The HRSG Forum, led by Co-chairs Bob Anderson of Competitive Power Resources and Barry Dooley of Structural Integrity Associates, continued its tradition of offering excellent user-driven content in its recent virtual meetings. You can dig deeper by accessing the recordings at https://HRSGforum.com. The HRSG Forum in-person meeting, in collaboration with Power Users for the first time, is scheduled for Atlanta the week of June 12. Details coming soon.

Harold Snyder, PE, of Lakeland (Fla) Electric’s McIntosh Power Plant, began his presentation with a review of a two-decades battle Unit 5, a 1 × 1 501G-powered combined cycle, experienced with high HRSG backpressure (BP) and resultant derating. This facility was commissioned in 2001, one of the plants typical of that era designed for baseload operation but soon pressed into cycling service for many years thereafter.

Almost from the get-go, the HRSG experienced fouling by ammonia salts from the SCR and rust accumulation, most evident in the last tube sections, forcing a gas-turbine (GT) derate of 15 MW.

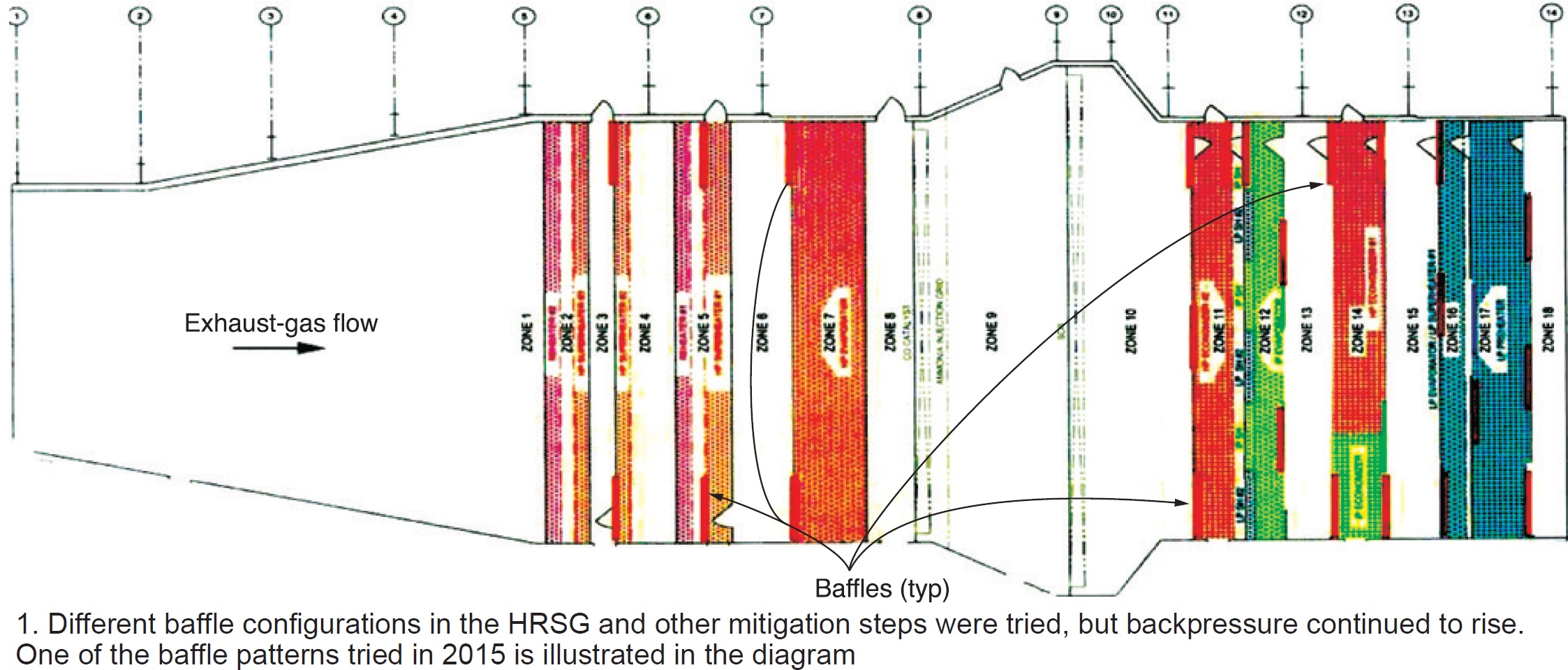

After years of monitoring pressures, trying online cleaning methods (sonic horns, vibrators on lower headers) and offline cleaning (dry ice, air jets, pressure wave), and dehumidifiers on the GT inlet and LP inlet to the HRSG, McIntosh, beginning in 2008, resorted to adding stiffeners in the HRSG, removed lower baffle plates (Fig 1) in the LP and intermediate-pressure (IP) sections (and trying several different baffle configurations), and adjusted SCR controls and economizer recirculation temperature controls, to increase the allowable BP from 28 to 30 in. H2O.

In the face of continued elevated BP in 2016, McIntosh pursued permanent modifications beginning in 2017 (through 2020) to increase allowable backpressure to 45 in. H2O and address other issues—such as tube leaks. These included doubling the number of stiffening plates in the roof, floor, and walls; replacing the LP economizer, LP superheater No. 1, and LP evaporator tube bundles; and upgrading the expansion joints. Eleven tube rows in the LP economizer were replaced with 15 smaller-diameter tubes, creating a 20 in. cleaning lane between the LP economizer and the LP evaporator/superheater No. 1.

Snyder noted, during the Q&A, that pressure-wave cleaning was by far the most effective, stating that the technique was able to remove about five times as much debris as dry ice. Readers are encouraged to listen to all of the Q&A, available at 2022 Recordings (hrsgforum.com), which generated critical discussion and insight into ancillary causes of the BP issues, consequences of different baffling configurations, and other topics. Slides include detailed diagrams of baffle and stiffener configurations and external photos of stiffeners.

The story may not be over, though. The unit has not been cleaned since 2020 and BP is beginning to rise again, reported Snyder, even though the unit is now operating baseload.

Upcoming HRSG Events

|

|

|