Editor’s note: During the main-session presentations at HRSG Forum 2023, Duke Energy and Structural Integrity Associates Inc (SI) jointly presented on an online “HRSG damage monitoring system,” which is highlighted in CCJ’s summary report of that conference.

At the same Forum last June, Jacob Boyd presented “Wireless high-energy-piping monitoring program,” recently implemented at his plant, CPV’s St. Charles Energy Center in Maryland.

Both topics were expanded during the two-hour webinar reviewed below, “Real-time damage monitoring of HRSG components,” held Nov 7, 2023. View recording of that event, coordinated by CCJ and HRSG Forum, at the end of this page. What follows are selected highlights of what you will see and hear in this webinar.

Monitoring at Duke Energy

Structural Integrity’s Kane Riggenbach introduces the webinar while Duke’s Eugene Eagle reviews for listeners his company’s damage monitoring system. They offer a real-time assessment of system performance and component integrity for both HRSGs and high-energy piping (HEP). The webinar focuses on Duke’s goals, implementation, significant results, and future plans.

The online monitoring system begins with existing plant monitoring equipment for temperatures, pressures, steam flows, and valve positions. Duke and SI then add specific temperature instrumentation (in this case, 64 thermocouples per unit). All data feed into Structural Integrity’s PlantTrak™ software, relayed to SI through a secure VPN connection. Company analysts then look for indicators and trends that affect creep and fatigue life, and monitor high-temperature alerts and other abnormalities specific to the HRSG components.

The reference plant (Fig 1) has three triple-pressure HRSGs behind Siemens F-class gas turbines that have accumulated 70,000 service hours since 2012. Currently in baseload, the plant is moving into cycling operation, expected to increase wear and tear on the units.

The purpose of the new monitoring system is to look more closely at these high-temperature components susceptible to creep, fatigue, corrosion fatigue, oxidation, and exfoliation:

- Interstage attemperators.

- Bypass superheaters.

- Intermediate headers and tubing downstream of attemperators.

- Branch connections.

- Final-stage outlet headers.

- Drums.

As Riggenbach summarizes, this “allows you to dig deeper into what might appear to be acceptable results.”

The webinar offers data comparisons for operating modes, comparisons between units and sites, the effects of low-load operations, operating with and without steam sparging, and the impacts of startup time changes.

One key benefit discussed is help in targeting inspections, setting inspection times and budgets, and basically, states Riggenbach, “finding the problems before they find you.”

As Eagle explains, “These are big and important units for Duke. They are highly efficient, and if we can get maximum life out of them while ramping them a bit harder, or cycling them more, we can get the most value out of these assets.”

Kane then addresses specifics of instrumentation which he says are “now more specific to component life management than simply process variables.” He explains that detection (instrumentation) is now looking at both magnitude and frequency of events. Such monitors look at temperature differentials, ramp rates, over-temperatures, and other items. This leads to trending, analysis and diagnostics, and setting priorities.

At this point in the webinar, some questions and answers are monitored by Co-chairs Barry Dooley, Structural Integrity, and Bob Anderson, Competitive Power Resources.

An interesting caution for older HRSGs: Historical operating data could be difficult to obtain and verify. Also, system and component changes over the years might not be well documented.

Other questions discussed include benefits to parts supply and storage, fitness-for-service predictions, and benefits to control-logic changes.

High-energy piping

Jacob Boyd then discusses wireless HEP monitoring at the 2 × 1 St. Charles Energy Center, a program implemented with SI. This plant, commissioned in 2017, has fast-start 7FA.05 gas turbines, a D-11A steam turbine, and CMI HRSGs. The plant cycles 140 to 170 times per year.

In late 2019, the site experienced a through-wall leak at the girth weld of a hot-reheat (HRH) bypass line. Root cause was thermal fatigue. Plant personnel worked with SI to install local thermocouples to better assess thermal transients during operations.

The presentation includes descriptions of data collection nodes and e-mail notifications, highly valued at St. Charles because of limited engineering and walkdown staff.

