The 2023 symposium of the Gas Turbi ne Energy Network (GTEN), held in October 2023 in Banff, Canada, and reviewed earlier in the year (CCJ No. 77, p 96), included many presentations on hydrogen, proposed as a key fuel for a “net-zero world,” when no additional carbon is being discharged to the atmosphere. GTEN focused on gas turbines for pipelines, petrochemical facilities, and in other industrial settings, in addition to their widespread use in electric power generation.

ne Energy Network (GTEN), held in October 2023 in Banff, Canada, and reviewed earlier in the year (CCJ No. 77, p 96), included many presentations on hydrogen, proposed as a key fuel for a “net-zero world,” when no additional carbon is being discharged to the atmosphere. GTEN focused on gas turbines for pipelines, petrochemical facilities, and in other industrial settings, in addition to their widespread use in electric power generation.

As illustrated in the summaries below, several of the experts were attuned to the realities of hydrogen as a fuel, especially for non-electric applications, rather than assuming that H₂, as a net-zero strategy, is a fait accompli.

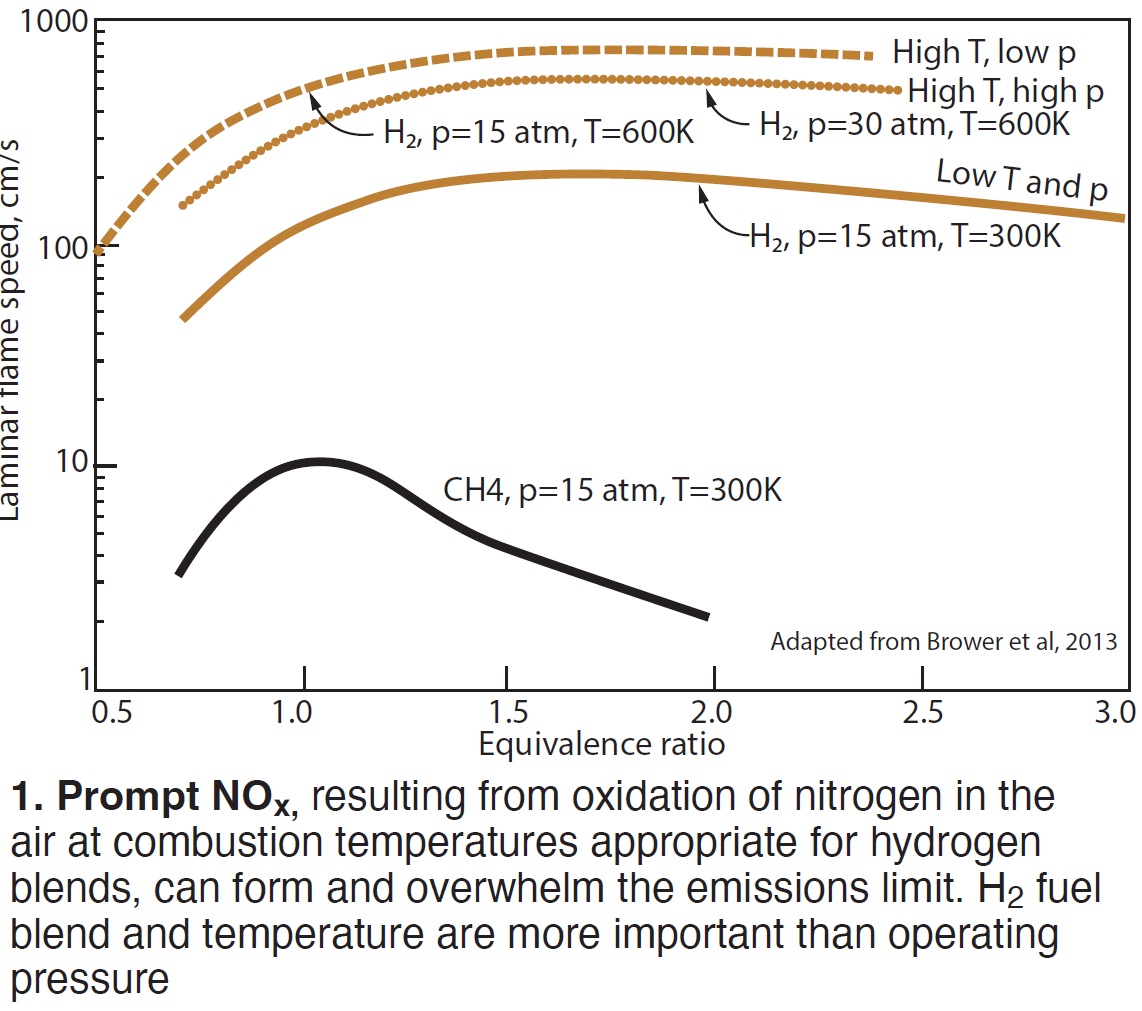

H₂ for Gas Turbines—a Technical Overview, Griffin Beck and Brian Connolly, Southwest Research Institute. Presenters dove into the intricacies of hydrogen combustion versus natural gas and other fuels. The fuel blend percentage and combustion temperature are more important than pressure, they stressed. Additional “prompt NOₓ” (Fig 1) can form from the oxidation of nitrogen in the air (as opposed to the fuel) at the higher combustion temperatures. H₂ can improve flame stability and extend the lean blowout limit compared to NG. But flashback hazards are amplified.

