- Equipment design, materials, and corrosion.

- Operational constraints and optimization.

- Component replacement, maintenance, and operating costs.

- Strategies for optimizing inspection, maintenance, and cyclic operation.

- Workforce, management, and automation issues.

- Europe is going through the same market changes as North America. Cycling is global.

- Some countries have more cycling and low-load experience than North America—such as those with geothermal and hydroelectric plants that cause varied operation of fuel-fired assets. This experience base has wide-ranging value.

- Europe and Japan are taking active roles in high-temperature materials development and testing.

The ETD conference

Key themes were engineering design, materials R&D, new inspection techniques, cost analysis, and plant management/maintenance. Optional pre-conference training courses centered on operation and maintenance (Day One) and both short- and long-term system preservation (Day Two). The agenda was divided into two parts. The first half discussed plant flexibility including new developments in creep-fatigue interaction in high-temperature plant materials. The second half focused on new developments in plant preservation, maintenance, inspection, monitoring, repair, and life assessment. Selected highlights from the seven sessions are given below.“Who wins when plant components fail?”

This question launched a presentation by David Allen (Impact PowerTech Ltd, UK) a consultant to ETD, on the upgrading of materials and welds. His next question was equally pointed: “Why do we so often stick with last-century technology?” Allen first captured attention with a philosophical discussion of planned obsolescence. He cited interesting examples from the automobile, white goods, and communications industries. Participants were captivated, and on alert for more. Allen did not claim current evidence of planned obsolescence within the power industry, and in fact stated that a manufacturer with a unique design is careful to maintain its good reputation. But he did note some dangers similar to those expressed by Eskom (South Africa) at last year’s Air-Cooled Condenser Users Group meeting in Las Vegas. We all experience the ongoing pressures for low bids, rapid investment payback, and increasingly stringent trading conditions. The potential menace is commonly applied standards that fail to ensure the most reliable long-term component operation. In other words, once a supplier meets the standards or codes in the specification, further refinements or improvements can become less important (and more expensive) to the supplier. The same is true on qualifying bids for component supply. Providers’ reputations are at less risk as long as they meet the qualifications. Perhaps because “innovation brings risk,” or because “regular repair and maintenance activities provide jobs,” we could be letting ourselves down, suggested Allen. And in his words, “We are still building new plants with 40-year-old materials (P91, Alloy 617) and ignoring the newer, potentially better alternatives.” And how has market-driven flexible operation changed things? “Cycling makes it worse!” Details have become clear, stressed Allen:- Flexible operation only makes service exposure more onerous.

- Thermomechanical transients cause additional cyclic loading:

• Mechanical and thermal fatigue cracking.

• Creep-fatigue cracking (with creep ductility exhaustion attributed to repeated transient creep strain).

• Creep cracking (with creep life reduction caused by increased loading).

- Poor temperature control can severely shorten creep life.

- Creep issues do not go away; they get much worse.

- Fatigue brings additional challenges.

- Sticking with last-century technology increases risk!

- Thinner components minimize thermal/mechanical mismatch loading and may therefore perform better when fatigue is a problem.

- But thinner components will experience higher pressure stresses and may therefore perform worse when creep is a problem!

