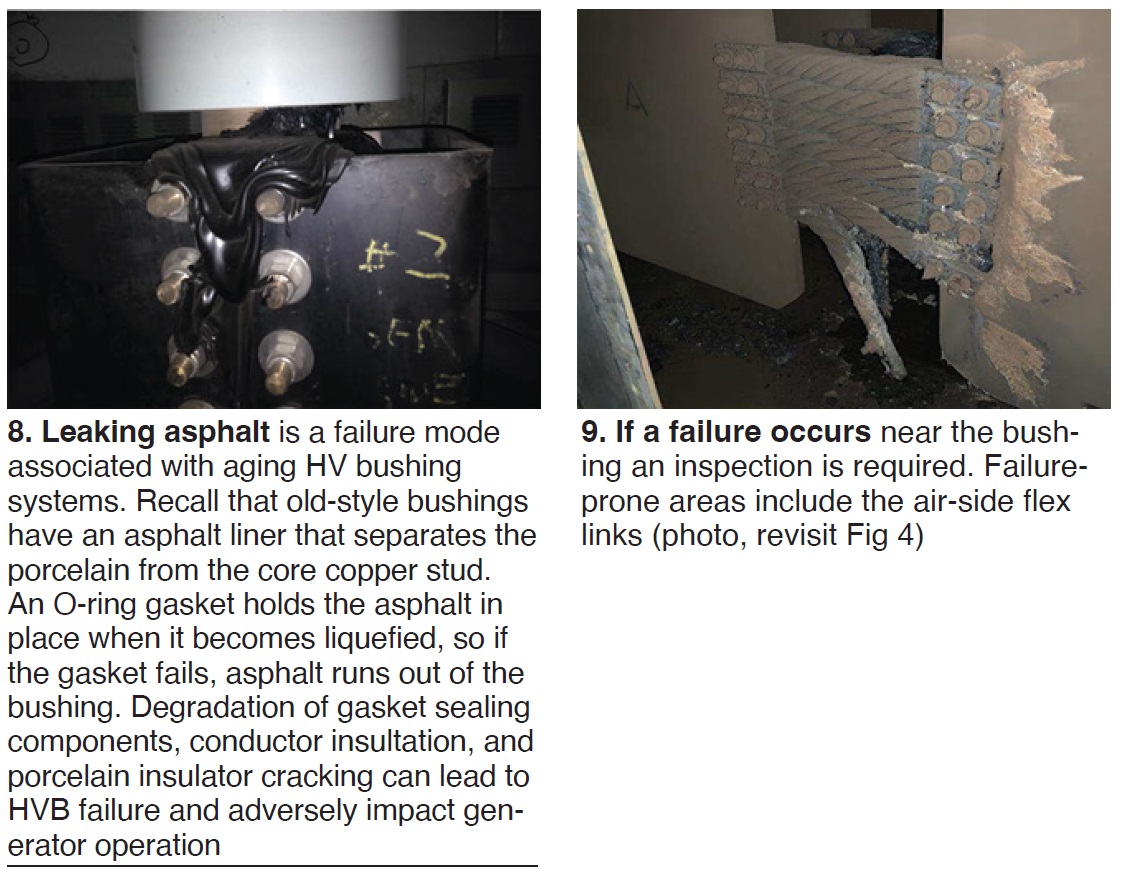

James Joyce, MD&A’s generator repairs operations manager and a popular participant in user group meetings, presented a comprehensive tutorial on the inspection, testing, and maintenance of high-voltage bushings (HVB) at the 2022 GUG conference. The slide deck is highly illustrated with many excellent photos, such as those in Figs 7-9. The presentation is of value to anyone having HVB responsibilities.

“High-Voltage Bushings—Inspection, Testing, Manufacturing, and Failure Examples”

Bus-duct failure investigation

Case history begins with a review of the basics of isophase bus-duct design, including topics not typically covered in presentations on IBD at most industry conferences—such as induced voltages and resulting current flow in the various types of enclosures: discontinuous or insulated, continuous bonded, and discontinuous bonded housing arrangements.

Inspections were focused on locations where current may flow that it shouldn’t and where current can’t flow that it should.

“Generator Bus Duct Circulating Current Issues”

Focus your attention on the things causing you problems

Sounds like a no-brainer, but the retired former owner’s engineer, who made a career out of fixing problems, offers valuable advice, especially for those new to generator O&M. Consultant Jim Stone began with a few words on viewpoint, noting the following:

- Everyone is trying to make a profit.

- Everyone is short/tight on expertise.

- The less they know/have, the more you must know/have.

- If no one does it, it won’t get done.

Next, he reviews how generators fail—mostly for mechanical reasons:

- Insulation fails from debonding, delamination, voids, cracking organic breakdown, abrasion, and/or contamination.

- Things break, caused by high-/low-cycle fatigue or overload (usually thermal).

- Things loosen.

- Things stick, wear, catch, lose resilience, etc.

The capacity to discern is critical, he says. Someone has to know what’s what and what matters every step of the way. That can be you or someone you hire who does. Or you can rely on supplier experience. Remember: Having someone look who doesn’t know, adds nothing.

The expert also offers his thoughts on the complicated nature of generators, the need for good specifications, the importance of design reviews, inspections and test plans, the value of documentation, commissioning, the perils of nonconformance, and what to track during manufacturing and construction.

“Getting What You Want—that is, Ensuring Quality”

Online diagnostics for generators

Thomas Laird, a principal electrical systems engineer for PSM, begins his presentation with the requisite list of products and services available from his company and its sister firm, Thomassen Energy. Next, he discusses key steps in PSM’s generator major and minor inspections and how the company uses online diagnostics to assist in outage planning.

Focus is on electromagnetic signature analysis (EMSA), using a radio frequency current transformer (RFCT) to assess rotor, excitation, and isophase condition. A flux probe is used to assess field-winding condition.

Anyone involved in outage planning would likely benefit from a review of this slide deck.

“Using Online Diagnostics to Assist in Generator Outage Planning”