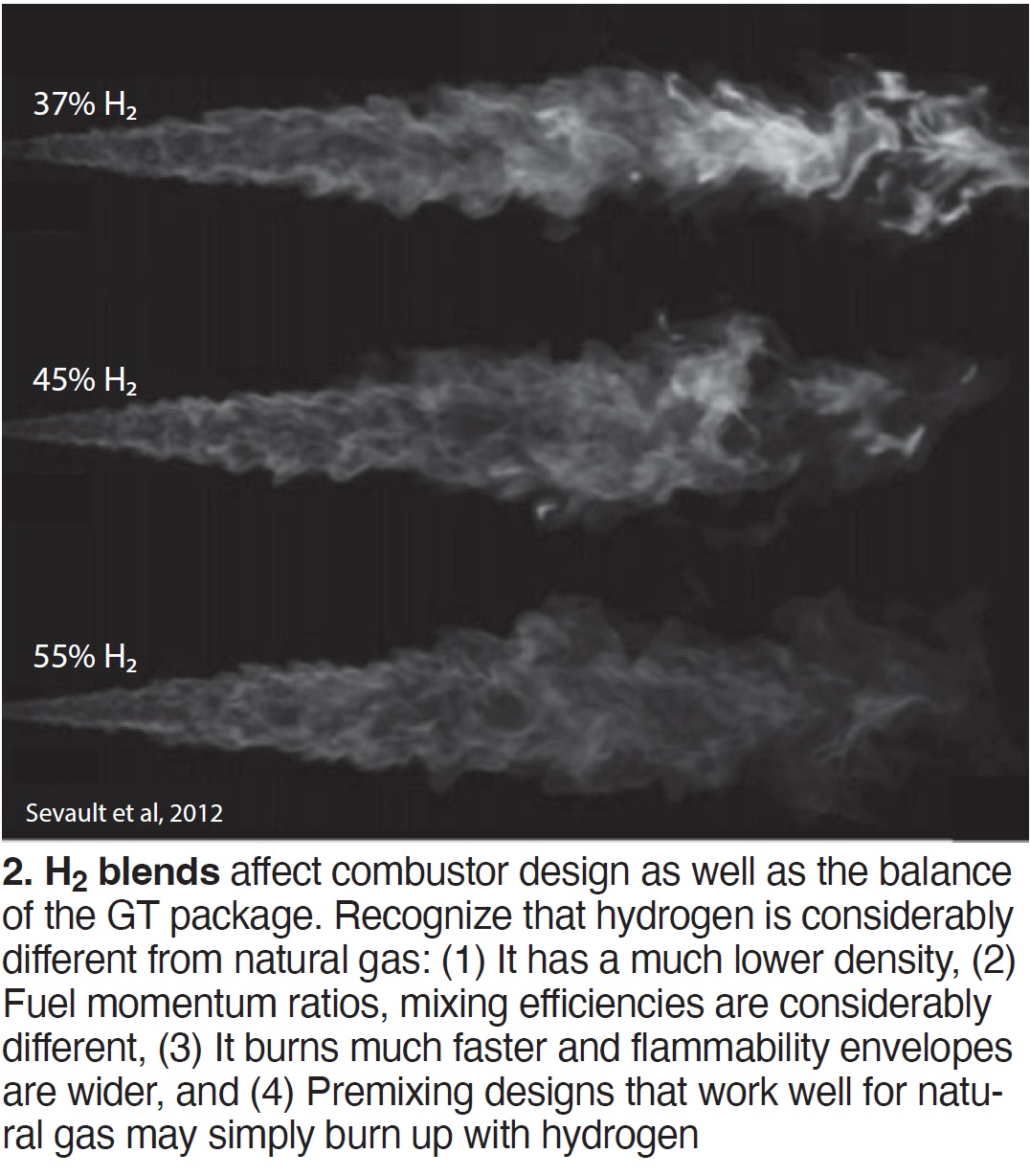

New gas-turbine designs employ micro-mixing nozzles in the combustor to achieve high H₂ blends. However, there are design challenges (Fig 2) in the areas of (1) flashback (flames can back-flow into the fuel lines and injectors), (2) hot spots (poor mixing, high NOₓ, non-uniform heating), (3) large volumes of gas (H₂ requires more oxygen), (4) auto-ignition (H₂ auto-ignites at a wide range of concentrations), and (5) the Joule-Thompson effect (at process temperatures, H₂ heats when expanding).

There are also impacts on the balance of the GT package. For example, combustion products contain more water vapor and heat transfer is higher. Both could introduce new corrosion risks in the hot gas path.

Prerequisites for the Use of Low-Carbon Alternative Fuels in Gas Turbine Power Generation, Antonio Escamilla, ETN Global/University of Seville. Alternative fuel-composition standards—such as for ammonia, biofuels, e-methanol, and others—lag other areas of technology development. These fuels are not primarily produced for use as a fuel in GTs, presenter observed.

Example: Ammonia’s exact composition is not known, so there’s no good design basis for exhaust gases from combustion or interactions with the extremely sensitive alloys used in GTs. Industry needs to address this by developing new testing methodologies and measurement techniques.

Impacts of H₂ Blending on Mainline Natural-Gas Compression, David Campbell, Enbridge. Up to 20% hydrogen blends raise the parasitic power consumption of the compressor by up to 25%. Thus, the GT consumes more fuel to maintain an equivalent amount of natural gas moving through the pipeline, raising the specter of more carbon discharged rather than less. On top of that, a 20% blend in the pipeline drops its energy content by 14.5%.