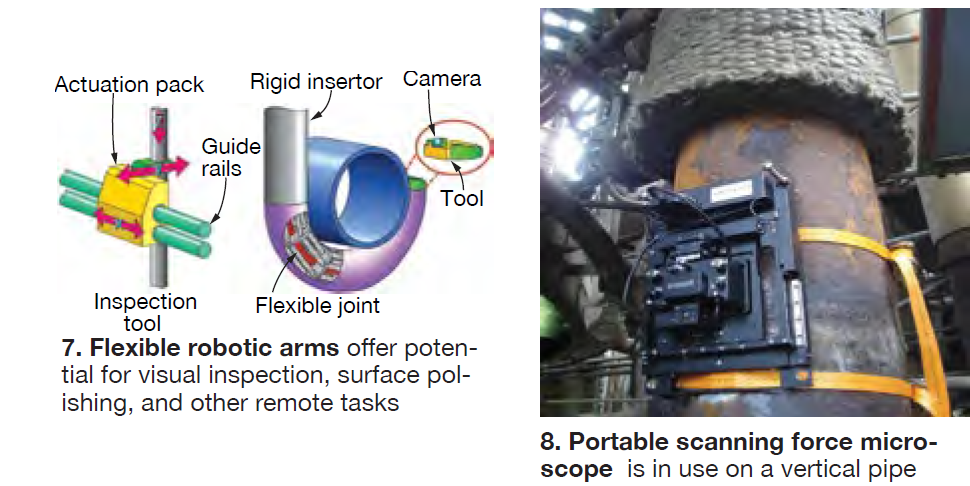

- The four most creep-brittle casts, with long-term average area reduction (Ra) in creep test values in the range of 3% to 12%, all had normalizing times in the range of 0.2 to 0.6 hours.

- The seven next most creep-brittle casts, all with Ra values in the range of 18% to 24%, had normalizing times of 0.2 to 1.0 hours.

- No cast with a normalizing equivalent to 2 hours at 1050C or 1 hour at 1070C had a long-term Ra value lower than 28%.

MarBN alloy

MarBN alloy

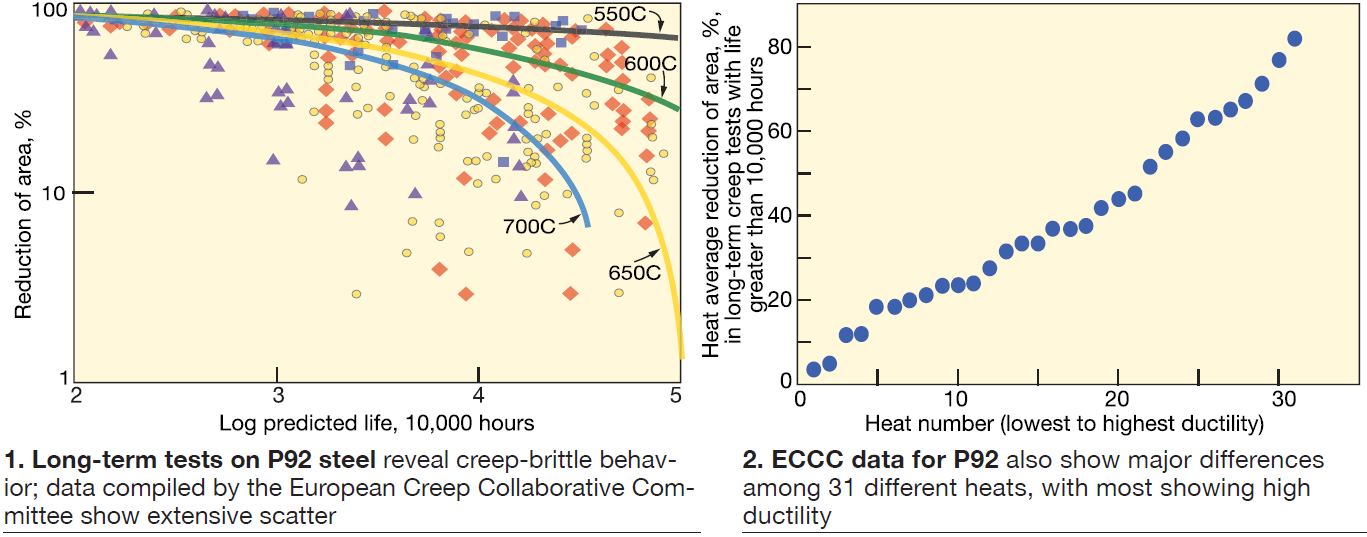

Zhuyao Zhang, Lincoln Electric Europe, followed with MarBN filler-metal development work from Impel and Impulse, two collaborative power-industry research programs in the UK. Intended applications include castings and forgings for steam-turbine components and steam piping (up to 650C). One slide included creep strength predictions (Fig 3).

