With the 2023 Power Plant Controls Users Group (PPCUG) approaching August 28-31 in Atlanta, part of the greater Power Users Combined Conference, reviewing some of the content from last year’s meeting should encourage you to attend or send someone from your organization to experience this valuable content in person. Presentation abstracts below are based on information available only to end users in the slide decks posted at www.powerusers.org. Those seeking deeper dives into specific topics should note the presentation titles in italics at the end of each summary and access the source material on the website.

Migrate to EGD Mark VI-to-Ovation Interface

A representative from Emerson explains how to migrate from a “traditional” GSM-to-Ovation interface to an Ethernet Global Data (EGD) interface and the many advantages which can accrue to the user—including accessibility of Mark VI alarm and events, avoiding an OPC connection thereby increasing communication speed, availability of monitored points in all Ovation applications, and capability to run in parallel with Mark VI HMI. The direct interface sets the stage for remote start/operation, single-window control room, Mark VI HMI replacement, and advanced supervisory functions in Ovation.

“Direct EGD Interface with GE Mark VI and Mark VIe”

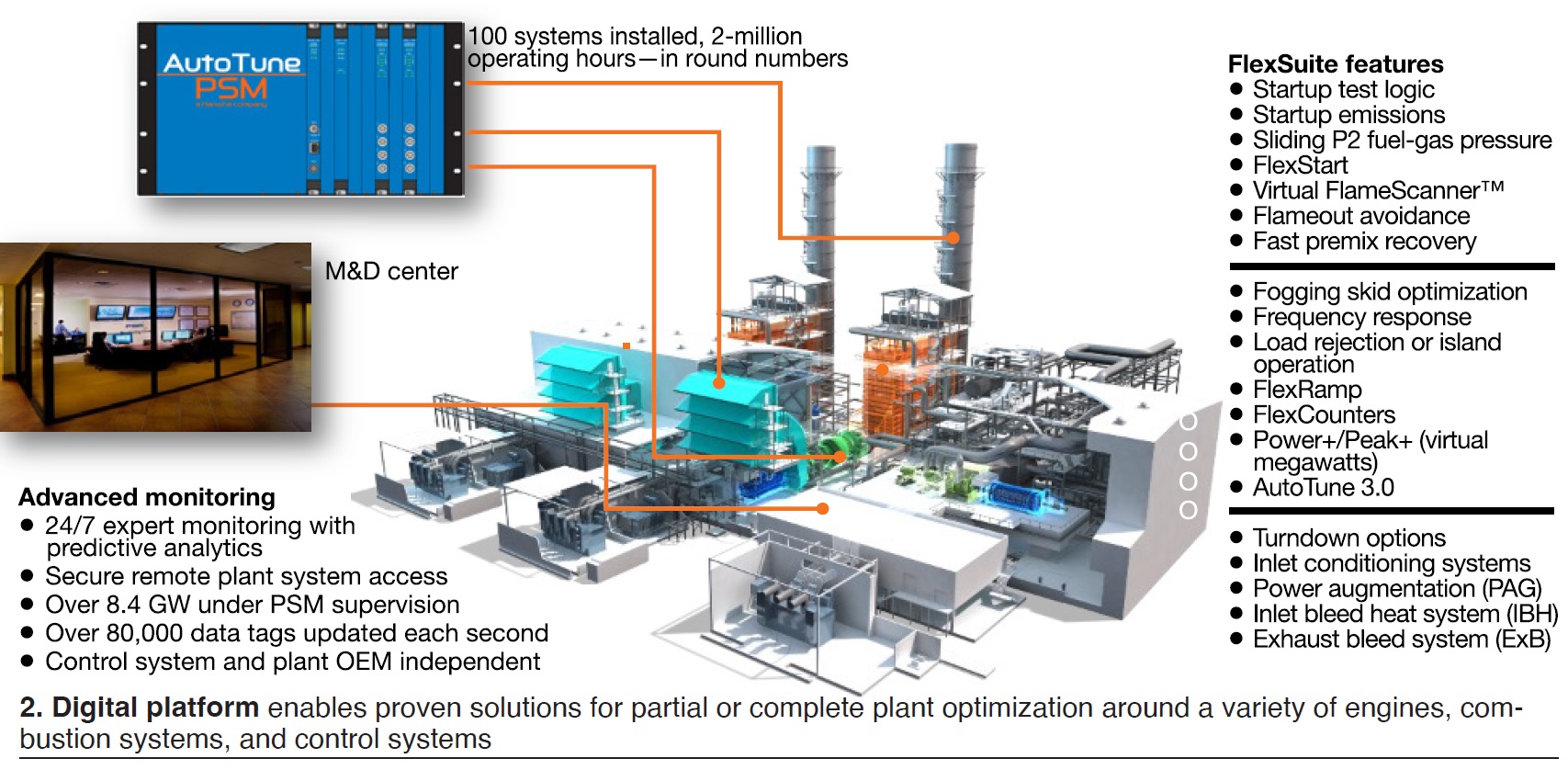

Full suite of control, M&D solutions

Katie Koch, PSM, made clear that PSM has solutions for optimizing your control and M&D systems, and they include assistance with 24/7 M&D, optimization algorithms (Autotune, FlexRamp, FlexStart, and FlexFuel), hardware and interface replacements and upgrades, fleet-level benchmarking, actionable intelligence for performance improvements, and even a full digital twin. Twelve engine platforms, eight combustion systems, and nine control systems make up the company’s experience base with these solutions.