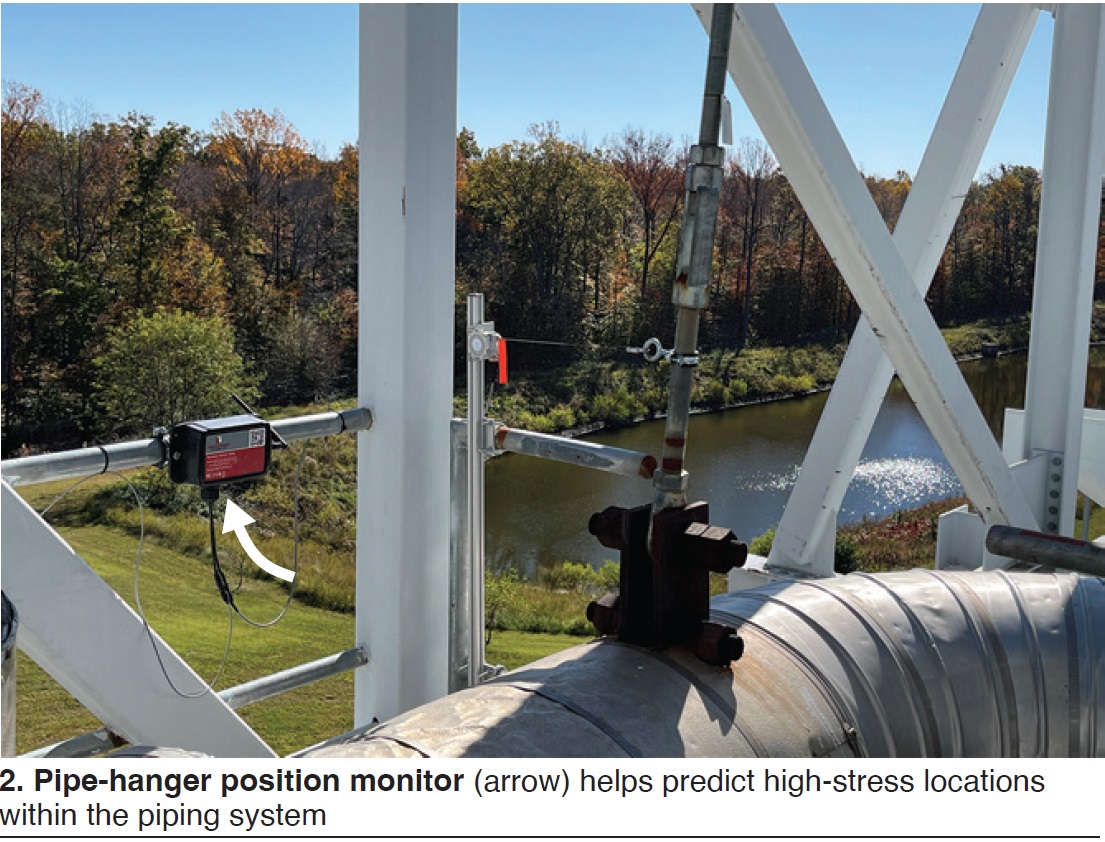

Cycling concerns led to wireless monitoring of the HEP system, again working with SI (Fig 2). HEP monitoring examples highlight a growing area of concern at many plants.

At this point in the webinar, questions are again coordinated by Dooley and Anderson.

More data

SI’s Wes Bauver, follows with various case-study examples of other damage monitoring systems.

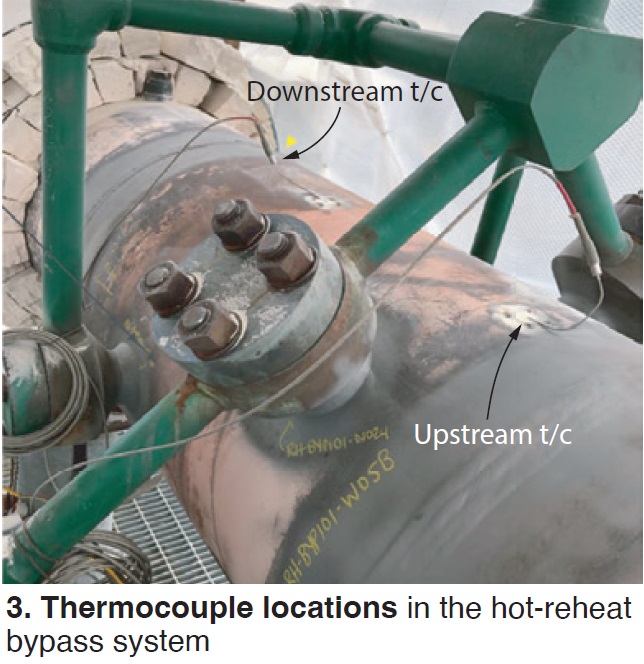

This includes discussion of HRH bypass thermocouple locations (Fig 3), circumferential data with thermocouples at 12:00, 3:00, 6:00 and 9:00 locations, and results of data over time.