His summary:

- The development of matching filler metal for MarBN alloy, Chromet 933 SMAW electrode has achieved encouraging progress.

- The weld-metal chemical composition is optimized.

- Satisfactory ambient tensile strength, ductility, and impact toughness have been achieved.

- Satisfactory high-temperature (550C to 700C) tensile strength and ductility have been achieved.

- Results of initial short-term stress rupture tests showed considerable increase in creep strength compared with P92 weld metal at the same conditions.

- Work continues.

Aberrant P91 life predictions

Shibli and David Robertson of ETD tag-teamed an in-depth presentation on life-prediction concerns for aberrant P91 components, often found in powerplants worldwide. They are usually the product of not understanding the precise heat-treatment requirements, by the component producers and fabricators, for high-Cr martensitic steels. They issued a stark warning: “Traditional NDE techniques do not show damage in P91/P92 until late in life (70% or later), making current detection and component integrity management difficult.” New techniques are needed. “A problem with 9Cr martensitic steels,” they said, “is that the creep cavity size for the first 70% of life can be on the nanometer or few-microns level only. Thus cavity detection and quantification by traditional means, such as replication or UT inspection, can be difficult.” At the same time, “for aberrant microstructures powerplants often assume the safe life is equal to P22 or P91. But the industry could be underestimating life, thus condemning these components too early and thereby losing revenue. We currently do not have long-term rupture strength data for such abnormal microstructures to predict their safe operating life accurately.” The two presenters gave examples of potentially abnormal materials:- Material over-tempered or tempered high in the ASME range.

- Material under-tempered at the bottom of the new ASME range (730C) or old range (704C).

- Cooling too slowly from austenitizing.

- Soft spots and soft bands found in some piping materials.

- Various repairs and weld-repair configurations/geometries.

- Repeat weld repairs.

“To make matters worse and life assessment more difficult,” he continued, “it is now fairly well established that the creep failure stages for high-Cr martensitic steels (P91/P92) are reduced to creep cavity initiation, cavity growth, and failure with little warning.”

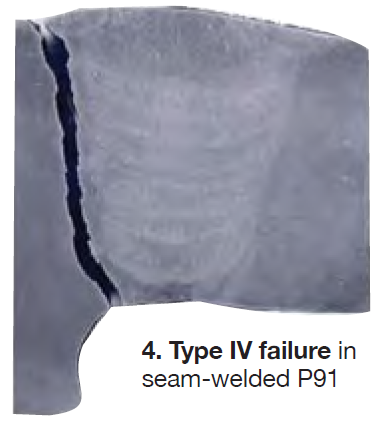

Specific visual examples were given for all points made in the presentation. Featured in the examples was Type IV damage in seam-welded components (Fig 4).

“The 9Cr martensitic steels have been very useful in raising powerplant temperatures and pressures (and making HRSGs more compact), improving plant output and efficiency,” Shibli stated. “However, more and more of these components are now showing cracking at the Type IV position associated with the weldments.”

And their conclusion: “Even components that can be identified to be at risk are creating issues for the plant owners and integrity assessors in view of the unknown long-term rupture strength of the aberrant steels, hence the need for the long-term stress rupture data to ensure their safe operation.”

“To make matters worse and life assessment more difficult,” he continued, “it is now fairly well established that the creep failure stages for high-Cr martensitic steels (P91/P92) are reduced to creep cavity initiation, cavity growth, and failure with little warning.”

Specific visual examples were given for all points made in the presentation. Featured in the examples was Type IV damage in seam-welded components (Fig 4).

“The 9Cr martensitic steels have been very useful in raising powerplant temperatures and pressures (and making HRSGs more compact), improving plant output and efficiency,” Shibli stated. “However, more and more of these components are now showing cracking at the Type IV position associated with the weldments.”

And their conclusion: “Even components that can be identified to be at risk are creating issues for the plant owners and integrity assessors in view of the unknown long-term rupture strength of the aberrant steels, hence the need for the long-term stress rupture data to ensure their safe operation.”