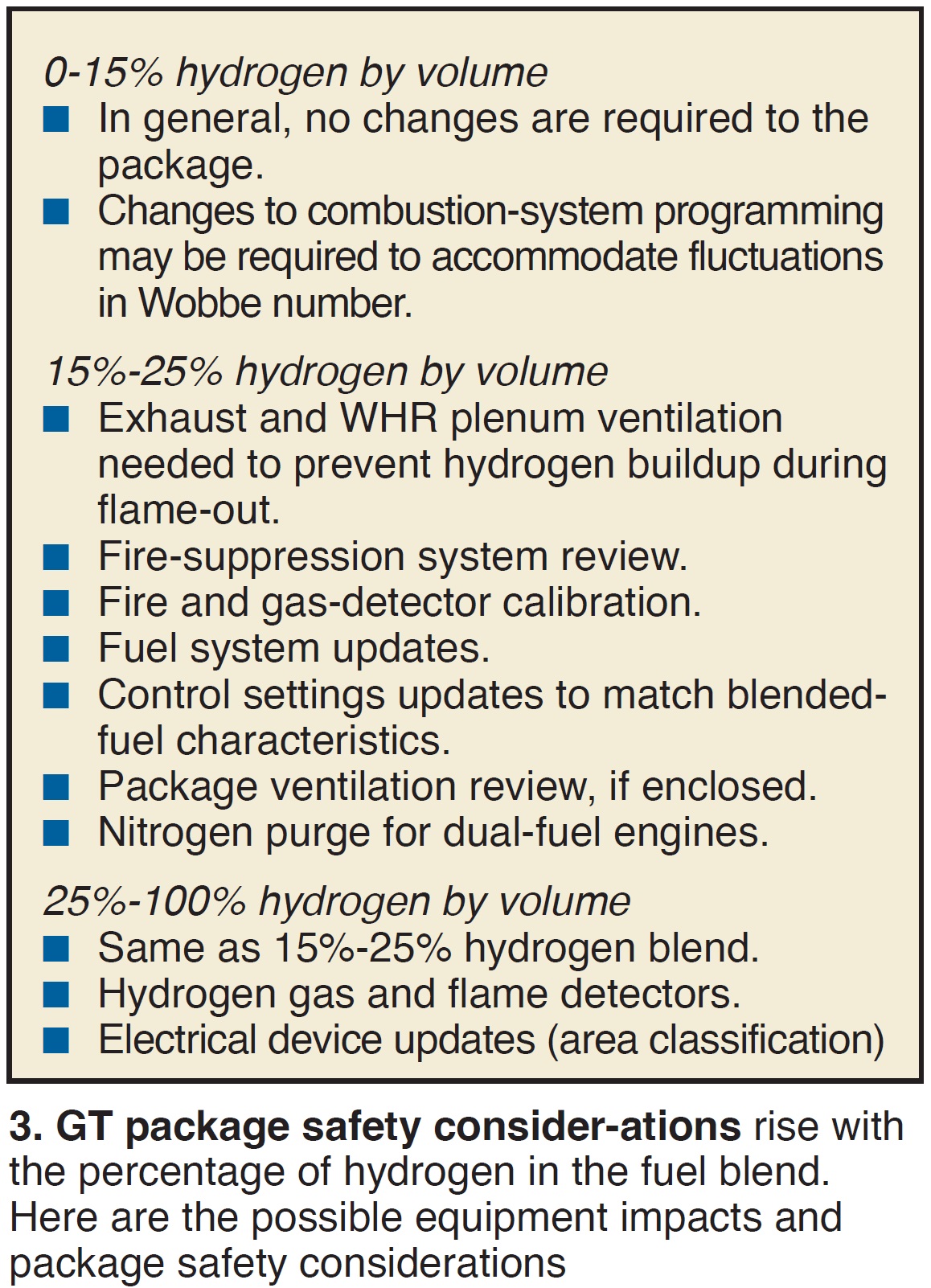

This is in addition to the equipment impacts (Fig 3) noted elsewhere—such as flashback, auto-ignition, and combustion instability. Presenter suggests that 20% blends in pipelines are probably achievable after review and equipment modifications, but 2.5%, ramping up to 5%, is a good initial goal.

Decarbonizing the Gas Turbine Fleet: Combustion Solutions to Meet Today’s and Future Energy Demands, Hany Rizkalla and Katie Koch, PSM. Company’s “FlameSheet and LEC combustor technologies offer “tri-fuel applications for plant-wide decarbonizing: refinery off gas (to avoid flaring), natural gas, and hydrogen. FlameSheet has now been demonstrated for up to 60% H₂/NG blends and requires “minimal changes” to use the same combustor in multiple GT frames.

How Energy Systems Change: The Energy Transition in North America, David Burns and Brooke Cuming, Enbridge. Company plans to produce and export up to 1.4-million tons annually of so-called blue/green ammonia and other e-fuels by 2028. Hydrogen can be produced via electrolysis using inexpensive (and carbon-free) renewable electricity and stored in pipelines and salt caverns. Presenters note that ammonia has 70% more energy than H₂, an important parameter when considering long-distance transport.

Industrial Gas Turbines in a Decarbonizing Environment, Rainier Kurz and others, Solar Turbines Inc. Presenters introduce concept of a dual-drive package with a gas turbine/electric motor, separated by clutches, to power centrifugal compressors on pipelines. Generator/motor can be used to augment gas-turbine power and produce electricity when compressor is operating at low loads, as well as add a level of security to keep the pipeline operating during electricity outages. In other words, dual drive offers arbitrage (gas and electricity market costs and contract prices) and optimization of emissions, energy sources, and equipment availability.

Practical Oilfield Applications of H₂ Electrolysis, Richard Ens, Alberta H₂, and Mark Kuppe, Acero Engineering Inc. Focus is on the Dynamic Brine Electrolysis (DBE) process to generate and use H₂, and potential advantages over traditional ion-exchange membrane, alkaline electrolysis, or solid oxide electrolysis. Key components are bipolar electrolytic cells relying on induction capacitance, which is said to allow easier plate cleaning and replacement.