Bauver looks at a specific HP-to-CRH bypass event, and data indicating non-uniform attemperator spray and indications of possible bypass-valve leakage.

Next is an interstage attemperator thermocouple arrangement recommended for older units: specific locations relative to spray nozzles, elbows, and liners. Discussions cover lessons learned through comparing spray flows and steam flows on two units over time.

He shows a bypass system with thermowell instrument locations relative to valves, and discusses temperature differentials relative to elbows, bypass valve, and bypass piping. Data plots show differentials recorded during startups from 2016 to 2022, and unit comparisons.

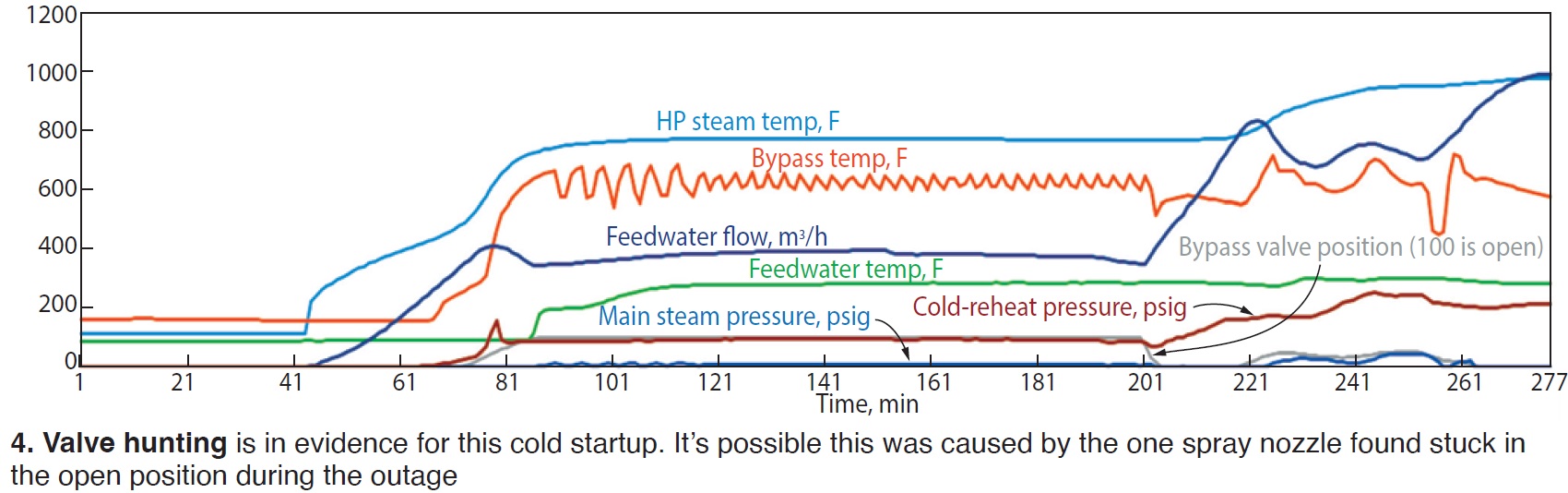

Bauver ends with a look at typical cold starts and graphic evidence of valve hunting (Fig 4).

The fundamental point for all of the above: the more data, the better.

The webinar then offers a recap of the primary benefits of online monitoring:

- Targeted inspection locations and intervals.

- Extended inspection intervals or delayed inspections.

- Expedited fitness-for-service evaluations.

- Optimized component life management.

- Improved confidence in unit reliability.

This ends with a discussion on future use of monitoring technology, including the use of various ultrasonic transducers to monitor metal thickness during operation.