More on materials

Other materials-related presentations included the cyclic loading and cyclic oxide conditions (Federal Institute of Materials Research & Testing, Germany), assessment of welds under creep, fatigue, and creep-fatigue loadings (University of Stuttgart, Germany), dissimilar metal welds in ultra-supercritical powerplants (Belgian Welding Institute), stress corrosion cracking in T24 material (VGB PowerTech Service GmbH, Germany), and microstructural evolution of P91 in high temperature conditions (INAIL, Italy).HRSG revamp for GT upgrade

Pascal Fontaine, CMI Heat Recovery Systems (Seraing, Belgium), discussed example HRSG modifications to match a gas-turbine upgrade. King’s Lynn Power Station in the UK is a high-efficiency, baseload combined cycle commissioned in 1996, designed for peak firing up to 370 MW. The plant is of Siemens single-shaft design with a 120-MW steam turbine and CMI vertical, triple-pressure, unfired HRSG. The operating difficulty became inflexibility to market conditions. Thus, the unit was mothballed in 2012, but significant residual life remained in the plant infrastructure. In 2016, owners signed contracts to revamp the plant and targeted more than 300 starts per year. The gas turbine and generator would be replaced, and the HRSG upgraded to match the new conditions, including new steam piping and attemperation systems. One street would be added to the air-cooled condenser. Final superheater/reheater modules are now being replaced by two Euro Norm modules with additional heating surface. Fontaine’s presentation walked systematically through the dismantling/replacement processes, including details of pipe-to-header welding and inlet duct restoration. King’s Lynn will return to commercial operation in 2019.Cyclic-tolerant options

In a later conference session, Fontaine returned to discuss developments toward more cyclic-tolerant HRSGs—both horizontal and vertical designs. A key part of this was the question: “What are the root causes of fatigue damage?”- Heat exchanger construction (stiffness between tubes).

- Superheater drainage.

- Tube/header connections (thin wall to thick wall).

- Economizer steaming.

- Cyclic stress fatigue of drums, specifically HP.

- Desuperheater design and risks of water quenching.

Thermal transient impacts

Richard Walton, SSE (formerly Scottish and Southern Energy Plc), addressed the group on thermal transients and their impacts throughout the SSE fleet, suggesting more targeted inspections, monthly monitoring and reporting, trending and investigating, and the need for improved industry guidance. Details of his presentation outlined what he called “up-shock” and “down-shock” events and impacts on the HP and IP systems (superheater and reheater). The benefits became recurring conference themes:- Better inspection scope forecasting.

- Reduced risk of on-load failure.

- Reduced risk of forced outage.

- Issue identification and reduced costs of both maintenance and inspection.

- A managed approach to life extension.