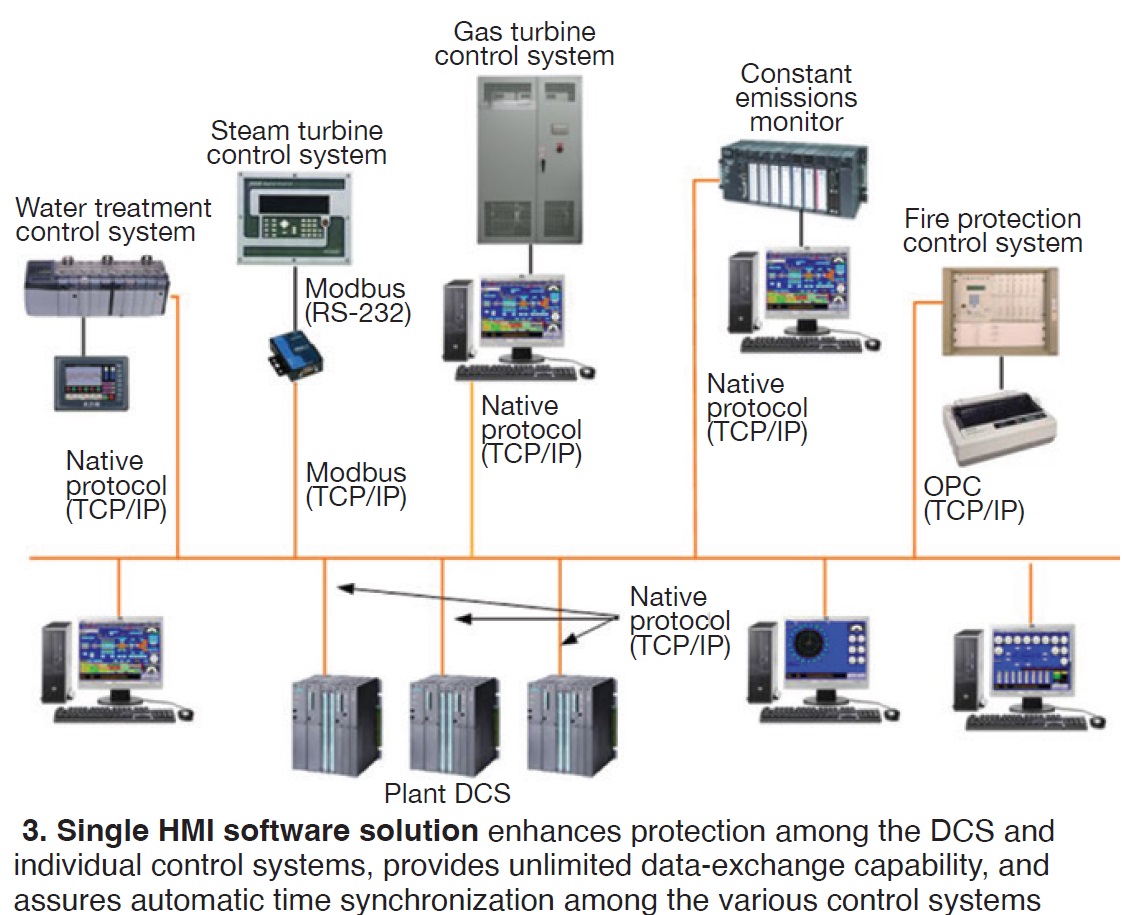

Single HMI, control retrofits

MD&A’s Control Systems Division offers a variety of services for steam turbines, gas turbines, and generator exciters ranging from consulting and field engineering (including owner’s engineer) to replacement parts for legacy systems. Presenter Joe Hovorka dwelled at length on MD&A’s IBECS HMI which unifies and simplifies multiple legacy control system HMIs into one interface. IBECS is compatible with all major digital turbine controls, Hovorka noted. Seven case studies are presented, with attached one-page summaries of successful recent projects.

“Controls and Excitation Overview”

Automate generator gas-manifold purge

Mark Williams, Environment One Corp, stressed that automating the purging process can significantly reduce purge time required, consume less CO₂, and protect personnel in the event of an emergency. Slides review options for automating valves, tie-in points, example P&ID, and sample automation purge screen.

“Operator- Initiated Generator Purge/DHCP Upgrades”

Remedies for real-world controls issues

The range of issues detailed in this presentation from a seasoned controls expert working for a major fleet owner/operator almost defies current trends in user conference presentations. Each issue may not apply at your plant, but together they comprise almost a control engineer’s log of issues and remedies.

Included are turbine-oil leak-detection alarm, water ingress into GT exhaust and accumulation under the plenum from offline water wash, excessive gas flow at startup (TIL2319), enhancement of ECC correction algorithm for UCSB (TIL2290), auto NOₓ bias adjustment, liquid fuel system reliability, emergency bearing oil pump test prior to startup, steam injection bias, compressor bleed valve (CBV) flow issues, action of CBVs during startup, load commutated inverter (LCI) cross-connect, and isochronous control.