Change the inspection philosophy

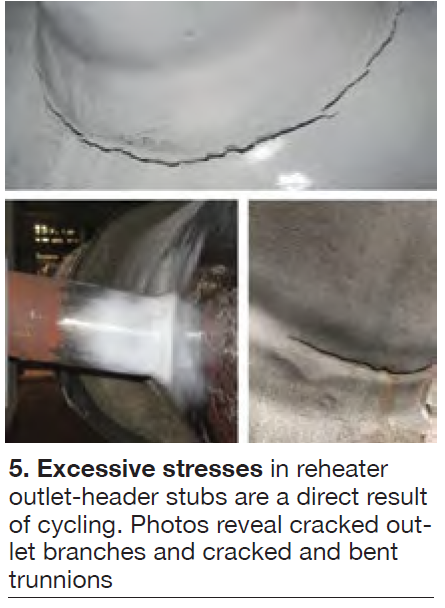

James MacArthur, senior engineer, pressure systems, was also present from SSE and discussed the effect of UK grid demand on HRSG damage mechanisms. Running plants on demand is “arduous,” he stated, but one tactic is to “change the inspection philosophy.” His example was a 735-MW plant with two HRSGs, recently converted from baseload to two shifting, commissioned in the mid-1990s, and experiencing 900 starts in the past three years. He reviewed fatigue-related damage locations: reheater tube stubs, reheater outlet and inlet headers, and superheater headers. For the inlet header, a combination of system stresses and poor attemperation led to corrosion fatigue failure (a common topic). He also reviewed pipework stress analysis, indicating that “even with all supports operating correctly, stresses in the header stubs are high.” Problems in his example case were caused by “anomalous and excessive axial stress during operation.” Stress analysis showed inadequate supporting and restraint arrangement on the outlet manifolds (Fig 5). “Even with all supports operating correctly,” he stated, “stresses in the header stubs were high.”

He then turned to both single- and two-phase FAC (flow-accelerated corrosion), pointing out locations, mechanisms, detection, and consequences. “In a combined-cycle plant,” he summarized, “FAC typically occurs in the LP and IP evaporator circuits, HP economizers, and feed pipework.” He pointed out that typical locations in conventional plants are the feedwater heaters and systems, and for all plants in air-cooled condensers.

This leads to the need (common theme again) of reassessing the inspection strategy as well as the impact of expected future operation (cycling).

Problems in his example case were caused by “anomalous and excessive axial stress during operation.” Stress analysis showed inadequate supporting and restraint arrangement on the outlet manifolds (Fig 5). “Even with all supports operating correctly,” he stated, “stresses in the header stubs were high.”

He then turned to both single- and two-phase FAC (flow-accelerated corrosion), pointing out locations, mechanisms, detection, and consequences. “In a combined-cycle plant,” he summarized, “FAC typically occurs in the LP and IP evaporator circuits, HP economizers, and feed pipework.” He pointed out that typical locations in conventional plants are the feedwater heaters and systems, and for all plants in air-cooled condensers.

This leads to the need (common theme again) of reassessing the inspection strategy as well as the impact of expected future operation (cycling).

Benchmarking, cycling analysis

Feroza Akther (ETD) reminded participants of the common impacts of cycling, including a note that owner/operators should also be aware of “higher fuel consumption during startups and shutdowns because of inefficient heat transfer and non-optimal heat rate.” Therefore, owner/operators need to know the technical and financial impacts of converting base-load units to cycling, as well as the operating costs for current cycling units. Her presentation described both benchmarking and analysis for a large group of conventional and combined-cycle units. The plant database included 30 conventional and 65 combined cycle units from Europe, US, and Asia, all with at least seven years of O&M data, ages from 1 to 35 years operation, and net generation from 50 to 500 MW. Analysis included data for:- Modifications.

- Damages attributed to operating conditions.

- Maintenance activities.

- Inspections.

- Availability and reliability factors.

Gen 3

ETD’s Nadeem Ahmed continued this theme with a look at a “Gen 3 RCM-based maintenance and reliability program.” He began with a review of common programs and philosophies, listing the range of acronyms widespread throughout the industry. “Gen 3,” he stated, “combines reliability and scheduled maintenance programs.” It focuses on reliability-centered maintenance, and “seeks the optimal mix of condition-based, time-based, and run-to-failure strategies.” He called it “a risk-based process for determining the least-cost maintenance and surveillance actions needed to meet operating performance targets.” He then outlined implementation phases, including integration into plant operating and monitoring software.Flexible operation studies

Uniper Energy Services’ Scott Lockyer discussed the company’s long-term flexible operation journey and offered thoughts on economic improvement from the operational view. Within this discussion was a process that seemed adaptable to various targeted component and system concerns. The challenge was to minimize damage caused by cycling. The solution discussed:- Appraisal of plant-specific risk areas.

- Fitting of additional instrumentation and performance of flexible operation trials.

- Analysis and understanding of the thermal transients.

- Repeated trials to confirm understanding.

- Detailed stress analysis of at-risk components to help plan future strategies—maintenance, for example.

- Progressive drainage techniques.

- Optimized firing patterns and firing rates.

- Use of excess air.

- More precise temperature matching.

- Faster ramp rates.

- Improved use of attemperator sprays.

More on inspection

Other inspection topics included a boiler-tube inspection program for Southeast Asia’s first ultra-supercritical boiler (TNB, Malaysia), modeling of creep deformation and rupture criteria (Huddersfield Univ, UK), life assessment under creep-fatigue conditions (Univ of Stuttgart, Germany), high-temperature strain mapping in steel weldments using digital image correlation (Univ of Cape Town, South Africa), and DC/AC potential-drop technique for creep damage monitoring in piping systems (Metalect, UK).Don’t forget the piping

Rob Wang, Engineering Analysis Services Ltd (UK), discussed outage planning and life extension of load cycling plants. He highlighted both piping system health management (Fig 6) and analytical techniques for component life assessment.

- Hanger ID and setting positions in both cold and hot conditions.

- Hanger travel limits.

- Movement between cold and hot conditions.

- Dates for installation, effort adjustment/reset and replacement/resetting.

- Pre-outage survey in hot condition.

- Survey during outage in cold condition.

- Post-outage survey in hot condition.

- Survey hangers/supports to obtain hanger position readings.

- Review current readings against as-built benchmark and historical data.

- Identify out-of-range hot positions and predict possible out-of-range cold positions.

- Make outage-team maintenance recommendations for hanger effort adjustments or hanger replacement.

- Survey hangers/supports to obtain position readings.

- Review current readings against as-built and historical data.

- Confirm/verify out-of-range cold positions predicted during the pre-outage hot survey.

- Make hanger support effort adjustments based on pre-outage hot recommendations and the current out-of-range findings.

- Record adjustment details and revised hanger readings.

- Predict out-of-range hot hanger positions.

- Survey hangers/supports to obtain position readings.

- Review current readings against as-built and historical data.

- Check that adjusted hangers are within range.

- Record adjustment details and revised hanger readings.

- Note any potential out-of-range indications.

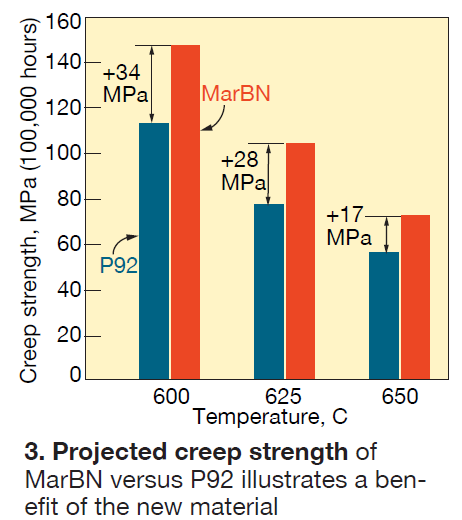

Drones expanded

Capitalizing on a development reported by Xcel Energy at previous HRSG Forums with Bob Anderson, Ahmed Shibli and William Moore issued an extensive report on ETD’s Group Sponsored Project on drones and robots for powerplant inspection. The exploratory phase (just completed) of this project was directed at determining suitability of drones and robots for visual and UT inspection, as well as a review of R&D activities. The upcoming phase is the design and development of the most suitable and economic automated devices in three types: 1. Drones for visual inspection and data analysis of remote, out-of-view and at-height components. 2. Robots for polishing and UT inspection of components including crack sizing. 3. Small or mini-robotic devices for polishing and UT inspection requiring access through narrow spaces—such as between HRSG tubes. 4. Various organizations and experts are involved and more are invited to participate. Drones. One development point is the oil and gas industry, currently using drones for UT inspection by attaching them to pipes. However, drones are not yet stable enough for complete UT inspection. Some significant points were made:- Photos taken by modern commercial surveillance drones can be enlarged on a computer screen by factors greater than 20× before pixilation creeps in.

- Such detail can help diagnose the cause of failures. In the case of a burst evaporator tube, for example, a thick edge can indicate impure feed or boiler water; a thin edge can indicate overheating, fireside wastage, etc.

- This valuable information is available as soon as the boiler has cooled sufficiently for access.